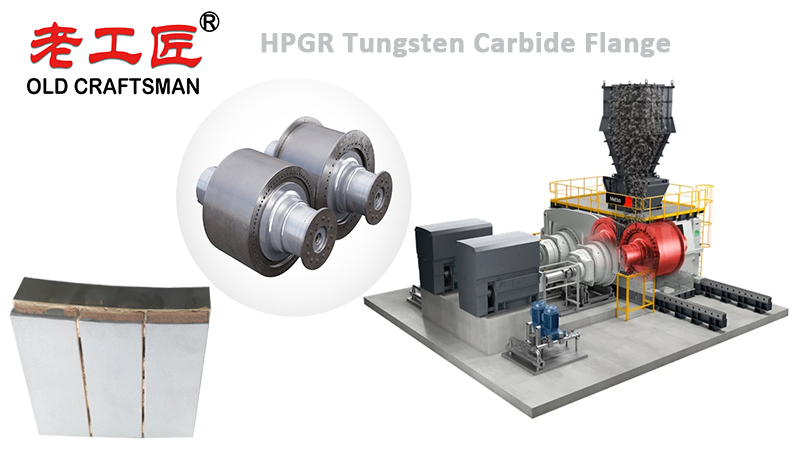

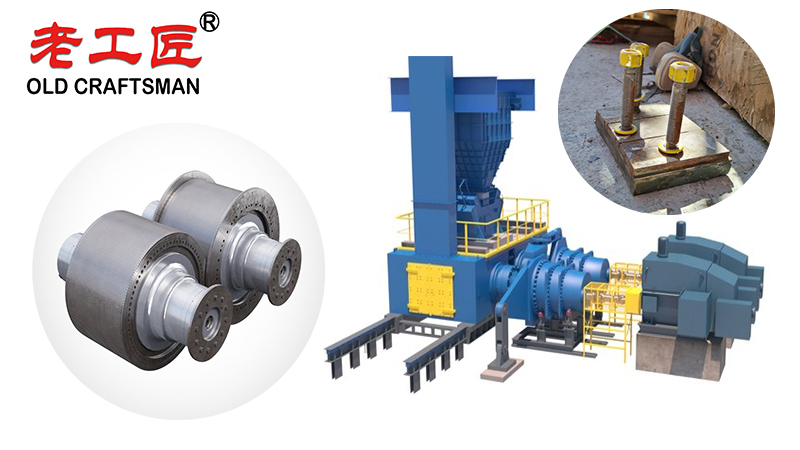

Mining High Pressure Grinding Roller (HPGR) tungsten carbide flanges significantly reduce maintenance costs through several key mechanisms:

1. Exceptional Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV 1500-2000), far outperforming traditional steel alloys.

- Reduces flange wear caused by abrasive ore particles, extending service life by 3-5 times compared to steel flanges.

- Minimizes frequent replacements, lowering downtime and labor costs.

2. Reduced Downtime & Increased Productivity

- Longer operational lifespan means fewer shutdowns for flange replacements.

- HPGR systems with tungsten carbide flanges can operate continuously for thousands of hours without maintenance interruptions.

3. Lower Replacement & Labor Costs

- Fewer changeouts reduce the need for spare parts and maintenance crews.

- Eliminates frequent welding or machining repairs required for steel flanges.

4. Improved Grinding Efficiency

- Maintains consistent geometry over time, ensuring stable HPGR performance.

- Prevents uneven wear that can lead to inefficient grinding and higher energy consumption.

5. Corrosion & Impact Resistance

- Resists chemical corrosion from wet ore processing environments.

- High fracture toughness reduces chipping or cracking under high pressure loads.

Cost Savings Example:

- A mining operation switching from steel to tungsten carbide flanges may see:

- 50-70% reduction in flange-related maintenance costs.

- 30% longer intervals between replacements.

- Higher throughput due to fewer operational stoppages.

The implementation of High Pressure Grinding Rolls (HPGR) with specially designed HPGR flanges has proven to deliver significant cost savings compared to traditional stainless steel ball mills, particularly in applications involving high temperatures and severe abrasive wear. Thanks to their ability to operate reliably at high speeds and across a wide range of operating parameters and operating conditions, HPGR systems provide high strength and exceptional durability of wear parts. This results in substantially reduced maintenance requirements and lower maintenance costs over the long term. The superior grinding process achieved with roller mills produces a material with improved surface roughness and better downstream performance, leading to increased productivity, optimal performance, and high-quality final products while minimizing downtime and replacement frequency of critical components.

Conclusion

By investing in tungsten carbide HPGR flanges, mining operations achieve long-term cost savings through reduced wear, fewer maintenance cycles, and improved grinding efficiency. This makes them a superior choice for high abrasion mineral processing applications.

For HPGR flanges, tungsten carbide is unmatched in durability, wear resistance, and operational efficiency, making it the preferred choice in modern mining operations. Its ability to withstand extreme pressure and abrasion ensures longer lifespan and lower total cost of ownership compared to steel or ceramic alternatives.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding