High Pressure Grinding Rolls (HPGRs) are increasingly adopted in large scale mining projects due to their ability to reduce energy costs significantly compared to traditional grinding methods like SAG (Semi-Autogenous Grinding) and ball mills. Here’s how HPGRs achieve energy savings:

1. Energy Efficiency Through Inter Particle Comminution

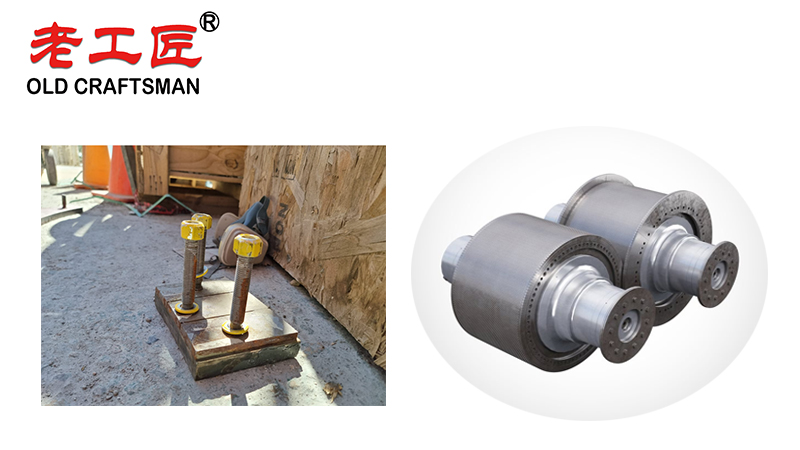

- HPGRs compress the ore bed between two counter rotating rolls, promoting inter particle breakage rather than impact or attrition-based grinding.

- This method is more energy efficient because it minimizes over grinding and reduces energy waste in generating fine particles.

- Studies show HPGRs can reduce energy consumption by 20–50% compared to conventional grinding circuits.

2. Reduced Work Index (Wi) in Downstream Processes

- HPGRs produce micro-cracks in ore particles, making them easier to grind in subsequent ball milling stages (if required).

- This pre-weakening effect lowers the Bond Work Index, reducing energy needs in downstream grinding.

3. Selective Grinding & Higher Liberation Efficiency

- HPGRs generate a more uniform particle size distribution with fewer ultra fines, improving mineral liberation.

- Better liberation reduces the need for excessive regrinding, saving energy.

4. Lower Media Consumption & Operating Costs

- Unlike ball mills, HPGRs do not require grinding media (steel balls), eliminating associated costs.

- Reduced wear and maintenance compared to tumbling mills further cut operational expenses.

5. Integration with Dry Processing & Pre-Concentration

- HPGRs can operate in dry grinding circuits, eliminating water use and reducing slurry pumping costs.

- When combined with sensor based ore sorting, HPGRs allow early waste rejection, reducing the tonnage fed to energy-intensive grinding stages.

6. Scalability & Hybrid Circuits

- HPGRs can be used in hybrid circuits (e.g., HPGR + ball mill or stirred mill), optimizing energy use across different ore types.

- For hard ores, HPGRs are particularly effective, while softer ores may still benefit from partial HPGR use.

Case Study: Energy Savings in Copper/Gold Mining

- Newmont’s Boddington mine reported 15–20% energy savings after integrating HPGRs.

- Freeport-McMoRan’s Cerro Verde operation saw a 20% reduction in energy use with HPGRs compared to SAG mills.

Conclusion

By adopting HPGR technology, mining operations can achieve:

✔ Lower kWh/ton energy consumption

✔ Reduced downstream grinding costs

✔ Lower water and media usage

✔ Higher throughput with finer liberation

For large scale projects, HPGRs offer a sustainable, cost effective alternative to traditional grinding, aligning with global mining trends toward energy efficiency and decarbonization.

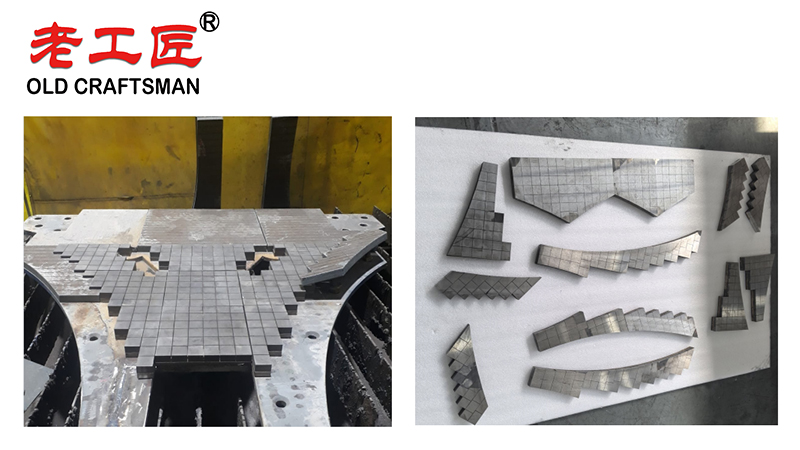

The long-term, large scale adoption of High Pressure Grinding Rolls (HPGR) with wear resistant cheek plates in mineral processing operations, particularly for critical minerals essential to electric vehicles, has demonstrated significant environmental and economic advantages over traditional crushing methods. By substantially reducing energy consumption (often by 20–40 % compared to conventional crushers), HPGR technology lowers energy bills and decreases reliance on fossil fuels and natural gas for power generation, while producing less waste material and requiring fewer raw materials overall. Major mining companies such as Rio Tinto have successfully implemented HPGR in large open-pit operations, achieving not only lower operating costs and more cost effective supply chains, but also a markedly improved life cycle environmental impact through reduced greenhouse gas emissions, lower water usage, and the potential for drier tailings storage. These combined benefits translate directly into cost savings across the electric vehicle battery value chain, making sustainable critical mineral production more economically viable without compromising heating and cooling needs in processing plants.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding