High Pressure Grinding Rolls (HPGR) are an advanced comminution technology that has gained significant traction in the mining industry due to their energy efficiency, ability to handle hard and abrasive ores, and potential for reducing downstream processing costs.

Key Applications in Mining

1. Comminution (Crushing & Grinding)

- Primary/Secondary Crushing: HPGRs can replace traditional jaw or cone crushers, particularly for hard ores, providing a finer product with micro-cracks that improve downstream grinding efficiency.

- Tertiary Crushing: Used before ball mills to reduce feed size, enhancing grinding performance and lowering energy consumption.

- Grinding Circuits: HPGRs are increasingly used in place of or in combination with SAG (Semi Autogenous Grinding) and ball mills, reducing energy consumption by 20-50%.

2. Diamond Mining

- HPGRs are widely used in diamond processing to minimize diamond breakage (due to their compressive action rather than impact) while efficiently liberating diamonds from kimberlite ore.

3. Iron Ore Processing

- Used for pellet feed preparation, HPGRs improve particle size distribution and reduce energy consumption compared to conventional crushing and grinding.

- Beneficiation of hematite and magnetite ores by generating micro-cracks, improving downstream liberation.

4. Gold & Copper Ore Processing

- Gold Ores: HPGRs enhance heap leach recovery by producing a more porous, fractured product, improving cyanide percolation.

- Copper Ores: Used in SABC (SAG-Ball-Crusher) circuits to optimize grinding efficiency and reduce energy costs.

5. Cement & Industrial Minerals

- HPGRs are used for limestone, clinker, and slag grinding, offering energy savings and improved particle size control.

Advantages of HPGR in Mining

✔ Energy Efficiency: Up to 30-50% lower energy consumption compared to conventional grinding.

✔ Reduced Operating Costs: Lower wear rates and maintenance requirements than SAG/ball mills.

✔ Improved Liberation & Leachability: Micro-cracks enhance mineral liberation and leaching efficiency.

✔ Scalability: Suitable for large scale mining operations.

Challenges & Considerations

- High Capital Cost: Initial investment can be significant.

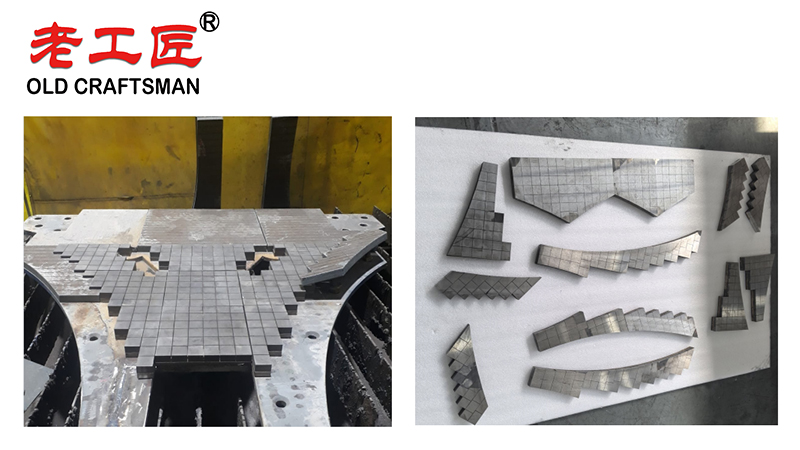

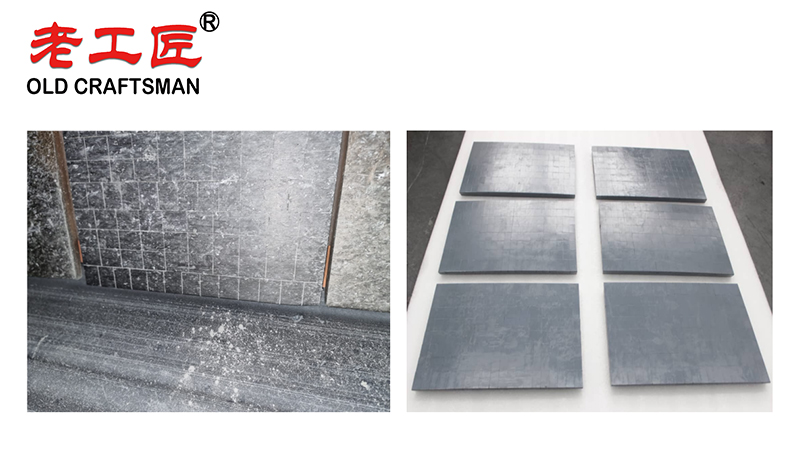

- Wear on Rolls: Abrasive ores can cause roll surface wear, requiring advanced materials like tungsten carbide studs.

- Feed Size Limitations: Requires consistent feed size for optimal performance.

In many places, fossil fuels like natural gas are still the main sources of electricity. Rising energy costs are pushing industries to reduce energy use in their large processes. High pressure grinding rolls (HPGR), equipped with durable carbide cheek plates, offer a cost effective alternative to traditional ball mills by delivering a more uniform particle size distribution and introducing micro cracks that enhance downstream efficiency. This technology significantly lowers energy requirements often achieving 20-50% savings compared to ball mill circuits leading to long term cost savings, the ability to save money on operational expenses, and a step toward more sustainable energy systems in mining and mineral processing.

Installing HPGR cheek plates in mining operations significantly improves product quality by producing smaller particles with less energy consumption compared to traditional crushers. In the long term, homeowners can achieve similar cost effective principles by focusing on reducing the amount of energy used for heating and cooling, water heating, and overall household energy bills. Simple upgrades like high efficiency water heaters, sealing air leaks, turning off appliances via a power strip, and running the air conditioner only when needed can lead to substantial cost savings. For even greater long term benefits, switching to renewable energy sources and using just a small amount of hot water (whether for washing dishes, showering, or preparing breast milk or formula) can dramatically lower energy costs while maintaining comfort and convenience.

Conclusion

HPGR technology is transforming mineral processing by offering energy efficient, cost ffective comminution solutions. Its adoption is growing in diamond, iron ore, gold, and copper operations, with ongoing advancements improving durability and efficiency.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding