Tungsten Carbide (WC) flanges are a critical technological advancement that directly and significantly improve the productivity of High Pressure Grinding Rolls (HPGR). They do this by solving the primary wear problem inherent in the HPGR’s operating principle.

Here’s a detailed breakdown of how tungsten carbide flanges improve HPGR productivity, moving from the basic problem to the specific benefits.

The Core Problem: The “Edge Effect” in HPGRs

To understand the solution, we must first understand the problem.

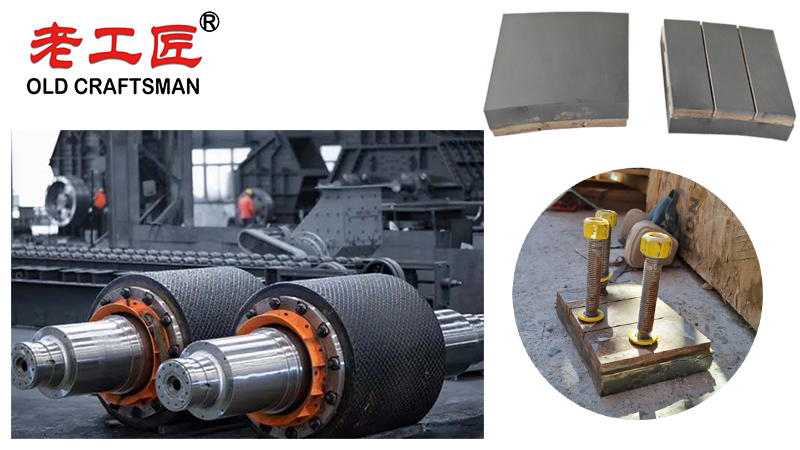

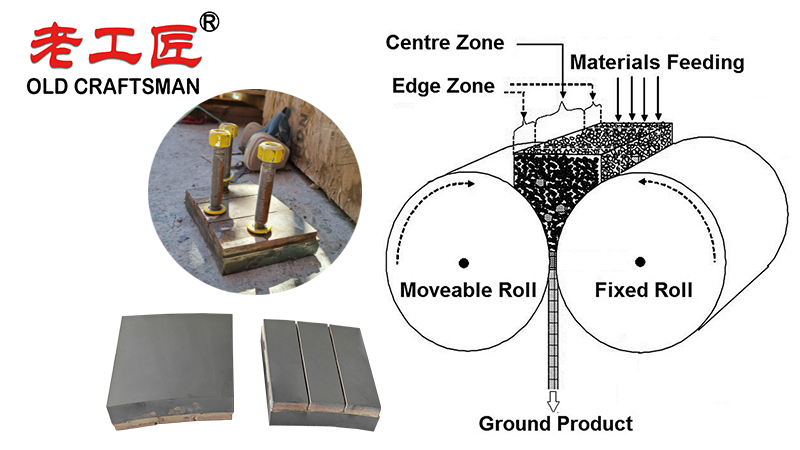

- HPGR Function: An HPGR crushes ore by feeding it between two counter-rotating rolls. The rolls are pressed together with extremely high pressure (e.g., 4-7 N/mm²), which compacts the feed material into a “cake” and causes inter-particle crushing.

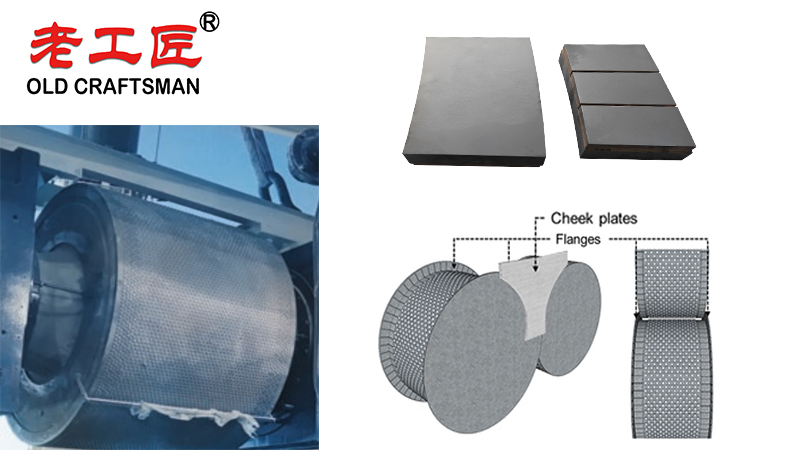

- The Flange’s Role: Flanges are raised rings on the outer edges of the rolls. Their job is to contain the feed material within the crushing zone and maintain the necessary pressure for effective comminution.

- The Wear Problem (Edge Effect): As the ore is compressed, some material tries to escape sideways. This escaping material creates intense, sliding abrasion on the flanges. This is known as the “edge effect.” With traditional steel flanges, this abrasion causes them to wear down very quickly.

Consequences of Worn Flanges:

- Reduced Throughput: Worn flanges can’t contain the feed properly. Ore slips out the sides without being crushed, reducing the effective feed rate and machine throughput.

- Poor Product Quality: The “cake” produced will have uncrushed material at the edges, leading to a less uniform product size distribution. This negatively impacts downstream processes like ball milling.

- Frequent Downtime: Steel flanges need to be rebuilt or replaced often, leading to significant unplanned downtime for maintenance.

How Tungsten Carbide Flanges Solve This Problem

Tungsten carbide is a composite material known for its exceptional hardness and wear resistance. It is significantly harder than the most abrasive components in ore (like quartz). By applying tungsten carbide to the flanges, the “edge effect” problem is dramatically mitigated.

1. Unmatched Wear Resistance (The Primary Benefit)

- Mechanism: Tungsten carbide flanges wear down orders of magnitude slower than hardened steel flanges. A WC flange can last 5,000 to 10,000+ hours, compared to a few hundred hours for a standard steel flange.

- Productivity Impact: This directly translates to a massive increase in uptime. The HPGR can run for months or even years without needing a flange replacement, maximizing its availability for crushing ore.

2. Consistent Performance and Throughput

- Mechanism: Because the WC flanges maintain their profile for much longer, they consistently contain the feed material within the crushing zone.

- Productivity Impact: This ensures a stable and predictable throughput and a consistently high quality product (the “cake”) throughout the entire flange life. Operators don’t have to constantly adjust parameters to compensate for flange wear.

3. Improved Energy Efficiency

- Mechanism: Worn steel flanges allow ore to escape, meaning the HPGR has to work harder (use more energy) to achieve the same crushing effect, or it simply operates less efficiently. The consistent geometry of WC flanges ensures that the energy input from the rolls is used efficiently for crushing, not wasted on material bypass.

- Productivity Impact: Lower energy consumption per ton of ore processed is a direct cost saving and an important sustainability metric.

4. Reduced Maintenance Costs and Labor

- Mechanism: The long service life of WC flanges drastically reduces the frequency of maintenance interventions. This saves on:

- Labor Costs: Fewer hours spent on dangerous and labor intensive flange replacement.

- Parts Costs: Fewer replacement flanges need to be purchased and stocked.

- Heavy Equipment: Less frequent use of cranes and other equipment for maintenance tasks.

- Productivity Impact: Lower operating costs and freed-up maintenance resources that can be deployed elsewhere in the plant.

5. Enhanced Safety

- Mechanism: HPGR flange replacement is a high risk activity involving heavy lifting, confined spaces, and potential for injury. By reducing the frequency of this task, the exposure of maintenance personnel to these hazards is significantly reduced.

- Productivity Impact: While primarily a safety benefit, this also contributes to productivity by avoiding the downtime and disruption associated with safety incidents.

Summary Table: Steel vs. Tungsten Carbide Flanges

| Feature | Steel Flanges | Tungsten Carbide Flanges | Impact on HPGR Productivity |

|---|---|---|---|

| Wear Life | Short (100s of hours) | Very Long (1,000s of hours) | Massively Increased Uptime |

| Performance Consistency | Degrades quickly over time | Remains stable for long periods | Stable Throughput & Product Quality |

| Maintenance Frequency | Very High | Very Low | Reduced Downtime & Labor Costs |

| Energy Efficiency | Decreases as flanges wear | Remains consistently high | Lower Operating Cost per Ton |

| Safety | High-risk, frequent interventions | Fewer interventions required | Improved Safety & Reduced Risk |

In modern cement plants and mining operations, HPGR (High Pressure Grinding Rolls) equipped with cemented carbide flanges and metal matrix composite studded rollers operate under extreme high pressure and high temperature conditions across a wide range of ore types. These high performance rollers, typically manufactured from wear resistant stainless steel bases with cemented carbide inserts, deliver superior service life and consistently sharp cut edges while maintaining excellent tensile strength and a low coefficient of thermal expansion. To minimize unplanned downtime and cut costs, an effective maintenance strategy combines preventive maintenance tasks (regular inspection of carbide stud integrity and flange condition) with predictive maintenance using real-time vibration, temperature, and wear monitoring systems. This data driven approach allows maintenance technicians and maintenance workers to generate targeted work orders precisely when needed, significantly extending the lifespan of these critical cutting tools and optimizing overall manufacturing processes in the HPGR circuit.

Conclusion

Tungsten carbide flanges are not just an incremental improvement; they are an enabling technology for HPGRs in highly abrasive mining applications. By solving the critical wear problem at the edges of the rolls, they transform the HPGR from a high maintenance machine into a reliable, high availability workhorse.

The productivity gains are realized through a combination of:

- Maximized Uptime

- Consistent, High Throughput

- Lower Energy and Maintenance Costs

For any mining operation relying on HPGR technology for energy efficient comminution, the use of tungsten carbide flanges is a essential strategy for maximizing productivity and profitability.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding