Choosing durable tungsten carbide blades for intensive mixers is a critical decision that directly impacts mixing efficiency, product quality, maintenance costs, and overall operational profitability. Here is a comprehensive guide to making the right choice.

Executive Summary: The Key Factors

Durability isn’t just about hardness. It’s a balance of several properties tailored to your specific application. The most durable blade for your process will excel in:

- Wear Resistance: Resistance to abrasion from hard materials.

- Fracture Toughness: Resistance to chipping and catastrophic breakage.

- Corrosion Resistance: Resistance to chemical attack from ingredients.

- Geometry & Design: Optimized for the material flow and stress distribution.

- Quality of Manufacture: Absence of internal flaws and precise fabrication.

Step-by-Step Guide to Selection

1. Understand Your Application (The Most Important Step)

The “best” blade is meaningless if it’s wrong for your mix. Define these parameters:

- Materials Being Mixed: List all ingredients and their percentages.

- Abrasive Fillers: Carbon black, silica, quartz, minerals, clays. These are the primary wear agents.

- Chemical Nature: Oils, plasticizers, acids, solvents. These can corrode the binder.

- Bulk Density: Heavy mixes impart higher forces on the blades.

- Temperature: Mixing generates heat; some chemicals are more aggressive when hot.

- Mixer Type and Size: Know your mixer model (e.g., Banbury®, Intermix, etc.) and chamber size. The blade design must be compatible.

- Process Parameters:

- Rotor Speed: Higher speeds increase wear and impact forces.

- Fill Factor: Overloading increases stress.

- Cycle Time: Longer cycles mean more total wear.

- Discharge Temperature: A key indicator of process severity.

2. Deciphering Tungsten Carbide Grades: The Cobalt Binder %

Tungsten Carbide (WC) is a hard ceramic particle. It’s held together by a metallic binder, almost always Cobalt (Co). The ratio of WC to Co is the primary determinant of properties.

| Cobalt Content | Hardness (HRA) | Wear Resistance | Fracture Toughness | Best For |

|---|---|---|---|---|

| Low (3-6%) | Very High (90-94+) | Excellent | Lower (More Brittle) | Highly abrasive mixes with no impact risk (e.g., fine minerals, steady-state mixing). |

| Medium (7-10%) | High (89-92) | Very Good | Good (Balanced) | The most common choice. Offers the best balance for mixes with moderate abrasives and some potential for shock (e.g., most rubber compounds). |

| High (12-16%) | Medium (85-88) | Good | Excellent | Mixes with high impact risk, large, hard nuggets, or potential for tramp metal. Sacrifices some wear resistance for superior shock absorption. |

Advanced Grades:

- Nickel-Chromium Binder: Used instead of cobalt when corrosion resistance is paramount (e.g., for mixing halogenated polymers, strong acids, or salt-rich compounds).

- Fine-Grained Carbides: Offer superior hardness and wear resistance without sacrificing too much toughness. A premium option for extreme abrasion.

Selection Rule: Choose the hardest grade that can survive the mechanical and chemical shocks of your process without fracturing. When in doubt, a medium (e.g., 9% Co) grade is a safe and durable starting point.

3. Blade Geometry and Design

The shape isn’t just for moving material; it’s crucial for durability.

- Leading Edge Geometry: A sharper edge cuts more efficiently but is prone to chipping. A more radiused or chamfered edge is far more durable against impact. Discuss with your supplier the optimal edge preparation for your mix.

- Wing Design: The wings must be designed to handle the specific shear and scraping forces without flexing or creating high stress points that can initiate cracks.

- Quality of Brazing: The carbide tips are brazed onto a steel shaft. A poor braze joint is a common failure point. It must be full, continuous, and free of voids or oxides to withstand immense torque and heat.

4. Manufacturing Quality and Inspection

A blade with perfect chemistry will fail if it’s poorly made.

- Raw Material Purity: High quality, consistent WC and Co powders are essential.

- Sintering Process: The high temperature process that fuses the carbide must be perfectly controlled to avoid defects like porosity, cobalt pools, or eta-phase (a brittle compound).

- Non-Destructive Testing (NDT): Reputable manufacturers use:

- Dye Penetrant Inspection (DPI): To detect surface cracks.

- X-Ray Inspection: To look for internal voids and flaws in the braze joint.

- Ultrasonic Testing: To check for delaminations or internal cracks.

- Always ask your supplier about their quality control and inspection protocols.

5. Supplier Expertise

Choose a supplier that acts as a partner, not just a vendor.

- Application Knowledge: Do they understand intensive mixing and your industry?

- Technical Support: Can they help you analyze failed blades and recommend improvements?

- Customization: Will they tailor the grade, geometry, and edge prep for your needs?

- Reputation & References: Ask for case studies or contact existing customers.

Practical Checklist for Procurement

When requesting a quote or evaluating a new blade supplier, ask these questions:

- “What carbide grade (Co %) do you recommend for our specific compound list and why?”

- “What is your standard lead time for manufacturing and re-tipping?” (Downtime is a cost).

- “What non-destructive testing do you perform on every blade before it ships?”

- “Can you provide a certificate of conformance with the actual grade used?”

- “What is your policy and process for analyzing blade failures?”

- “Do you offer different geometric designs or edge preps for different applications?”

- “Can you provide references from companies with similar mixing applications?”

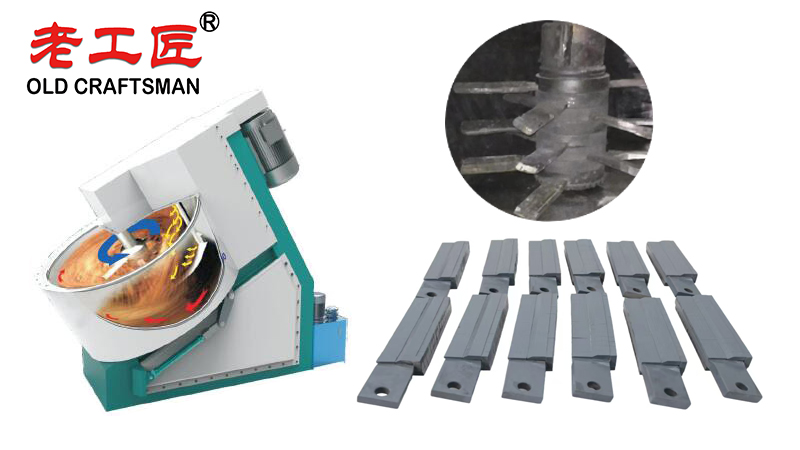

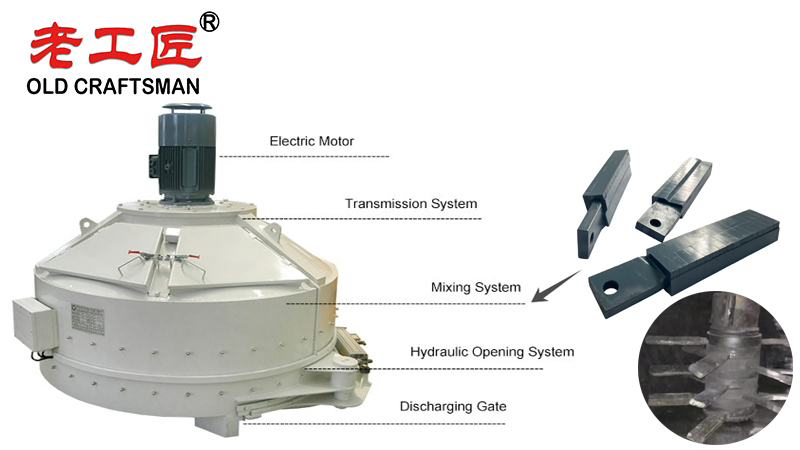

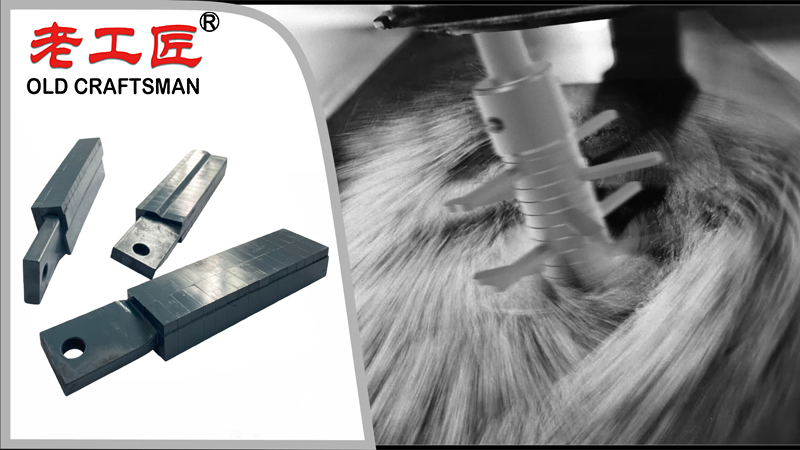

High-performance carbide intensive mixers rely on cutting tools equipped with premium cemented carbide grades to deliver exceptional cutting performance under extreme conditions. The blades feature wear-resistant sharp edges with optimized blade geometry typically a low edge angle combined with convex or flat grinds on both sides of the blade ensuring precise cuts even when processing tough, abrasive materials such as stainless steel or high temperature compounds.

These wear resistant carbide edges maintain their sharpness far longer than conventional steel, providing superior durability and consistent performance at high pressure and elevated temperatures. By selecting the appropriate carbide grade and refining the edge geometry, manufacturers can significantly optimize performance across a wide range of demanding mixing and granulating applications, resulting in cleaner cuts, reduced downtime, and maximum productivity.

Conclusion: Maximizing Durability is a Partnership

The most durable tungsten carbide blade results from a collaboration between you and your supplier. You provide the deep knowledge of your process and materials. A superior supplier provides the expertise in material science and engineering to translate that into a customized tool.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding