Conveyor tungsten carbide secondary cleaners are highly effective in reducing material carryback a common issue in bulk material handling where residual material sticks to the conveyor belt and falls off at unintended locations. Here’s how they work:

1. Enhanced Cleaning Efficiency

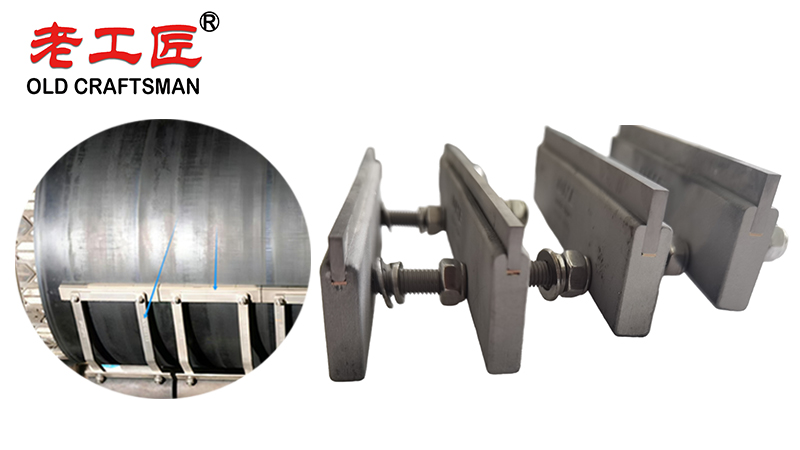

- Tungsten Carbide Blades: These cleaners feature ultra-durable tungsten carbide scraping blades that aggressively remove fine and sticky material from the belt surface.

- Precision Edge Design: The sharp, rigid edges ensure thorough cleaning, even with tough residues like clay, coal, or wet minerals.

2. Reduced Belt Wear

- Unlike softer materials, tungsten carbide maintains its sharpness longer, reducing friction-induced belt wear while still cleaning effectively.

- Minimizes the need for excessive belt pressure, prolonging belt life.

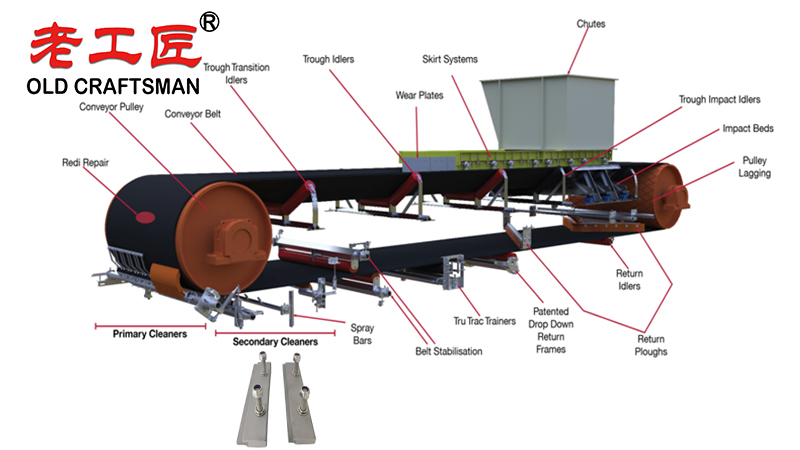

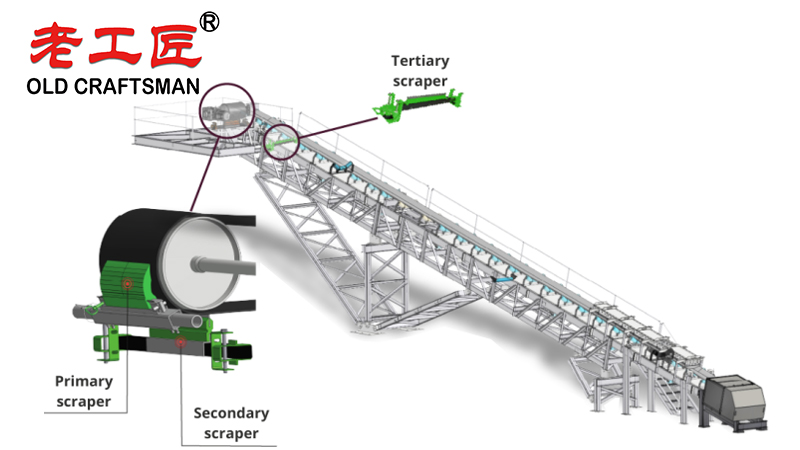

3. Secondary Cleaning Role

- Positioned after primary cleaners, they target residual particles that escape initial cleaning.

- Work in tandem with other cleaners (e.g., polyurethane or steel blades) for a multi-stage cleaning approach.

4. Adaptability to Belt Conditions

- Adjustable tension systems allow optimal blade-to-belt contact, compensating for belt wear or misalignment.

- Effective on both wet and dry materials, preventing buildup that leads to carryback.

5. Lower Maintenance & Cost Savings

- Tungsten carbide’s extreme hardness means longer service life, reducing replacement frequency.

- Less carryback means less material waste, cleaner workspaces, and reduced cleanup costs.

6. Environmental & Safety Benefits

- Reduces spillage, preventing slip hazards and dust pollution.

- Improves conveyor efficiency, lowering energy consumption from belt drag caused by carryback.

A high-performing conveyor belt scraper specifically designed for bulk materials handling is a critical component in any efficient conveyor system. Engineered with advanced wear resistance materials often incorporating high strength stainless steel and specialized polymers these scrapers deliver outstanding mechanical properties, including superior abrasive wear resistance and reliable performance even under high temperature conditions.

The key to maximum cleaning efficiency lies in achieving an optimal coefficient of friction between the scraper blade and the belt surface, ensuring deep cleaning of sticky, fine, or abrasive residues without damaging the belt. This thorough material removal significantly improves material flow, prevents carryback, reduces spillage, and minimizes the need for manual cleaning or wide range purpose cleaners.

By maintaining a consistently clean belt, these high performing scrapers not only extend belt and component lifespan but also boost overall productivity and operational cost effectiveness in demanding mining and bulk material processing environments. Investing in a premium, mechanically engineered scraper ultimately delivers lower maintenance costs, reduced downtime, and superior long-term performance across the entire conveyor system.

Conclusion

By combining durability, precision, and aggressive cleaning action, tungsten carbide secondary cleaners significantly minimize carryback, enhancing conveyor performance, reducing downtime, and cutting operational costs.

Tungsten carbide secondary cleaners are the optimal choice for mining conveyor systems due to their unmatched wear resistance, efficiency in material removal, and long-term cost savings. They help maintain belt longevity, reduce maintenance, and improve operational efficiency in abrasive mining environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding