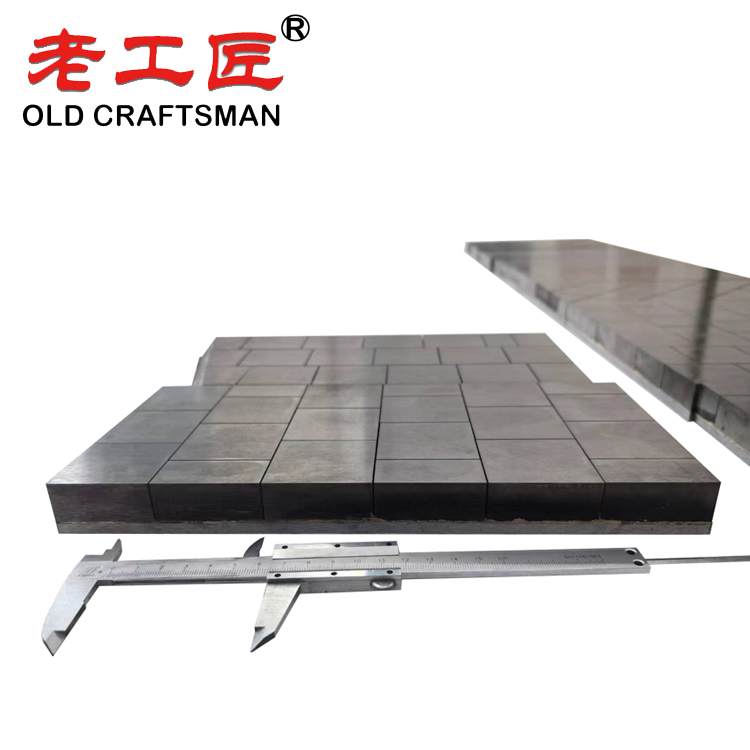

Tungsten Carbide Wear Liner is a protective component used in industrial applications to enhance the durability and lifespan of equipment subjected to high wear and abrasion. It consists of a base material, typically steel or another metal, coated or embedded with tungsten carbide, a highly durable and wear resistant compound made of tungsten and carbon.

Key Features:

- High Hardness: Tungsten carbide is extremely hard (often compared to diamond), making it ideal for resisting abrasion, erosion, and impact.

- Wear Resistance: It protects surfaces from material degradation caused by friction, abrasive particles, or corrosive environments.

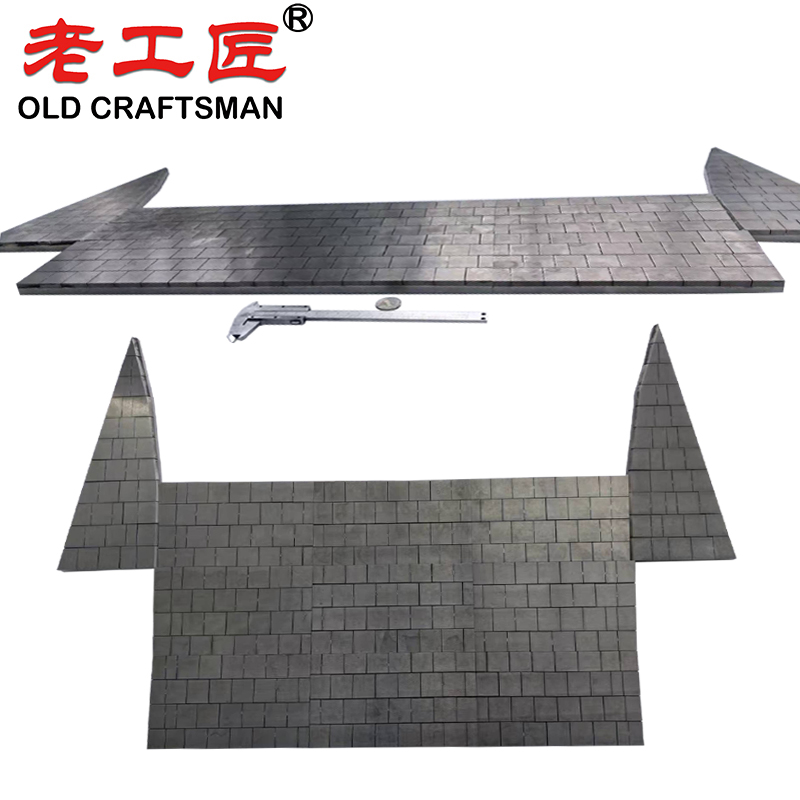

- Versatility: Used in industries like mining, oil and gas, cement production, and manufacturing, where equipment like chutes, hoppers, pipes, and crushers face intense wear.

- Customizable: Wear liners can be tailored in shape, thickness, and size to fit specific machinery or applications.

Applications:

- Mining: Lining chutes, conveyors, and crusher components to handle abrasive ores and rocks.

- Oil and Gas: Protecting drilling tools and pipelines from abrasive slurries and sand.

- Cement and Steel: Lining hoppers, mills, and mixers to withstand constant material flow.

- Recycling: Used in shredders and grinders to resist wear from processing tough materials.

Benefits:

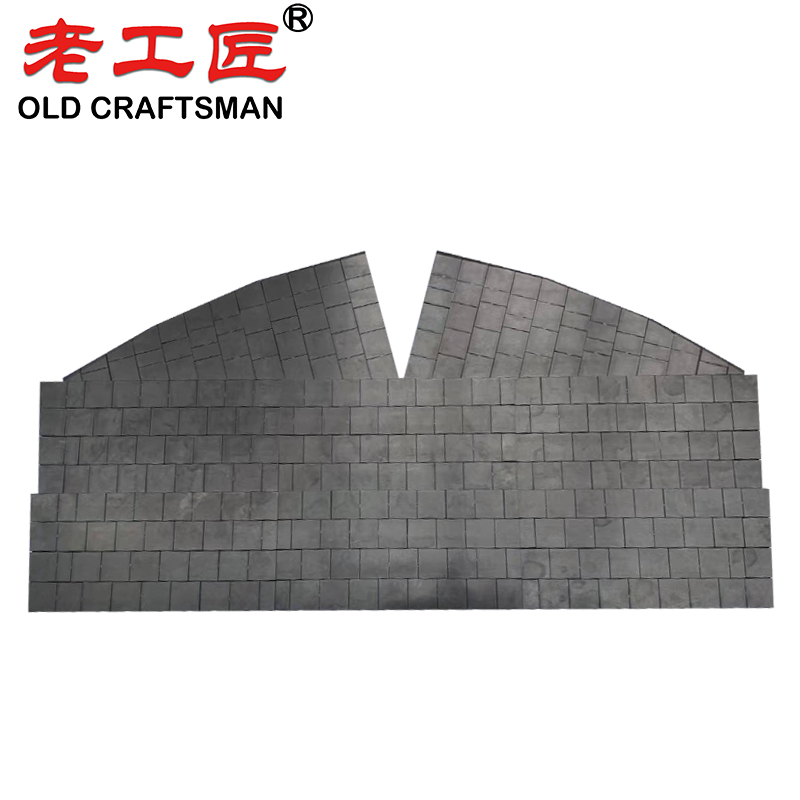

- Extends equipment lifespan, reducing maintenance costs.

- Improves operational efficiency by minimizing downtime.

- Can be applied as tiles, plates, or coatings, depending on the need.

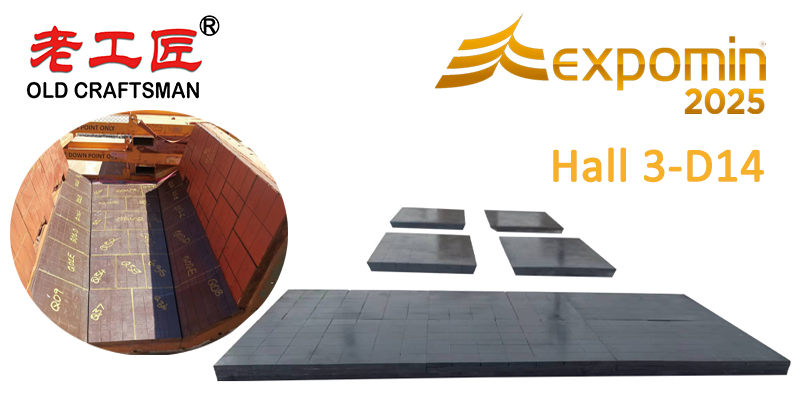

Our tungsten carbide wear liners are widely used in crushing iron ore, copper ore, magnesite, tungsten ore, granite, basalt, limestone, coal, and other ores. We look forward to welcoming you at Expomin 2025 and exploring how our tungsten carbide products can add value to your operations.

To know more about our solutions, visit www.zzcraftsman.com or contact Journey directly at 0086 15273334558. We look forward to meeting you in Santiago and exploring how our solutions can drive your success at EXPOMIN 2025!

In the demanding field of materials handling, mining tungsten carbide wear liners are widely specified for critical equipment components due to their exceptional abrasion resistance and ability to withstand high temperatures and harsh environmental conditions. These premium liners significantly reduce wear and tear on equipment exposed to highly abrasive ores and slurries, delivering extended service life and proving highly cost effective over the long term. By incorporating tungsten carbide wear liners into an asset management and maintenance strategy, operators can substantially reduce downtime, optimize routine maintenance tasks, and shift from reactive repairs to scheduled preventative maintenance. The key factors that influence the optimal maintenance schedule include the types of material being processed, intensity of abrasion, elevated temperatures, and overall operating conditions. This proactive approach not only extends equipment life but also improves operational reliability and lowers total ownership costs across a wide range of equipment types.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding