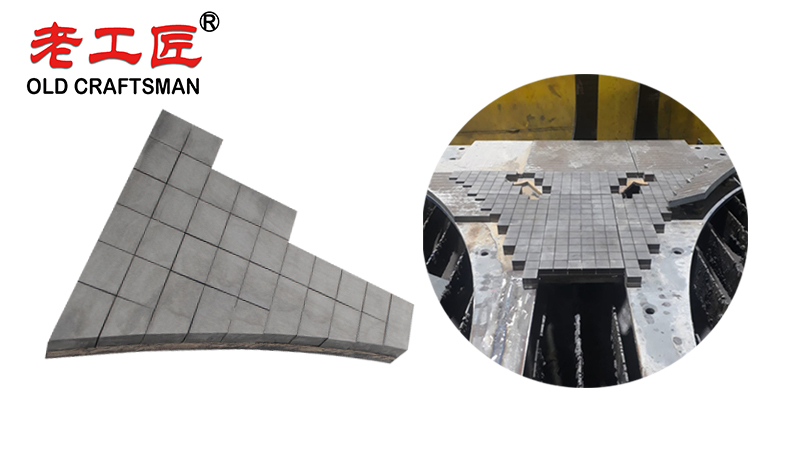

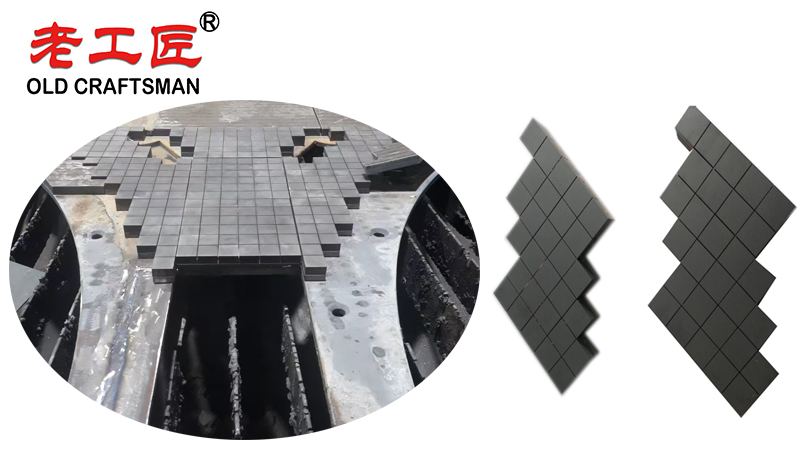

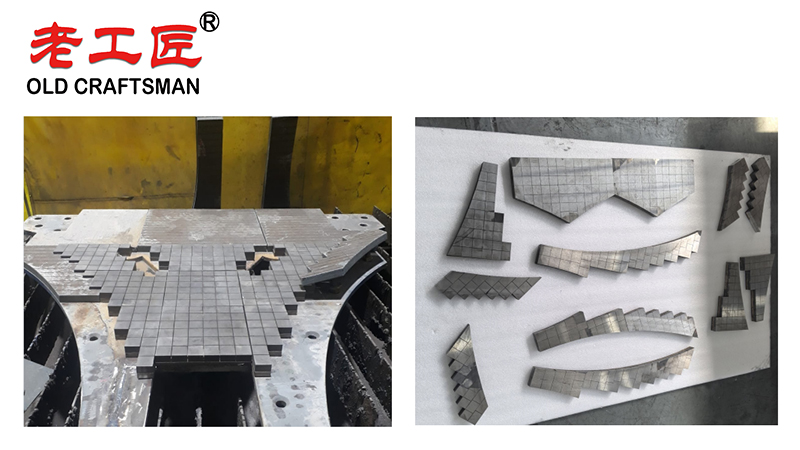

High Pressure Grinding Rolls (HPGR) cheek plates are critical wear components that protect the HPGR frame from abrasive materials during mineral processing operations. These plates experience extreme wear from the processed ore, making material selection crucial for equipment longevity.

Benefits of Tungsten Carbide Cheek Plates

Superior Wear Resistance

- Tungsten carbide offers 5-10 times longer service life compared to conventional steel plates

- Maintains dimensional stability under high pressure conditions

- Exceptional resistance to abrasive wear from hard ores

Operational Advantages

- Reduced downtime for plate replacement

- Lower maintenance costs over equipment lifetime

- Consistent grinding performance throughout wear life

- Improved process efficiency due to maintained geometry

Implementation Considerations

Installation Factors

- Proper fitting to ensure even wear distribution

- Compatibility with existing HPGR frame design

- Appropriate fastening systems for secure attachment

Economic Analysis

- Higher initial cost offset by extended service intervals

- Reduced labor costs for frequent replacements

- Lower inventory requirements for spare parts

Industry Applications

- Hard rock mining (gold, copper, iron ore)

- Diamond processing

- Cement production

- Industrial minerals processing

Maintenance Best Practices

- Regular inspection of wear patterns

- Monitoring for proper alignment

- Timely rotation or replacement to prevent frame damage

Tungsten carbide HPGR cheek plates represent a significant advancement in wear protection technology, offering mining and processing operations an effective solution for extending equipment life while reducing total operating costs.

By following these maintenance practices, HPGR tungsten carbide cheek plates can achieve longer service life, reduced downtime, and lower operational costs. Regular monitoring, proper operation, and timely repairs are key to maximizing their durability.

HPGR (High Pressure Grinding Rolls) carbide cheek plates and carbide wear parts are manufactured from premium tungsten carbide wear resistant materials to provide exceptional abrasion resistance and extended service life in extremely demanding mineral processing environments. Under high temperature and intense mechanical action, traditional tool steel or stainless steel wear plates suffer rapid wear and tear through multiple types of wear mechanisms, including abrasive wear, adhesive wear, and surface fatigue. The significantly lower coefficient of friction of tungsten carbide on solid surfaces, combined with its outstanding hardness and toughness, dramatically reduces material loss even when processing highly abrasive ores over a prolonged period of time. By installing tungsten carbide cheek plates and other wear resistant materials in critical zones, operators can substantially minimize downtime, lower maintenance costs, and resist material degradation in the harshest wear applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding