Tungsten carbide scrapers are highly effective in reducing conveyor belt wear in mining operations due to their exceptional hardness, durability, and wear resistance. Here’s how they help:

1. Exceptional Hardness & Wear Resistance

- Tungsten carbide (WC) is one of the hardest materials available (rated ~9 on the Mohs scale), significantly harder than steel or rubber conveyor belts.

- This hardness allows carbide scrapers to clean belts aggressively without wearing down quickly, unlike traditional polyurethane or steel scrapers.

2. Effective Material Clean-Up

- Sticky or abrasive materials (e.g., coal, ore, limestone) can adhere to conveyor belts, causing carryback and increasing wear.

- Tungsten carbide scrapers efficiently remove these residues, preventing material buildup that accelerates belt abrasion.

3. Reduced Belt Surface Damage

- Unlike softer scrapers that may deform or wear unevenly, carbide scrapers maintain a consistent edge, ensuring smooth contact with the belt.

- This minimizes gouging or scoring, extending the belt’s lifespan.

4. Long Service Life

- Tungsten carbide scrapers last significantly longer than conventional alternatives, reducing replacement frequency and downtime.

- This lowers maintenance costs and improves operational efficiency.

5. Corrosion & Impact Resistance

- Resistant to chemical corrosion from harsh mining environments (e.g., moisture, acidic/alkaline materials).

- Withstands impact from large, abrasive particles without chipping or breaking.

6. Cost Efficiency Over Time

- Although initial costs are higher than polyurethane or steel scrapers, their extended lifespan and reduced belt wear lead to long-term savings.

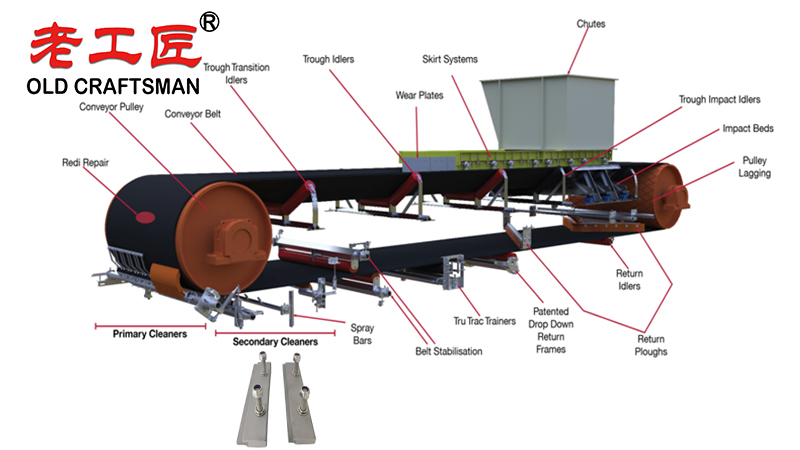

Applications in Mining

- Ideal for heavy-duty conveyors handling coal, iron ore, copper, and other abrasive materials.

- Used in primary and secondary cleaning systems to maximize belt protection.

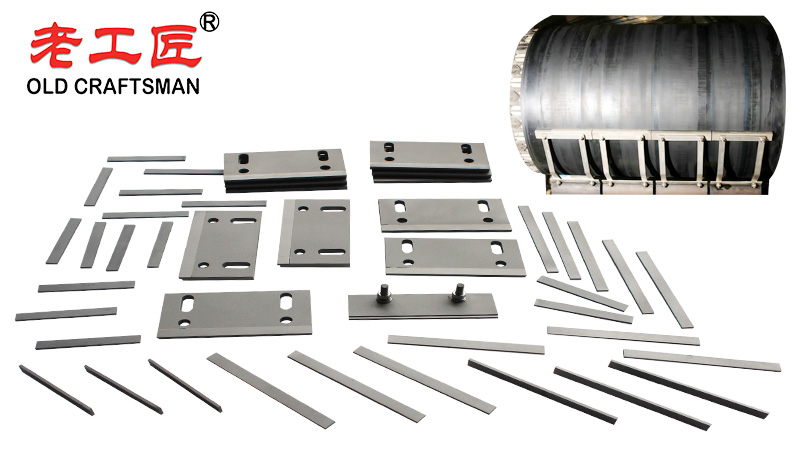

High-quality conveyor belt scrapers designed for mining applications must deliver exceptional abrasion resistance and heat resistance to withstand the extreme conditions of high temperature conveyor systems and high abrasion environments. The selected resist material combines high strength, outstanding mechanical properties, and a low coefficient of friction, ensuring the belt surface stays clean while minimizing wear on both the scraper and the belt itself.

These high performing, impact resistant wear parts maintain belts clean even under heavy loads and wide range of operating temperatures, significantly extending service life and keeping the system running smoothly. With superior durability against high abrasion and potential issues caused by material build-up, regular maintenance intervals are greatly reduced, resulting in lower downtime and higher overall productivity in demanding mining operations.

Conclusion

Tungsten carbide scrapers enhance conveyor belt longevity by minimizing wear from abrasion, carryback, and improper cleaning. Their durability and efficiency make them a cost effective solution for mining operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding