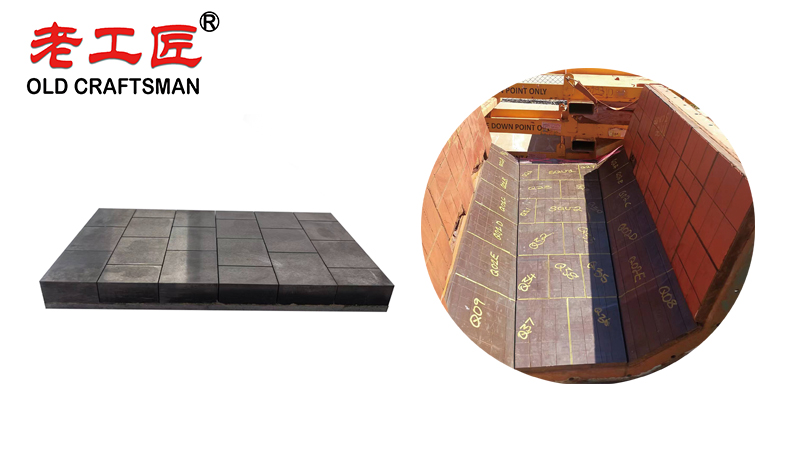

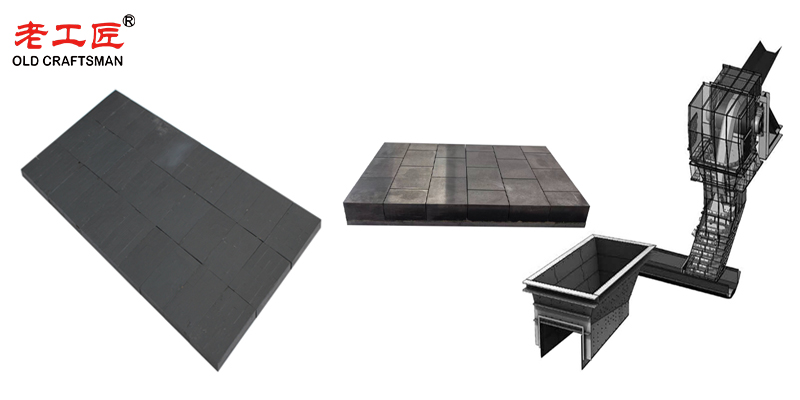

ZZ Old Craftsman Tungsten carbide chute liner plates are excellent for protecting equipment from abrasion and impact in harsh industrial environments. Here’s how to maximize their effectiveness and extend your equipment’s service life:

Proper Installation Techniques

- Precise fitting: Ensure plates are cut and shaped to match chute contours exactly

- Secure fastening: Use appropriate bolts or welding techniques to prevent movement

- Proper alignment: Avoid gaps or uneven surfaces that can create wear points

Maintenance Best Practices

- Regular inspections: Check for cracks, loose fasteners, or excessive wear every 3-6 months

- Prompt repairs: Replace individual worn plates before damage spreads

- Surface cleaning: Remove buildup of materials that could accelerate wear

Operational Considerations

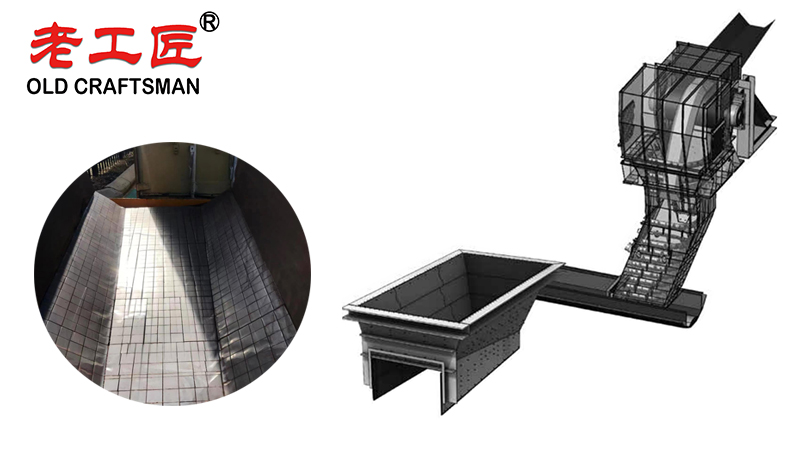

- Material flow optimization: Design chutes to ensure even material distribution across liner surface

- Impact reduction: Use rubber or polyurethane backing to absorb shock

- Angle optimization: Adjust chute angles to minimize direct impact forces

Material Selection Factors

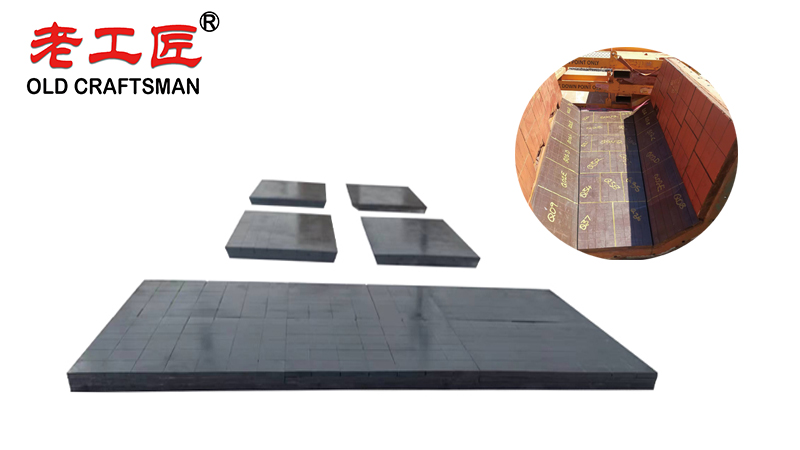

- Grade selection: Choose appropriate tungsten carbide grade (WC-Co content) for your specific abrasion/impact needs

- Plate thickness: Select thickness based on expected wear rates (typically 10-25mm)

- Reinforcement: Consider adding wear bars in high impact zones

Complementary Protection

- Transition zones: Use ceramic or polyurethane liners in areas before the carbide plates

- Overlap design: Stagger plate edges to prevent material from wearing underlying structure

- Backing material: Use resilient materials between liner and chute body for vibration dampening

Our company specializes in mining carbide chute liners and focuses on optimizing material selection and the entire manufacturing process to deliver the most wear resistant wear parts possible while achieving significant reduced cost and superior cost effectiveness. By conducting thorough material flow analysis and selecting premium yet affordable raw materials with a reliable supply chain, we ensure efficient material flow throughout the production process. Advanced material handling and transport systems, combined with real time monitoring and data driven continuous improvement practices, allow us to consistently produce high quality finished products (final products) that exceed industry standards for durability and performance. This holistic approach not only results in improved products with outstanding material properties, but also provides exceptional customer service through shorter lead times, lower total ownership costs, and reliable delivery of highly wear resistant solutions tailored to the toughest mining environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Zhuzhou Old Craftsman Precision Alloy Co., Ltd., produce carbide vacuum brazed wear parts, like wear liners, hammers and wear spare parts for crushers, mixing blades, conveyor belt scrapers, etc. for mining and crushing.

The performance is tens of times longer than the present material, these products can help users save lots of time and money on the shutdown.

If you have any wear problems, welcome to contact us for free customized design.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding