Executive Summary

HPGR (High Pressure Grinding Rolls) carbide cheek plates are critical, wear resistant components that contain the feed material between the two rolls. By preventing sideways escape of material, they force it through the nip (the gap between the rolls), creating a compressed particle bed. This containment is fundamental to the HPGR’s energy efficient principle. The extreme hardness and durability of carbide ensure this process remains stable and efficient over long operational periods, minimizing energy waste from wear related issues and downtime.

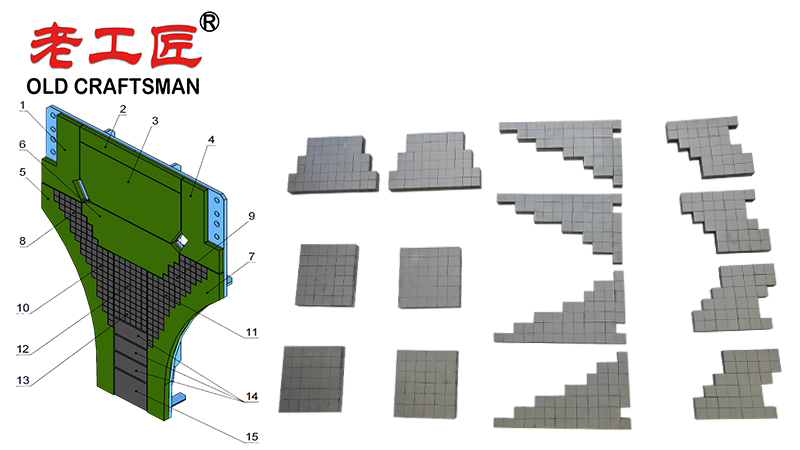

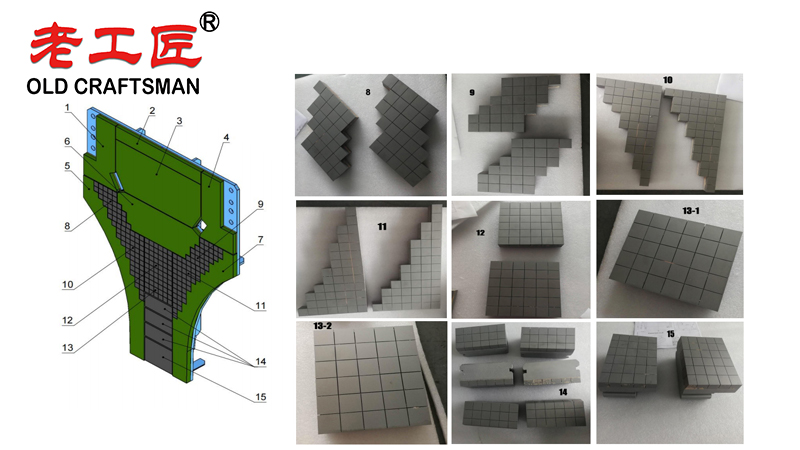

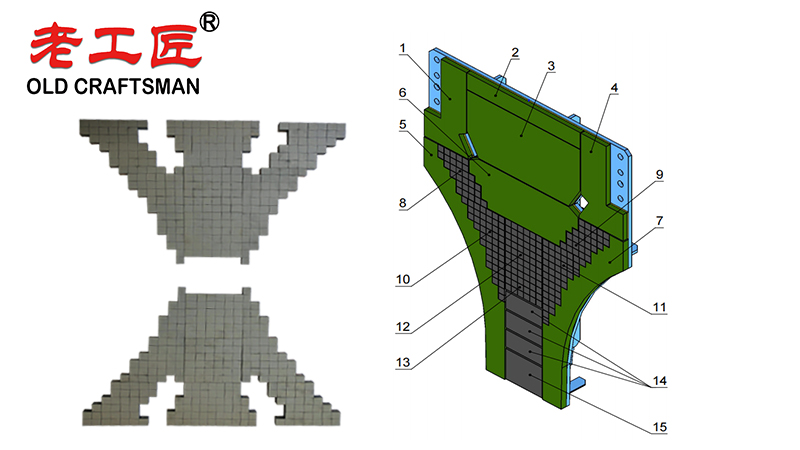

The Role of Cheek Plates in an HPGR

First, it’s essential to understand what cheek plates do:

- Location: They are fixed on either side of the rolls, creating a “wall” that forms a grinding chamber with the two rolls.

- Primary Function: To contain the feed material and direct it into the nip zone, the narrowest point between the counter-rotating rolls. Without cheek plates, material would simply squeeze out sideways instead of being compressed.

The entire energy efficient grinding process of an HPGR relies on this containment to work correctly.

How They Directly Contribute to Energy Efficiency

1. Enabling the Particle Bed Comminution Principle

This is the most significant contribution. HPGRs don’t crush individual rocks like a jaw crusher; they compress a bed of particles.

- The Process: The cheek plates contain a large volume of material, which is fed into the rolls. The particles are pressed against each other under immense pressure (e.g., 50-500 MPa). This causes inter-particle comminution particles break each other, which is far more efficient than breaking them against a steel surface.

- Energy Efficiency Link: Inter particle breakage requires less energy than single particle breakage for the same size reduction. The cheek plates are the enablers of this entire mechanism. Worn or inefficient cheek plates would allow material to bypass this process, high temperatures drastically reducing efficiency and reducing enegy.

2. Maintaining Optimal Operating Pressure and Flow

Consistent and stable operation is key to energy efficiency.

- Stable Feed Density: The cheek plates help maintain a choke-fed condition (a fully packed grinding chamber). This ensures a consistent and dense particle bed enters the nip, allowing the HPGR to generate and maintain the required high pressure effectively.

- Preventing Bypass: If cheek plates wear down, gaps open up between them and the roll edges. Material escapes sideways (“edge effect”) without being compressed. The machine must work harder (consuming more energy) to achieve the same throughput and product size, or more likely, performance will drop. Robust carbide plates maintain a tight seal for thousands of hours.

3. Reducing System Energy Consumption via Circuit Design

HPGRs are often used in place of or before traditional SAG/Ball mills. This is where the largest energy savings are realized.

- Pre-weakening Effect: The micro cracks generated inside ore particles by the HPGR mean that downstream ball mills can grind the material much more easily.

- Higher Throughput: A well functioning HPGR with reliable cheek plates can process vast amounts of ore, reducing the grinding work required by the more energy intensive ball mills.

- Overall Plant Energy Saving: By enabling this efficient pre-treatment, HPGRs can reduce overall grinding circuit energy consumption by 20-35%. The cheek plates are a cornerstone of the HPGR’s reliability, making this circuit design feasible.

4. Maximizing Uptime and Minimizing Downtime (Indirect Energy Savings)

Energy is wasted every time a machine stops and starts and during non-productive maintenance periods.

- Superior Wear Resistance: Tungsten carbide is one of the hardest materials available for this application. Carbide cheek plates last 3 to 10 times longer than steel or white iron plates.

- Less Frequent Changes: Fewer changes mean:

- Less downtime for maintenance, and saving money.

- More continuous, efficient operation.

- Reduced renewable energy, natural gas consumed by maintenance equipment, and improve energy efficiency(e.g., cranes, tools).

- Lower risk of unplanned stoppages due to catastrophic cheek plate failure.

5. Improving Product Quality for Downstream Processes

An efficient grind leads to energy savings later in the process.

- More Fines Generation: The efficient particle-bed compression creates more fine material in the product.

- Liberation: This can lead to better mineral liberation at a coarser size, potentially reducing energy in downstream processes like hydrocyclones or flotation cells, cost savings.

Comparison: Carbide vs. Traditional Materials

| Feature | Tungsten Carbide Cheek Plates | Traditional Manganese / White Iron Plates | Impact on Energy Efficiency |

|---|---|---|---|

| Hardness | Extremely High (~1500 HV) | Lower (~700 HV for white iron) | High: Maintains sealing integrity longer, preventing energy wasting bypass. |

| Wear Life | Very Long (6-12+ months) | Short (1-4 months) | High: Drastically reduces downtime and maintenance energy costs. |

| Cost | High Initial Investment | Lower Initial Investment | Long term saving: Lower cost per ton processed over lifetime. |

| Performance | Consistent pressure and output | Gradual performance degradation | High: Provides stable, energy optimal operation throughout its life. |

To achieve maximum long term cost savings and reduce electricity consumption, one of the most overlooked yet highly effective upgrades in heavy industry is the use of High Pressure Grinding Rolls (HPGR) with advanced cheek plates. These specially designed wear resistant cheek plates significantly improve energy efficiency by minimizing energy loss through sidewall friction and material leakage, allowing the HPGR to transfer more power directly into particle breakage. Compared to traditional crushing systems, modern HPGR equipped with high performance cheek plates can reduce specific energy consumption by 10–30 %, delivering substantial reductions in energy bills over the equipment’s lifetime. Just as switching to ENERGY STAR certified LED light bulbs or installing a heat pump water heater yields dramatic savings in households through efficient technologies and energy conservation, adopting optimized HPGR cheek plates represents the industrial equivalent: a proven, long term efficiency product that cuts energy costs, lowers overall electricity consumption, and delivers rapid payback in high-tonnage mineral processing operations.

Conclusion

HPGR carbide cheek plates are not just passive wear parts; they are active enablers of energy efficient technology. Their primary role of containing the particle bed is the foundational principle that allows HPGRs to perform their low energy comminution. By ensuring this process remains stable, consistent, and reliable over extended periods thanks to their exceptional wear resistance, carbide cheek plates directly contribute to significant reductions in energy consumption per ton of ore processed, making mineral processing more sustainable and cost-effective.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding