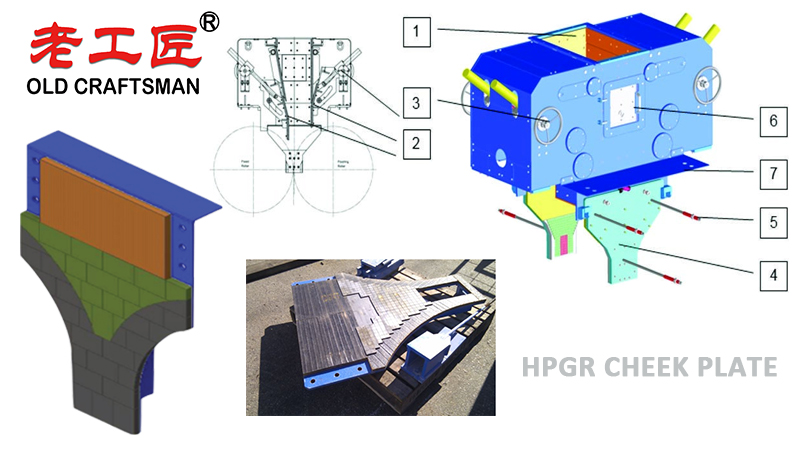

High-Pressure Grinding Rolls (HPGRs) are widely used in mining for energy efficient comminution, and tungsten carbide cheek plates play a crucial role in enhancing their performance while reducing operational costs. Here’s how they contribute to cost savings:

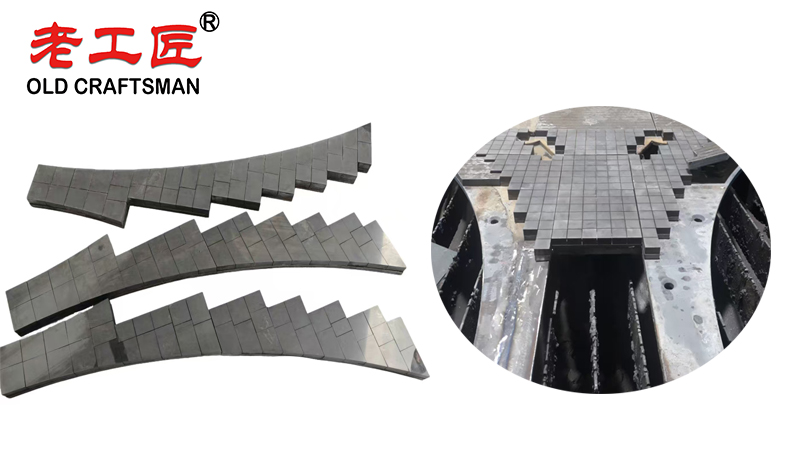

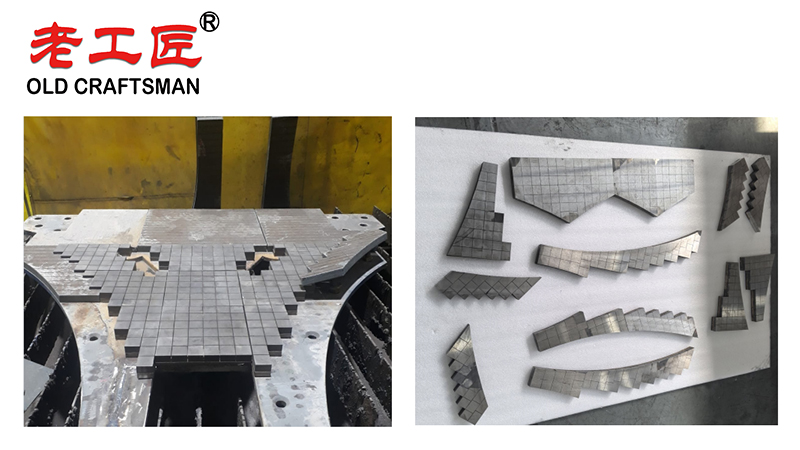

1. Extended Wear Life & Reduced Replacement Frequency

- Tungsten carbide is extremely hard and wear resistant, high pressure far outperforming traditional materials like manganese steel.

- Cheek plates made from tungsten carbide last 3-5 times longer, reducing downtime for replacements.

- Fewer change-outs mean lower labor costs and less machine downtime, improving overall productivity.

2. Improved Grinding Efficiency & Energy Savings

- The hardness of tungsten carbide maintains consistent grinding gaps in the HPGR, ensuring optimal particle size reduction.

- Efficient grinding reduces recirculation loads, lowering energy consumption per ton of processed ore.

- Studies show HPGRs with tungsten carbide components can reduce energy use by 15-30% compared to conventional crushers.

3. Lower Maintenance & Downtime Costs

- Unlike softer materials that degrade quickly, tungsten carbide maintains structural integrity under high pressure.

- Reduced wear means fewer unplanned shutdowns for cheek plate replacements.

- Maintenance intervals are extended, cutting labor and equipment costs over time.

4. Enhanced Throughput & Operational Consistency

- Worn cheek plates wear and tear can cause uneven grinding, leading to inefficient processing and higher operational costs.

- Tungsten carbide’s durability ensures stable performance, maximizing throughput and reducing bottlenecks.

5. Reduced Total Cost of Ownership (TCO)

- While tungsten carbide cheek plates have a higher upfront cost, their longevity and efficiency lead to lower total costs over the equipment’s lifespan.

- Reduced energy, maintenance and replacement expenses contribute to significant long-term savings.

Conclusion

By minimizing wear, improving energy efficiency, and reducing maintenance needs, tungsten carbide cheek plates in HPGRs help mining operations cut operational costs while maintaining high productivity. Their durability and performance make them a cost effective investment for modern mineral processing.

HPGR cheek plates deliver significant long-term cost savings and prove highly cost effective in demanding grinding applications. Thanks to their advanced wear-resistant design, these premium wear parts dramatically extend service life, reducing operating costs and minimizing expensive downtime and frequent replacements. By optimizing pressure distribution and improving overall efficiency, HPGR technology with high quality cheek plates contributes to substantial energy savings, lowering energy bills even under high-temperature conditions. This reduced energy consumption, combined with lower consumption of raw materials and spare parts, helps cut total operating costs while strengthening supply chain resilience. In industries such as mining, cement, and oil and gas, choosing durable, wear resistant HPGR cheek plates not only saves you money in maintenance and energy, but also reduces costs related to heating and cooling systems, delivering superior performance and outstanding return on investment over the entire equipment lifecycle.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding