Choosing the perfect DTH (Down-The-Hole) hammer drill bit is a critical decision that directly impacts the efficiency, cost, and success of any mining project. There is no single “best” bit, only the best bit for your specific conditions.

Here is a comprehensive guide on how to select the perfect DTH drill bit for your mining project.

The Golden Rule: Match the Bit to the Rock

The fundamental principle of DTH bit selection is rock formation compatibility. Using a hard, abrasive rock bit in a soft, sticky formation (and vice-versa) will lead to catastrophic failure and exorbitant costs.

Step 1: Analyze Your Rock Formation

Before you even look at a bit catalog, you must understand what you’re drilling through.

| Rock Characteristic | What to Look For | Why It Matters |

|---|---|---|

| Hardness & Abrasiveness | Hardness: Resistance to penetration (e.g., Granite, Quartzite). Abrasiveness: Ability to wear away the bit (e.g., Sandstone, Quartz content). | Hard rocks require a robust, impact-resistant bit design. Abrasive rocks demand superior wear resistance in materials and flushing. |

| Compressiveness Strength (UCS) | Measured in MPa (psi). • Soft: < 70 MPa • Medium: 70 – 140 MPa • Hard: 140 – 210 MPa • Very Hard: > 210 MPa | Determines the required impact energy and button size/shape. Higher UCS needs higher impact energy and stronger, larger buttons. |

| Formation Type | • Massive (uniform) • Stratified (layered) • Fractured/Jointed • Fault Zones | Uniform rock allows for consistent bit performance. Layered or fractured rock requires a more durable bit that can handle shock loads and directional changes. |

| Stickiness & Plasticity | Does the rock (e.g., clay, shale) have a tendency to “ball up” or pack in the bit? | Requires an open, efficient flushing design to prevent bit-balling, which kills performance and can lead to stuck rods. |

Step 2: Understand the Key Components of a DTH Bit

To make an informed choice, you need to know what you’re evaluating.

1. Button Type & Material

This is the cutting structure.

- Tungsten Carbide Buttons (Inserts): The standard. The quality of the carbide grade and the manufacturing process (sintering) are crucial.

- Carbide Grade: Softer grades are tougher, harder grades are more wear-resistant but more brittle. Manufacturers use proprietary blends.

- Shape & Arrangement:

- Hemispherical / Spherical: All-round performer. Good for medium to hard, abrasive rock. Balanced between penetration rate and durability.

- Ballistic / Parabolic: More aggressive. Excellent for medium-hard to hard rock. Provides faster penetration but may wear faster than hemispherical in highly abrasive conditions.

- Conical / Pointed: Most aggressive. Best for soft to medium, non-abrasive rock. Prone to breaking in hard or fractured formations.

- Flat / Dome: Extreme wear resistance. Used for the hardest, most abrasive rock. Sacrifices penetration rate for exceptional life.

2. Bit Body Material & Hardening

- Body Steel: Typically high grade, heat treated alloy steel for strength and toughness.

- Surface Hardening: The bit body is often protected by hard facing (e.g., tungsten carbide weld) to resist abrasion from cuttings, especially around the gauge.

3. Flushing System (Air Flow)

- Ports (Flush Holes): The number, size, and location of the holes that channel compressed air to the bottom of the hole.

- Purpose: To remove cuttings, cool the bit, and power the hammer.

- Selection: More/larger ports are better for sticky ground and high penetration rates. Fewer/smaller ports can be better for “chip retention” in certain fractured formations to aid in cleaning.

4. Gauge Protection

- The outer diameter of the bit must be protected to maintain hole size and prevent the bit from getting stuck.

- Gauge Buttons: Extra buttons on the side of the bit.

- Gauge Plates / Wings: Carbide plates welded to the side for maximum abrasion resistance in extremely abrasive formations.

Step 3: Match the Bit Design to Your Rock Analysis

Use the analysis from Step 1 to guide your selection from Step 2.

| Rock Formation Profile | Recommended DTH Bit Characteristics |

|---|---|

| Soft to Medium, Sticky (Clay, Shale, Soft Limestone) | • Button Shape: Conical or large Ballistic for fast penetration. • Flushing: Large, open flush ports to prevent bit-balling. • Gauge: Standard gauge buttons. • Priority: Penetration Rate & Cleaning. |

| Medium to Hard, Abrasive (Sandstone, Abrasive Granite) | • Button Shape: Hemispherical or Ballistic for a balance of penetration and wear. • Flushing: Standard to good flushing. • Gauge Protection: Crucial. Use robust gauge buttons or even gauge plates. • Priority: Wear Resistance & Gauge Protection. |

| Hard, Non-Abrasive (Hard Limestone, Some Basalts) | • Button Shape: Ballistic or Parabolic for aggressive fracturing. • Flushing: Standard. • Gauge: Standard gauge buttons. • Priority: Penetration Rate & Impact Resistance. |

| Very Hard, Massive (Quartzite, Taconite, Very Hard Granite) | • Button Shape: Flat/Dome or small, closely spaced Hemispherical for maximum shock resistance and wear life. • Flushing: Standard. • Gauge: Heavy-duty gauge protection. • Priority: Durability & Shock Resistance. Avoid aggressive shapes that can shatter. |

| Fractured, Faulted, or Layered Formations | • Button Shape: Strong, robust hemispherical to handle shock loads from hitting voids/fractures. • Flushing: Ensure adequate flushing to clear broken material. • Gauge: Good gauge protection is key. • Priority: Toughness & Impact Resistance. Avoid fragile, pointed buttons. |

Step 4: Consider Your Drilling System Parameters

The bit does not work in isolation. It must be compatible with your entire setup.

- Hammer Size & Pressure: A larger hammer delivers more impact energy and requires a larger, more robust bit. Ensure the bit shank (thread) is compatible with your hammer.

- Drill Pipe / Casing Size: This determines the final hole size and thus the bit diameter.

- Air Compressor Capacity (CFM / l/s): Your air volume and pressure must be sufficient to power the hammer AND provide adequate air velocity to clean the hole. Inadequate air is a primary cause of poor performance and stuck bits.

Step 5: The Final Decision Matrix – Cost vs. Performance

You will often have to choose between different bit options and price points.

- Premium Bits: Higher initial cost, but superior metallurgy, carbide quality, and design. They typically offer the lowest cost-per-meter in demanding applications due to longer life and consistent performance.

- Standard/Value Bits: Lower initial cost. Can be a good choice for less demanding, uniform rock or for projects with a very short timeline where capital outlay is the primary concern. May have a higher cost-per-meter.

The Key Metric: Always calculate Cost-Per-Meter.

Cost-Per-Meter = (Bit Cost) / (Total Meters Drilled)

A more expensive bit that drills twice as many meters is almost always the better financial decision.

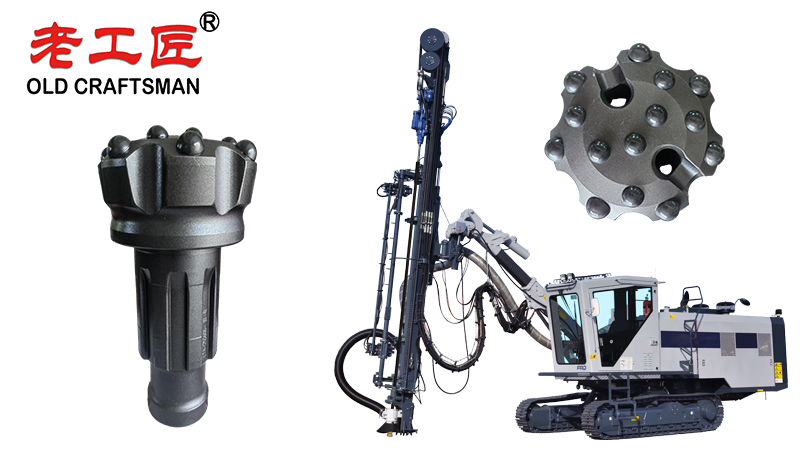

DTH (Down-The-Hole) hammers and DTH drilling bits are widely regarded as some of the most reliable and high performance rock drilling tools for challenging drilling operations. These drilling tools feature a wide range of drill bits that are specifically designed with premium tungsten carbide buttons and carbide tips to deliver exceptional durability, high penetration rates, and superior wear resistant properties. Whether breaking through hard metamorphic rock, abrasive sedimentary rocks, or mixed formations, these high quality bits maintain consistent performance in demanding applications such as water well drilling, mining, construction, and quarrying. Thanks to advanced engineering, the bits feature optimized flushing channels and button configurations that ensure efficient cuttings removal and extended service life, making them a top choice for professionals who require high performance results in the toughest ground conditions.

Summary Checklist for Selection:

- Rock Analysis Done: UCS, abrasiveness, formation structure.

- Button Shape Chosen: Conical (soft), Ballistic (medium hard), Hemispherical (abrasive), Flat (very hard/abrasive).

- Gauge Protection Confirmed: Adequate for the abrasiveness of the rock.

- Flushing System Checked: Suited for rock stickiness and your available air.

- Compatibility Verified: Bit shank matches the hammer, diameter matches the desired hole size.

- Supplier Consulted: Discussed your application with a technical expert from your DTH supplier. They have invaluable experience.

- Pilot Test Planned: If possible, test 2-3 different bit types and measure the cost-per-meter to find the true “perfect” bit for your specific site.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding