Executive Summary

Tungsten Carbide (TC) edge blocks are not merely a wear part; they are a fundamental, high performance component that transforms the High-Pressure Grinding Roll (HPGR) from a competent crusher into a model of operational excellence. By drastically increasing wear life, improving availability, and maintaining consistent performance, TC edge blocks directly impact the bottom line through reduced operating costs, enhanced throughput, and superior product quality.

1. Understanding the HPGR and the “Edge” Challenge

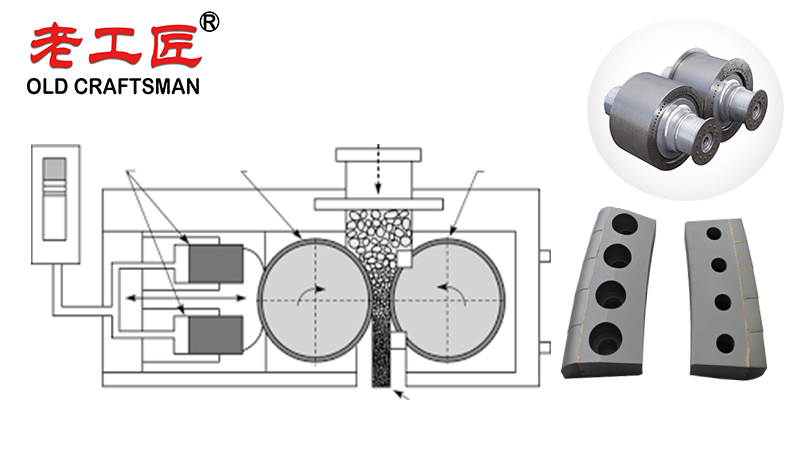

An HPGR operates by compressing a feed material between two counter-rotating rolls. One roll is fixed, and the other is movable, generating extremely high pressure (e.g., 50-500 MPa) that causes inter-particle comminution. The key to generating this pressure is the ability to trap the feed material.

This is where the edge comes in. Traditionally, rolls had a smooth surface. However, without a way to “grip” the feed, material would slip on the roll surface, drastically reducing throughput and efficiency.

The solution was the development of studded rolls. Hundreds of tungsten carbide studs are pressed into the roll surface. These studs:

- Provide grip: They bite into the feed material, pulling it into the crushing zone (the “nip”).

- Transfer pressure: They are the primary point of contact for transmitting pressure to the ore particles.

However, the ends of the rolls present a unique problem: the edge effect. At the sides, there is no containing wall, so material is under lower pressure and can extrude sideways, escaping proper comminution. This leads to:

- Rapid wear on the ends of the rolls, creating a “dished” or “hourglass” profile.

- Uneven product distribution: The improperly crushed edge material reports as coarse, poor-quality product.

- Reduced overall efficiency as energy is wasted.

2. The Role of Tungsten Carbide Edge Blocks

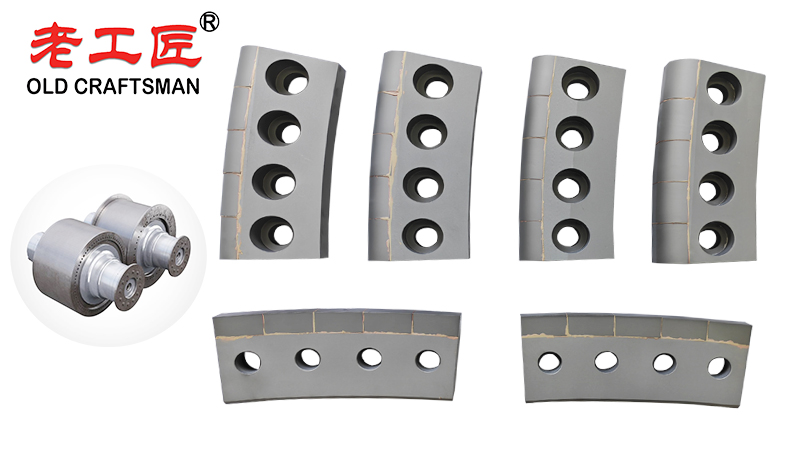

Tungsten Carbide edge blocks are specially designed, reinforced structures that are bolted onto the ends of the HPGR rolls. Their primary function is to contain the feed pile at the roll edges, effectively solving the edge effect problem.

How They Work:

- Containment: They act as a physical wall, preventing the sideways extrusion of material.

- Pressure Generation: By containing the feed, they allow full operating pressure to be maintained across the entire width of the roll.

- Wear Absorption: They are sacrificial components made from ultra-wear-resistant materials designed to protect the much more expensive and complex main roll body.

3. How TC Edge Blocks Drive Operational Excellence

The implementation of robust TC edge blocks translates directly into key performance indicators (KPIs) that define operational excellence.

A. Maximized Availability & Reduced Downtime

- Extended Wear Life: TC is one of the hardest materials available (Second only to diamonds on the Mohs scale). Edge blocks made from premium-grade TC can last 6 to 24 months, compared to weeks or months for traditional steel edges.

- Predictable Maintenance Scheduling: Their long and predictable life allows planners to schedule roll maintenance during planned shutdowns, eliminating costly unplanned downtime for emergency edge replacements.

- Faster Change-Out: Modern edge block designs are bolted on, making them quicker and safer to replace than welded or complex integrated solutions.

B. Superior Operational Consistency and Product Quality

- Stable Roll Gap Profile: By resisting wear at the edges, the rolls maintain a parallel gap across their entire width throughout the campaign. This ensures a consistent product size distribution (PSD) from center to edge.

- Elimination of “Dishing”: No more hourglass shaped rolls. This consistent profile ensures that energy input and crushing pressure are uniform, leading to a higher proportion of the desired product size and fewer coarse, uncrushed particles.

- Improved Liberation: Consistent pressure leads to more micro-cracks in the ore particles, which improves downstream grinding efficiency in ball mills (a major energy consumer).

C. Enhanced Throughput and Energy Efficiency

- Optimized Feed Draw-Down: Effective edge containment ensures the entire roll width is used to draw feed into the nip. There is no “dead zone” at the edges, maximizing the utilization of the crushing surface area.

- Higher Specific Throughput: With no material escaping un-crushed, more tons per hour are processed effectively for the same machine size and energy input.

- Lower Specific Energy Consumption (kWh/t): Because the machine operates at peak efficiency with no energy wasted on slippage or re-crushing, the energy required to grind each ton of ore is minimized. This is one of the biggest cost savings in comminution.

D. Reduced Total Operating Costs (OPEX)

- Lower Parts Consumption: Fewer change-outs mean direct savings on the cost of edge blocks themselves.

- Reduced Labor Costs: Less frequent maintenance means fewer maintenance hours spent on dangerous and arduous roll rebuilding tasks.

- Lower Energy Costs: As mentioned, improved efficiency directly reduces the largest cost element in grinding: electricity.

- Protection of Capital Assets: By protecting the roll body from wear, the life of the core HPGR unit a multi-million dollar asset is extended, delaying CapEx for replacement.

4. Key Considerations for Implementation

To fully realize these benefits, operations must:

- Select the Right Grade: Not all tungsten carbide is equal. The grade must be matched to the ore’s abrasiveness (e.g., high abrasion vs. high impact).

- Optimize Design: The geometry of the block (size, angle, profile) must be designed for the specific HPGR model and application.

- Ensure Proper Installation: Precise torqueing procedures are critical to prevent block loosening or failure.

- Monitor and Maintain: Regular inspection for block integrity and wear is essential for predictive maintenance.

The adoption of HPGR Carbide Edge Block long term technology in the mining and cement industries in the United States has proven to deliver significant specific energy reductions compared to traditional crushing methods, often lowering energy consumption by 20–40 %. These energy savings directly translate into lower energy bills and substantial cost savings for industrial facilities. At the same time, the rapid shift toward electric vehicles, heat pumps for space and water heating, and expanded renewable energy capacity is dramatically reducing greenhouse gas emissions while improving overall energy productivity. Despite increasing energy demand from population growth and electrification, the nation is achieving higher energy output per unit of fossil fuel consumed, with many households and businesses saving money through efficiency upgrades and cleaner technologies. The net result is a powerful combination of saved energy, reduced reliance on natural gas and other fossil fuels, and a more sustainable, high energy future that delivers both environmental and economic benefits.

Conclusion

Tungsten Carbide edge blocks are a critical enabling technology for HPGRs. They are a prime example of how a strategic investment in a single component can catalyze a chain reaction of improvements across availability, throughput, product quality, and cost. By solving the fundamental “edge effect” problem, TC edge blocks unlock the full potential of HPGR technology, making them indispensable for achieving true operational excellence in modern, cost sensitive, and energy conscious mineral processing operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding