Choosing the right carbide crusher wear liners for brand crushers is critical for maximizing wear resistance, reducing downtime, and improving cost efficiency in high abrasion applications. Here’s a structured approach to selecting the best carbide liners:

1. Understand Carbide Liners & Their Benefits

Carbide (typically tungsten carbide, TIC, or ceramic-reinforced) liners offer:

✔ Extreme wear resistance (3-5x longer life than manganese steel in abrasive conditions).

✔ Impact resistance (if using tough carbide grades).

✔ Better crushability for hard, abrasive materials (e.g., quartzite, taconite, recycled concrete).

Best for:

- Ultra abrasive feeds (e.g., granite, iron ore, slag).

- High speed crushing (e.g., VSI crushers, tertiary cone crushers).

- Applications where liner changes are costly or frequent.

2. Match Carbide Type to Your Application

| Carbide Type | Best For | Limitations |

|---|---|---|

| Tungsten Carbide (WC) | Extreme abrasion (e.g., sand, gravel) | Brittle under high impact |

| TIC (Titanium Carbide) | Balanced wear & impact resistance | Higher cost than WC |

| Ceramic Enhanced | Lightweight, corrosion resistant | Not ideal for heavy impact |

| Carbide Reinforced Manganese | Impact + abrasion (e.g., jaw crushers) | Less wear life than pure carbide |

Sandvik & Metso Offerings:

- Sandvik Quarry+™ (Carbide-enhanced) – For cone & jaw crushers.

- Metso Megaliner™ with carbide inserts – For gyratory & cone crushers.

3. Select the Right Crusher Model & Liner Design

- Jaw Crushers (Metso C-series / Sandvik CJ):

- Fixed & moving jaws with carbide strips or full carbide plates.

- Example: Sandvik TIP (Tough Impact Plate) with carbide inserts.

- Cone Crushers (Metso HP/MP, Sandvik CH/CS):

- Mantle & concave liners with carbide reinforced tips.

- Example: Metso MX™ Multi-Action liners (carbide enhanced).

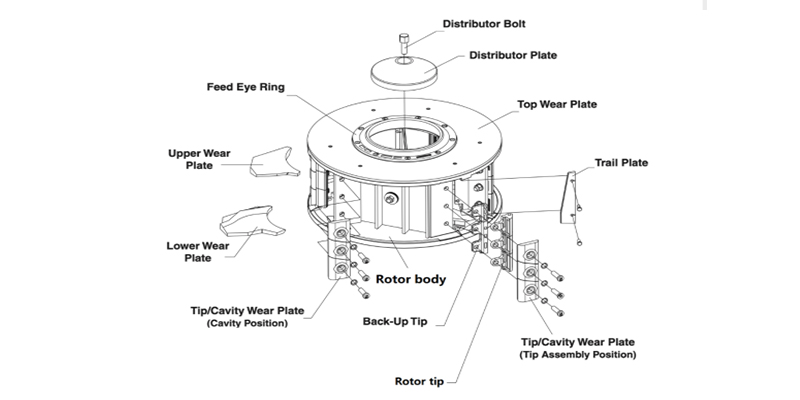

- VSI Crushers:

- Carbide tipped rotor tips & anvils (e.g., Metso Barmac, Sandvik CV).

4. Evaluate Feed Material & Operating Conditions

| Material | Recommended Carbide Solution |

|---|---|

| Granite, Basalt | WC or TIC inserts (high abrasion) |

| Iron Ore, Taconite | Carbide-overlay manganese |

| Recycled Concrete | Hybrid carbide/manganese liners |

| Sand, Gravel | Full carbide plates (VSI rotors) |

Avoid carbide in:

❌ High impact, low abrasion crushing (e.g., soft limestone).

❌ Uncontrolled feed (tramp metal can fracture carbide).

5. OEM vs. Aftermarket Carbide Liners

| Factor | OEM (Sandvik/Metso) | Quality Aftermarket |

|---|---|---|

| Fit & Performance | Guaranteed compatibility | Must verify tolerances |

| Cost | Higher price (premium grade) | 20-40% cheaper (check certifications) |

| Availability | Longer lead times | Faster delivery (stock options) |

Tip: If using aftermarket, ensure:

✔ ISO 9001-certified suppliers.

✔ Matching metallurgy & carbide grade (e.g., YG8 tungsten carbide).

6. Optimize Liner Life & Cost Efficiency

- Use wear monitoring (e.g., Metso LinerVision, Sandvik My Sandvik).

- Adjust crusher settings (CSS, speed) to reduce unnecessary wear.

- Rotate/flip liners to distribute wear evenly.

7. Top Recommendations

| Crusher Type | Best Carbide Liner Choice |

|---|---|

| Sandvik Cone (CH/CS) | Quarry+™ carbide enhanced concaves |

| Metso HP Cone | Megaliner™ with carbide inserts |

| Jaw Crushers | TIP (Sandvik) / C-series carbide jaws (Metso) |

| VSI Crushers | Carbide tipped rotor & anvils |

Final Advice

- For extreme abrasion: Pure carbide or TIC inserts.

- For impact + abrasion: Carbide reinforced manganese.

- Consult OEM engineers for custom solutions

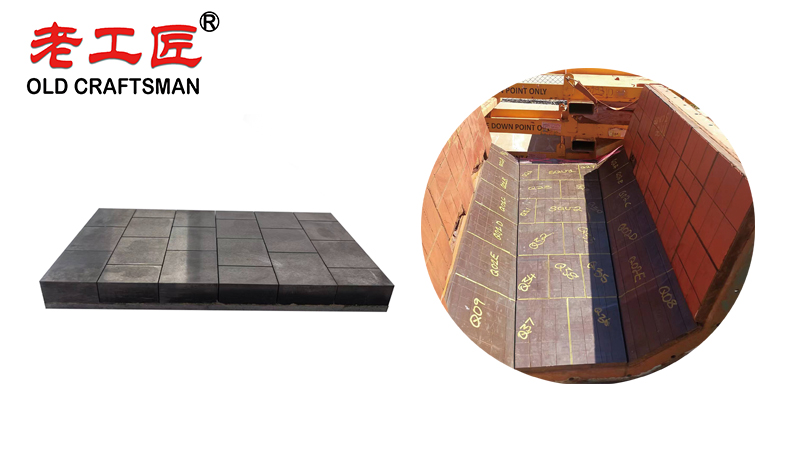

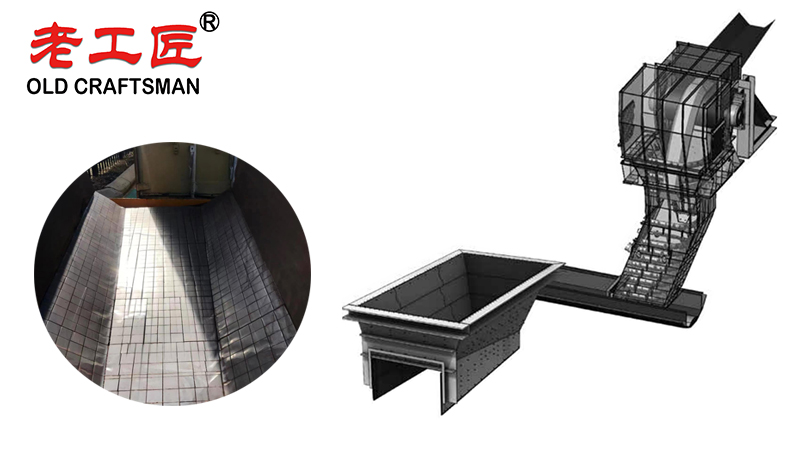

In the demanding world of crushing applications, crusher wear liners and wear parts play a critical role in optimizing the crushing process across various crushing stages. Designed for a wide range of specific applications, these components deliver high performance even when handling highly abrasive feed material or material entering under high temperatures. They must withstand different types of wear, with abrasion wear being the most common, while maintaining exceptional mechanical properties such as high strength and superior wear resistant materials. Achieving optimal reduction ratios and minimal wear rate requires careful selection of materials that balance durability with cost effectiveness. Rigorous testing methods ensure these wear parts provide long lasting protection, reducing downtime and enhancing overall efficiency in challenging crushing environments.

Our mining carbide crusher wear liners are specifically engineered for a wide range of highly abrasive crushing applications, including cone crushers, jaw crushers, and high speed impact crushing. Manufactured from premium abrasion resistant carbide materials, these high-quality wear plates demonstrate exceptional ability to withstand extreme abrasion wear and tough feed materials with large feed size. By significantly extending wear life and lowering wear rate, they effectively reduce downtime and overall operating costs throughout the entire crushing process, delivering outstanding performance and reliability in the most demanding mining environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding