Here’s a detailed breakdown of how tungsten carbide chute liners resist wear and tear, from the atomic level to the operational benefits.

The Core Principle: The Hardness vs. Toughness Duo

The secret to tungsten carbide’s (often referred to as “carbide” in the industry) success lies in its unique combination of two properties that are often mutually exclusive in other materials:

- Extreme Hardness

- Good Toughness

Think of it like this: A diamond is incredibly hard, but if you hit it with a hammer, it will shatter (it’s brittle). A car tire is very tough and won’t shatter, but it’s soft and can be easily cut or abraded. Tungsten carbide finds the perfect middle ground for abrasive applications.

How It Works: The Mechanisms of Wear Resistance

When abrasive material like iron ore, copper ore, or coal slides down a chute, it causes wear through several mechanisms. Tungsten carbide resists them all.

1. Resistance to Abrasive Wear (The Main Event)

- What it is: This is the “grinding” action, like sandpaper, where hard, sharp particles in the ore scrape and gouge the liner surface.

- How Carbide Resists It:

- Microscopic Structure: Tungsten carbide is a “ceramic-metallic” composite (a cermet). It consists of extremely hard tungsten carbide ceramic grains (the “sand”) held together by a tough cobalt or nickel metal binder (the “glue”).

- The “Sandpaper Test”: For a material to abrade tungsten carbide, the abrasive particle must be harder than the carbide grains. Very few minerals are harder. As the ore slides over the liner, the hard carbide grains blunt and deflect the abrasive particles, preventing them from digging in and removing material.

2. Resistance to Impact Wear

- What it is: This is the damage from large, heavy lumps of rock hitting the liner at high speed, causing chipping, cracking, or deformation.

- How Carbide Resists It:

- The Binder’s Role: The cobalt/nickel binder provides crucial toughness. It gives the material some “give,” allowing it to absorb the energy of an impact without shattering like a pure ceramic would.

- Compressive Strength: Tungsten carbide has an exceptionally high compressive strength, meaning it can withstand massive crushing forces without deforming, which is exactly what happens during a direct impact.

3. Resistance to Erosive Wear

- What it is: A more focused form of abrasion, often caused by a high velocity stream of fine particles sliding or impinging on the surface at an angle.

- How Carbide Resists It:

- Low Friction Coefficient: The smooth, hard surface of a carbide liner creates less friction with the sliding material than steel. This not only reduces wear but also improves material flow and reduces the risk of build-up or blockages.

- Same Hardness Principle: Just like with abrasion, the hard grains resist the cutting action of the high speed particles.

The Design Advantage: How Liners Are Engineered for Performance

Tungsten carbide liners aren’t just flat plates; their design is optimized for maximum life.

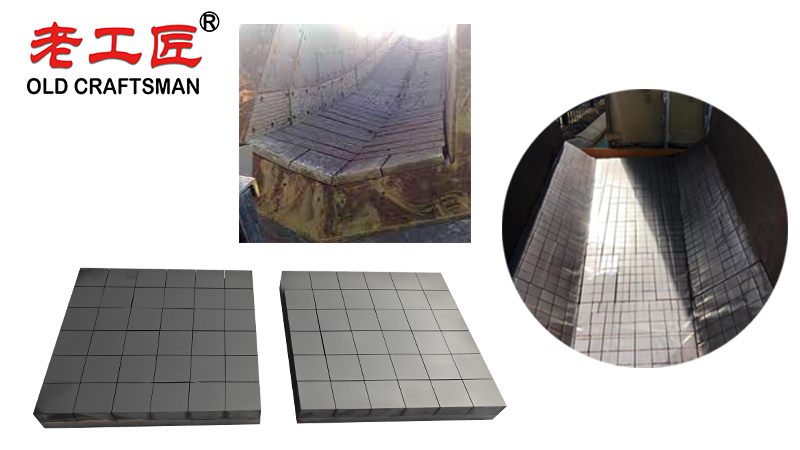

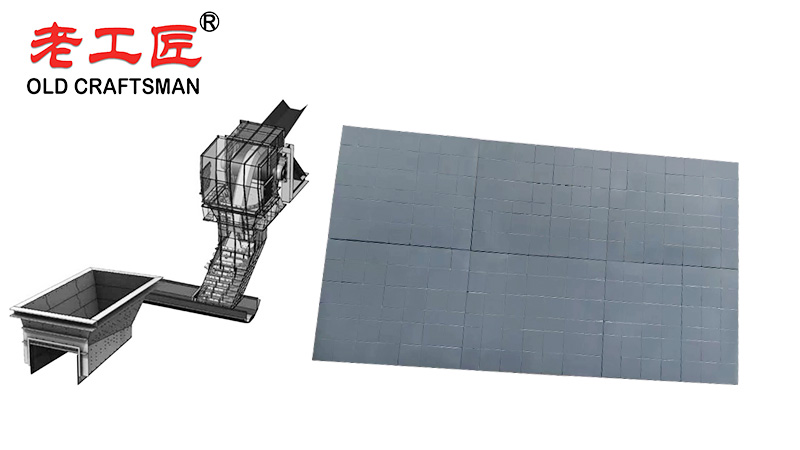

- Tile-Based System: Carbide liners are typically not one solid piece. They are made up of many individual tiles or bricks that are embedded into a steel holder or welded onto a backing plate.

- Benefit: If an extremely severe impact occurs, only a single tile might be damaged and can be replaced easily, instead of replacing an entire chute section. This makes maintenance faster and cheaper.

- Strategic Placement: Because carbide is more expensive than steel upfront, it is used strategically in areas of highest wear (the “wear zone”), such as:

- Impact points where material first lands.

- Sharp bends or curves in the chute.

- The bottom of the chute where sliding velocity is highest.

Comparison to Other Materials

To fully appreciate tungsten carbide, it helps to compare it to common alternatives:

| Material | Key Characteristic | How it Wears Out | Compared to Carbide |

|---|---|---|---|

| Mild Steel | Soft and Ductile | Wears quickly by abrasion, can dent and deform. | Carbide lasts 20-50x longer, or more. |

| AR400 / Hardened Steel | Hard but less tough | Hardness resists abrasion for a while, but eventually wears thin. Can work harden. | Carbide is significantly harder and more wear resistant. |

| UHMW Plastic | Soft and Tough | Wears by abrasion and can be gouged easily. Excellent for non-stick. | Carbide is far superior for pure abrasion resistance. |

| Ceramic Tiles | Very Hard | Extremely brittle; can shatter on impact. | Carbide is much tougher and more impact resistant. |

The Bottom Line: Operational Benefits

The superior wear resistance of tungsten carbide chute liners translates directly to the mine’s bottom line:

- Massively Extended Service Life: Chutes can last for years instead of months, drastically reducing downtime for liner replacement.

- Reduced Maintenance Costs: Fewer change outs mean lower labor costs and less inventory of spare parts.

- Increased Production Uptime: The plant runs longer without having to stop for chute maintenance.

- Improved Safety: More reliable chutes with less risk of unexpected failure or blow-outs.

- Better Flow: The hard, smooth surface prevents material build-up, reducing blockages that require dangerous manual clearing.

In summary, tungsten carbide chute liners resist wear and tear by combining the hardness of a ceramic with the toughness of a metal. This unique combination allows them to withstand the relentless assault of abrasive and impactive forces in a mining environment, making them one of the most cost effective solutions for protecting critical infrastructure over the long term.

Silicon carbide (SiC) mining chute liners are widely used in heavy duty industrial applications where extreme wear resistance is critical. Unlike traditional stainless steel liners that suffer rapid material removal under highly abrasive particles, silicon carbide offers exceptional hardness (second only to diamond) and high strength, even at high temperatures exceeding 1400 °C. Although silicon carbide can be produced from naturally occurring raw materials, most industrial grade SiC is manufactured synthetically to achieve consistent mechanical properties and purity.

Compared to cost effective aluminum oxide (alumina), silicon carbide provides significantly longer service life in severe sliding and impact abrasion environments, making it the preferred choice for wear parts in ore and coal handling chutes. Its sharp cut edges (when fractured) combined with outstanding toughness help resist different types of wear including gouging, grinding, and erosion. Standardized test methods such as ASTM G65 (dry sand/rubber wheel) consistently demonstrate that SiC liners outperform both metallic and other ceramic options, ultimately reducing costs through extended replacement intervals and minimized downtime in the most demanding mining operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding