In the demanding environment of mining, conveyor belt systems are the lifeline of material handling. Their efficiency and longevity are paramount to operational productivity and cost management. One of the most persistent challenges is the carryback of sticky, abrasive material on the belt return side. This is where secondary scrapers, particularly those equipped with carbide tips, play a transformative role.

The Problem: Conveyor Belt Carryback

Carryback is the residual material that adheres to the belt surface after it passes over the head pulley. While primary scrapers remove the bulk, a thin, tenacious layer often remains. This carryback causes a cascade of problems:

- Belt Mistracking: Accumulated material on the return rollers and pulleys can cause the belt to drift and misalign.

- Roller and Idler Damage: Abrasive material accelerates wear on return idlers, leading to premature failure.

- Structural Damage and Corrosion: Spilled material builds up in the conveyor structure, increasing load and causing corrosion.

- Safety Hazards: Spillage on walkways and around moving parts creates significant slip, trip, and fall hazards.

- Increased Maintenance and Cleanup Costs: Significant labor and resources are consumed in manual cleaning and spillage management.

- Environmental Contamination: Dust from dried carryback becomes an airborne pollutant.

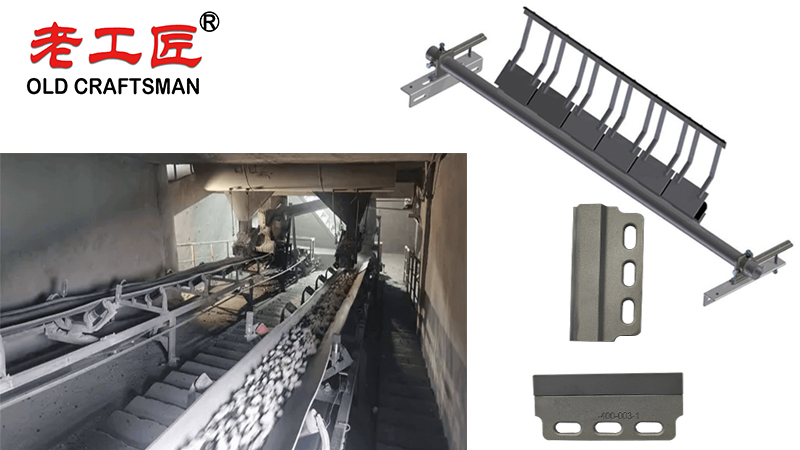

The Solution: The Secondary Scraper System

A conveyor cleaning system is typically multi-staged:

- Primary Scraper: Located at the head pulley, it removes the bulk of the material (e.g., 80-90%).

- Secondary Scraper: Positioned immediately after the primary, its job is to remove the remaining, sticky carryback.

While secondary scrapers can be made from various materials (polyurethane, rubber, steel), carbide tipped scrapers represent the premium solution for harsh mining applications.

Why Carbide is a Game-Changer for Secondary Scrapers

Carbide (typically tungsten carbide) is a composite material known for its exceptional hardness and wear resistance.

| Feature | Benefit for Mining Conveyor Belts |

|---|---|

| Extreme Hardness & Wear Resistance | Outlasts polyurethane and steel by a factor of 10:1 or more, dramatically reducing replacement frequency and downtime. |

| Abrasion Resistance | Ideal for highly abrasive materials like iron ore, copper ore, and taconite. The scraper blade wears slowly, maintaining its cleaning edge far longer. |

| Maintains Sharp Edge | The sharp, durable edge of a carbide blade slices through sticky material rather than pushing it, resulting in superior cleaning efficiency. |

| Reduced Belt Wear | When properly tensioned, the rigid yet finely edged carbide blade cleans effectively without gouging or excessively wearing the belt cover. |

| Cost-Effectiveness | Higher initial investment is offset by dramatically lower long-term costs for replacement blades, labor, and downtime. |

Key Design Considerations for Optimal Performance

Simply installing a carbide scraper is not enough. Proper design and integration are critical to avoid damaging the belt.

- Blade Configuration:

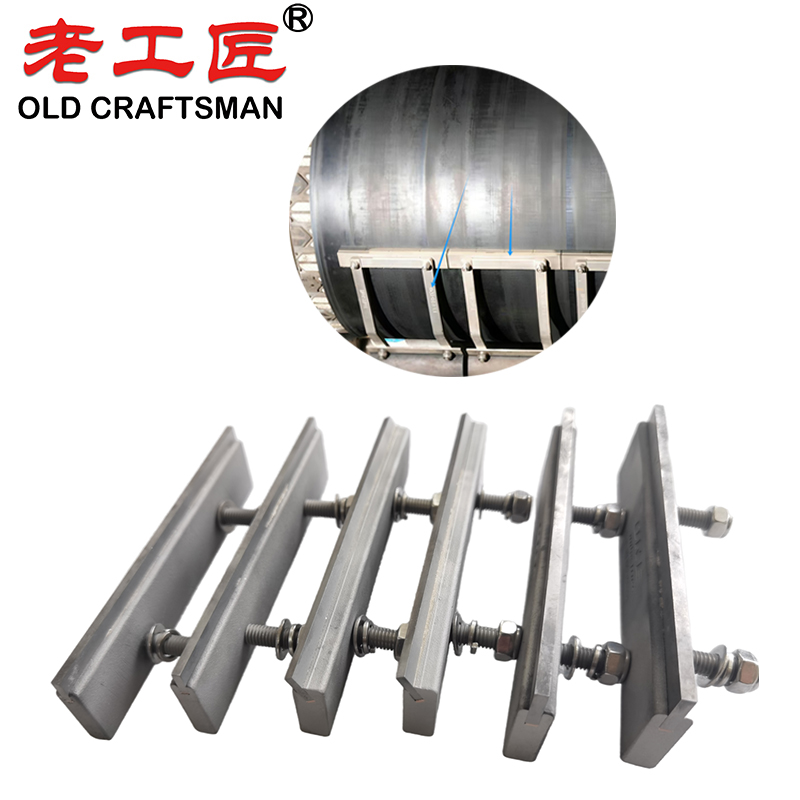

- Carbide-Tipped Segmented Blades: This is the industry standard. Individual carbide tips are mounted in a flexible holder (often polyurethane). This allows each segment to articulate independently, conforming to minor belt imperfections and ensuring even pressure across the entire belt width.

- Tensioning System:

- A consistent and adjustable tensioning mechanism (e.g., torsion spring, pneumatic) is vital. It must apply enough pressure for effective cleaning but not so much that it causes premature belt wear or damage to the scraper. The goal is a clean, whisper-thin wipe.

- Mounting Location and Angle:

- Secondary scrapers are typically mounted 0.5 to 1.0 meters from the head pulley, where the belt is still taut and has left its natural curve.

- The attack angle is precisely engineered (often between 15° and 35° to the belt) to provide a shearing action.

Tangible Benefits: The Bottom Line for Mining Operations

Integrating a high performance carbide secondary scraper system delivers measurable returns:

- >99.5% Cleaning Efficiency: Drastically reduces carryback, virtually eliminating spillage.

- Reduced Downtime: Fewer scraper replacements and less time spent on cleanup and spillage-related repairs.

- Extended Belt Life: By preventing material buildup that causes mistracking and roller jamming, the belt’s lifespan is significantly increased.

- Lower Total Cost of Ownership (TCO): Reduced spending on replacement scrapers, labor, idlers, and belt repairs.

- Enhanced Safety: A cleaner work environment minimizes slip hazards and reduces dust, improving overall site safety.

- Environmental Compliance: Effective dust control helps operations meet stringent environmental regulations.

Best Practices for Implementation and Maintenance

- Correct Selection: Choose a scraper system designed for your specific belt speed, width, and material characteristics (e.g., moisture, abrasiveness, clay content).

- Professional Installation: Ensure the system is installed by trained personnel according to the manufacturer’s specifications.

- Regular Inspection: Check the scraper blades for even wear and the tensioning system for correct pressure during routine maintenance checks.

- Timely Blade Rotation/Replacement: Segmented blades can often be rotated to present a fresh edge. Replace entire segments when the carbide is worn down to the holder to prevent damage to the belt.

Heavy-duty mining conveyor belt scrapers are essential for keeping belts clean in the toughest work environments, from open pit mining operations to high temperature production lines across all over the world. Designed for a wide range of bulk materials and raw materials, these high quality belt cleaners effectively remove stubborn residue, ensuring optimal material handling systems and automation systems performance. By preventing material buildup, they significantly improve efficiency, help move materials smoothly, and reduce long-term maintenance costs. Suitable for specific applications including food processing and other industries with strict hygiene requirements, modern heavy duty scrapers also minimize environmental impact through reduced spillage and dust generation, delivering reliable, long-term performance in demanding industrial settings.

Conclusion

In the relentless environment of a mine, every component must perform under extreme duress. The conveyor belt secondary scraper, often overlooked, is a critical component for efficiency and cost control. By upgrading to a modern, carbide tipped secondary scraper system, mining operations can transform a persistent maintenance headache into a source of reliability.

The investment in carbide technology pays for itself many times over through unparalleled wear life, superior cleaning performance, and the significant reduction of associated operational and safety risks. It is a clear and powerful enhancement for any mining conveyor system striving for peak performance.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding