Choosing the right mining conveyor belt tungsten carbide scraper involves considering several key factors to ensure optimal performance, durability, and cost effectiveness. Here’s a step-by-step guide:

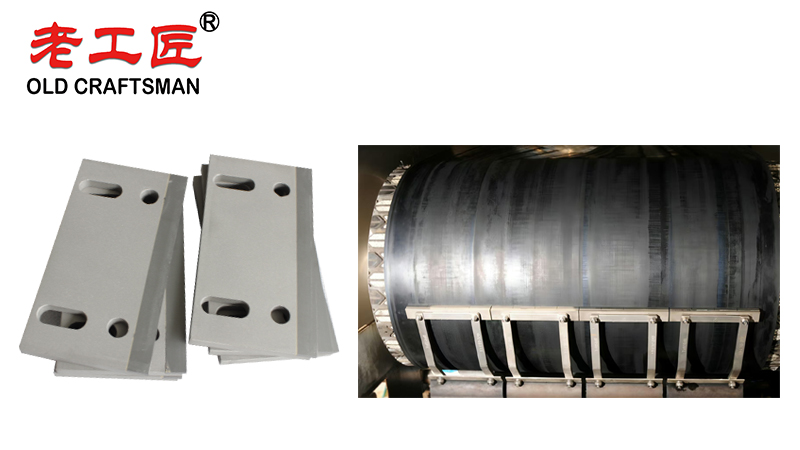

1. Determine the Scraper Type

Conveyor belt scrapers come in different designs:

- Primary Scrapers (Pre-Cleaners): Remove bulk material right after the discharge point.

- Secondary Scrapers (Cleaners): Fine tune cleaning for residual material.

- Tungsten Carbide-Tipped (TCT) Scrapers: Best for heavy duty mining applications due to extreme hardness and wear resistance.

2. Consider the Conveyor Belt Conditions

- Belt Speed: High speed belts require robust scrapers with strong carbide tips.

- Belt Material & Texture: Rough or textured belts need more aggressive scrapers.

- Material Type: Abrasive ores (like iron, coal, or copper) demand high wear resistant scrapers.

3. Evaluate Tungsten Carbide Quality

- Grade of Tungsten Carbide: Higher grade carbide (e.g., YG8, YG11) offers better wear resistance.

- Tip Shape & Design: Chisel, square, or beveled tips affect cleaning efficiency.

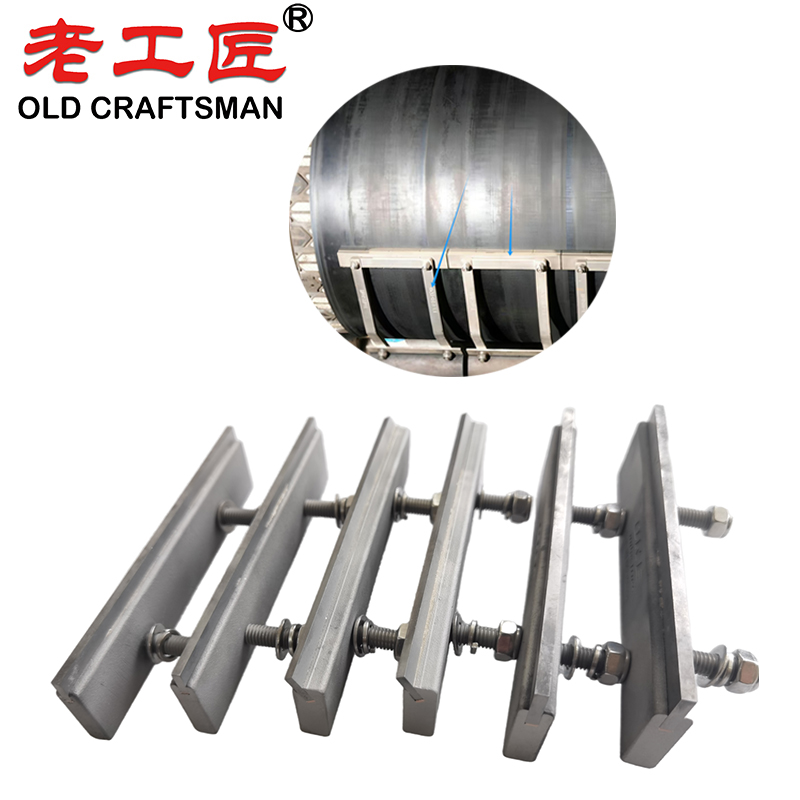

- Bonding Method: Brazed carbide tips are stronger than mechanically clamped ones.

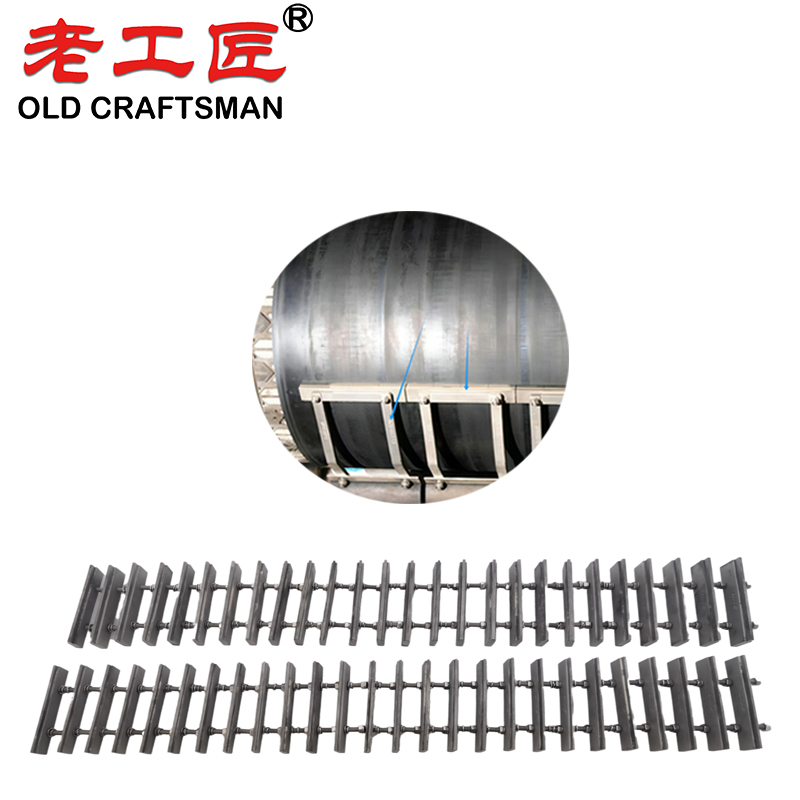

4. Check Mounting & Tensioning System

- Adjustability: A tensioning system ensures consistent blade contact.

- Spring or Pneumatic Pressure: Proper pressure prevents belt wear while maintaining cleaning efficiency.

5. Assess Environmental Factors

- Moisture & Corrosion: Wet or corrosive environments may require stainless steel holders.

- Temperature Extremes: High heat may affect scraper material integrity.

6. Compare Lifespan & Maintenance

- Longevity: Tungsten carbide scrapers last longer than polyurethane or steel alternatives.

- Ease of Replacement: Modular designs allow quick blade changes without removing the entire assembly.

7. Cost vs. Performance Balance

- Initial Cost vs. Long-Term Savings: Tungsten carbide scrapers are more expensive upfront but reduce downtime and replacement costs.

8. Manufacturer Reputation & Support

- Choose a reputable supplier with proven mining industry experience.

- Look for warranty and after sales support.

Recommended Tungsten Carbide Scrapers for Mining

- Primary Scrapers: Heavy duty TCT blades with high pressure tensioning.

- Secondary Scrapers: Fine cleaning carbide scrapers with adjustable angles.

Final Tip

Consult with a conveyor belt specialist or the scraper manufacturer to match the right tungsten carbide scraper to your specific mining operation.

High-quality tungsten carbide rings have revolutionized mining conveyor belt scrapers, delivering exceptional long term performance in both surface and underground heavy machinery environments. Thanks to tungsten’s extremely high melting point and outstanding ranking on the Mohs scale, these belt scraper blades offer significantly reduced wear and superior resistance to scratches compared to traditional precious metals or standard steel. This unmatched scratch resistance and durability ensure the bulk of material is efficiently removed from the conveyor system without frequent blade replacement, drastically cutting downtime and maintenance costs. Increasingly, operators are choosing these innovative, high performance tungsten carbide designs for their proven ability to withstand the harshest raw material handling conditions while keeping conveyor belts clean and running smoothly over extended periods much like how a tungsten wedding ring is chosen for its lifelong toughness and beauty.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding