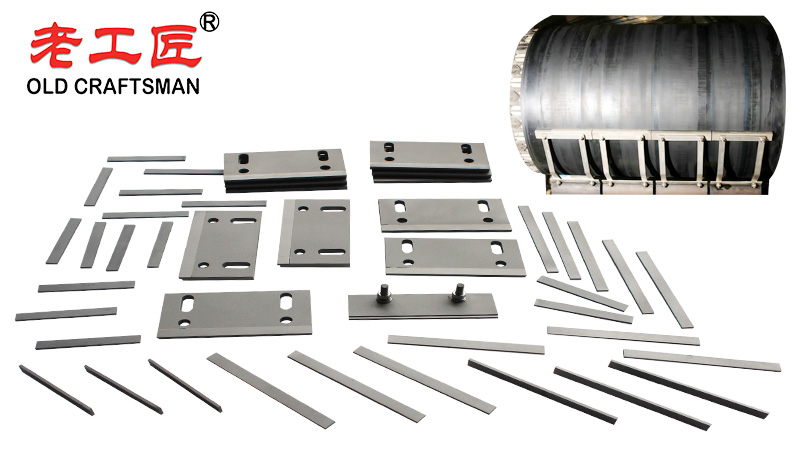

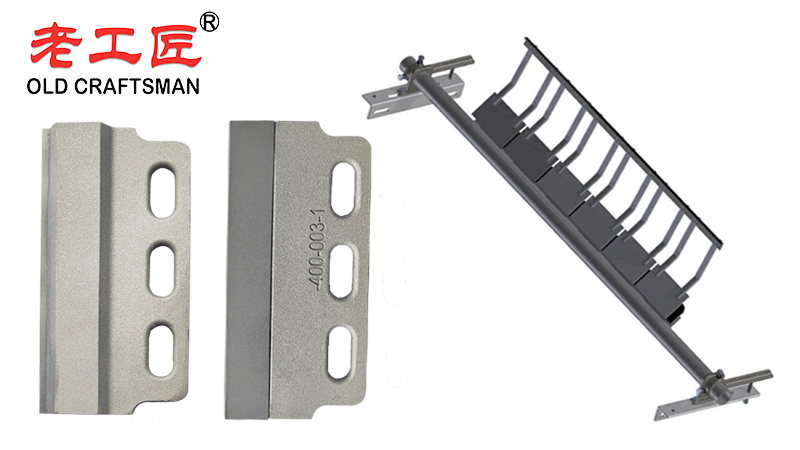

Tungsten carbide conveyor scrapers play a crucial role in enhancing the safety and cleanliness of mining operations by improving the efficiency and reliability of conveyor belt systems. Here’s how they contribute:

1. Enhanced Wear Resistance & Longevity

- Tungsten carbide is one of the hardest materials available, making scrapers highly resistant to abrasion from rough mining materials like coal, ore, and aggregates.

- This durability reduces the frequency of replacements, minimizing downtime and maintenance related hazards.

2. Improved Belt Cleaning Efficiency

- Tungsten carbide scrapers effectively remove sticky or abrasive material buildup from conveyor belts, preventing carryback (residual material that falls off the belt).

- Cleaner belts reduce spillage along the conveyor path, minimizing slip-and-fall risks and keeping work areas safer.

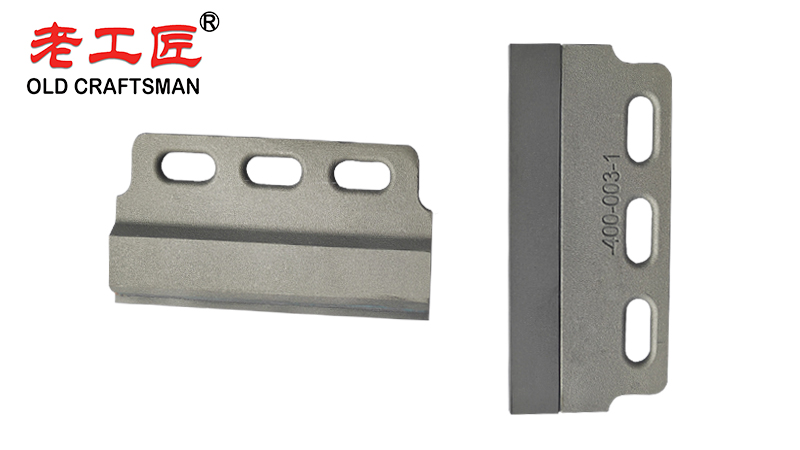

3. Reduced Belt Damage & Maintenance Costs

- Unlike softer scrapers, tungsten carbide blades maintain a sharp edge longer, ensuring consistent cleaning without gouging or damaging the belt.

- Less belt wear extends the lifespan of the conveyor system, reducing unexpected failures and associated safety risks.

4. Fire & Explosion Risk Mitigation

- In coal mining, accumulated dust and material can pose fire and explosion hazards. Effective scraping reduces dust buildup, improving air quality and lowering combustion risks.

5. Corrosion & Chemical Resistance

- Tungsten carbide performs well in wet or chemically aggressive environments (e.g., acid-leaching operations), resisting degradation better than steel or polyurethane alternatives.

6. Automation & Reduced Manual Cleaning

- Efficient scrapers reduce the need for workers to manually clean belts or remove debris, decreasing exposure to moving machinery and hazardous materials.

Conclusion

By ensuring cleaner belts, minimizing maintenance, and reducing operational hazards, tungsten carbide conveyor scrapers contribute to safer, more efficient, and cost effective mining operations. Their durability and performance make them a preferred choice in heavy duty mining applications.

In the United States, conveyor systems play a critical role in material handling across industries ranging from food processing to coal production. These systems efficiently move items and bulk material through assembly lines, loading and unloading zones, and storage areas, resulting in significantly increased productivity. Common types of conveyor systems include belt systems equipped with a conveyor belt scraper to remove residue, roller conveyors for smooth transport of heavy items, chain conveyors for robust applications, and overhead conveyors that save valuable floor space. In mining, particularly in room-and-pillar operations for both surface and underground coal beds, heavy duty handling systems with durable rollers and belts are essential for transporting coal safely and continuously, ensuring the entire conveyor system works reliably under demanding conditions.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding