Tungsten carbide chute wear liners are essential for industries dealing with abrasive materials, such as mining, cement, and bulk material handling. ZZ OLDCRAFTSMAN is a reputable manufacturer known for producing high quality wear resistant liners. Here’s a comprehensive guide to help you make an informed purchase.

1. Understand Your Application Needs

Before purchasing, assess:

- Material Type: What kind of abrasive material will the liner face (e.g., coal, ore, sand)?

- Impact & Abrasion Levels: High pact applications need thicker or reinforced liners.

- Operating Environment: Consider temperature, moisture, and chemical exposure.

2. Key Features of ZZ OLDCRAFTSMAN’s Tungsten Carbide Liners

- Extreme Wear Resistance: Tungsten carbide is one of the hardest materials, offering superior durability.

- Impact Resistance: Designed to withstand heavy impacts without cracking.

- Corrosion Resistance: Ideal for harsh environments.

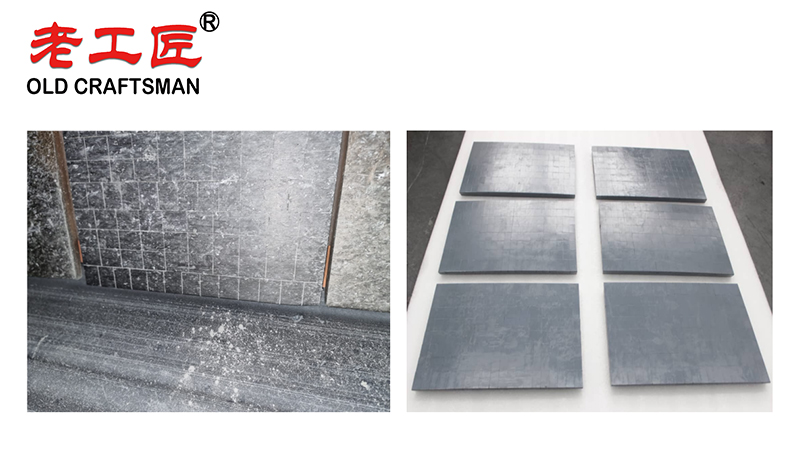

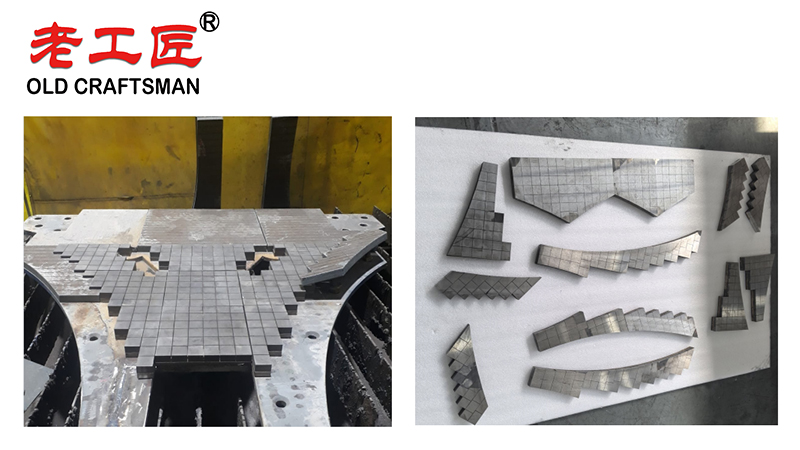

- Customizable Shapes & Sizes: Available in tiles, plates, or custom-molded designs.

- Easy Installation: Can be bolted or welded into place.

3. Types of Wear Liners Available

- Tungsten Carbide Tiles: Small, replaceable inserts for high-wear areas.

- Full Liners: Large plates covering entire chute surfaces.

- Composite Liners: Combine tungsten carbide with steel backing for added strength.

4. How to Choose the Right Liner

| Factor | Consideration |

|---|---|

| Thickness | Thicker liners (10-25mm) for high-impact zones. |

| Shape | Tiles for localized wear, full liners for uniform protection. |

| Attachment Method | Bolted for easy replacement, welded for permanent solutions. |

| Budget | Higher upfront cost but longer lifespan reduces downtime. |

5. Installation & Maintenance Tips

- Proper Alignment: Ensure liners are flush to prevent material buildup.

- Regular Inspections: Check for wear and replace damaged sections promptly.

- Use Compatible Hardware: High strength bolts/welds to secure liners.

6. Where to Buy

- Direct from ZZ OLDCRAFTSMAN: Visit our official website or contact sales.

- Authorized Distributors: Check for certified resellers in your region.

- Online Marketplaces: Verify seller authenticity before purchasing.

7. Cost Considerations

- Price Range: Varies by size, thickness, and customization.

- ROI: Higher initial cost but extended service life reduces replacement frequency.

8. Warranty & Support

- Check if ZZ OLDCRAFTSMAN offers a warranty (typically 6 months to 2 years).

- Ensure after sales support for installation guidance.

Final Recommendation

For heavy-duty abrasion resistance, ZZ OLDCRAFTSMAN’s tungsten carbide liners are an excellent choice. Evaluate your specific needs, compare options, and consult with our technical team for the best solution.

In industrial applications, mining chute liners require exceptional abrasion resistance to withstand abrasive wear from raw materials in material handling systems like conveyor belts. Silicon carbide and tungsten carbide are wear resistant materials valued for their high strength and superior mechanical properties, making them ideal for long term durability under high temperatures. These materials effectively resist material degradation, outperforming stainless steel in harsh environments. Their low coefficient of friction reduces wear on cutting tooling and ensures efficient material flow. While bonded abrasives can be used to remove material during maintenance, silicon carbide and tungsten carbide liners are cost effective solutions, balancing initial investment with extended service life in demanding mining operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear plates, Liners for HPGR Feed Chute and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding