Tungsten carbide (WC) wear plates and flanges significantly improve the productivity of High Pressure Grinding Rolls (HPGR) by enhancing durability, reducing downtime, and optimizing grinding efficiency. Here’s how they contribute:

1. Extreme Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV 1500-2000), far surpassing steel in abrasion resistance.

- HPGRs operate under high pressure (50-300 MPa), causing severe wear on rolls and flanges. WC wear plates protect critical surfaces, extending service life by 3-5 times compared to traditional steel components.

2. Reduced Downtime & Maintenance Costs

- WC-lined flanges and wear plates minimize frequent replacements, reducing unplanned shutdowns.

- Fewer maintenance intervals mean higher operational availability, crucial for continuous mining and mineral processing.

3. Consistent Grinding Performance

- Worn flanges and plates lead to uneven roll gaps, reducing grinding efficiency.

- Tungsten carbide maintains its shape longer, ensuring stable pressure distribution and consistent product size distribution.

4. Improved Energy Efficiency

- WC’s low friction coefficient reduces energy losses due to slippage.

- Efficient grinding with less wear means lower specific energy consumption (kWh/ton) key for cost savings in HPGR operations.

5. Protection Against Edge Wear & Spillage

- The flange area is prone to edge wear, leading to material spillage and roll damage.

- WC-reinforced flanges prevent premature edge degradation, maintaining sealing integrity and reducing material bypass.

6. Compatibility with Aggressive Materials

- Ideal for processing highly abrasive ores (e.g., iron, gold, diamond, and copper), where steel components fail quickly.

Conclusion

By integrating tungsten carbide wear plates and flanges, HPGRs achieve:

✅ Longer component lifespan (reduced replacement frequency)

✅ Higher throughput (less downtime)

✅ Better product consistency (stable grinding pressure)

✅ Lower operating costs (energy and maintenance savings)

Regular maintenance of HPGR carbide flanges is essential for extending the life of this critical piece of equipment and achieving significant cost savings. By implementing a computerized maintenance management system (CMMS), facilities management teams can effectively plan maintenance schedules, track spare parts inventory, and schedule regular inspections to prevent issues caused by high temperatures and wear. Proactive maintenance practices, performed by skilled maintenance technicians, help reduce downtime, minimize emergency maintenance, and streamline maintenance operations and maintenance work overall. This cost effective approach not only enhances equipment reliability but also optimizes long term maintenance planning.

For maximum benefits, WC components should be optimized in design (e.g., segmented plates for easy replacement) and properly installed to avoid stress concentrations.

A successful tungsten carbide HPGR wear plate solution balances material science, engineering design, and operational practicality. Prioritize high impact zones with tunsgten carbide, optimize installation for quick maintenance, and partner with experienced suppliers to ensure longevity in harsh mining environments.

Regular scheduled maintenance on HPGR flanges operating in high temperature environments is essential to keep the equipment running smoothly and protect your bottom line. While the tires (or grinding rollers) experience significant wear and tear, proper tire rotation and timely replacement of worn components similar to changing brake pads before they damage the rotor can prevent costly repairs.

A professional maintenance team that combines routine maintenance with predictive tools offers a wide range of services, from HVAC system and air conditioning checks to detailed work orders for the grinding circuit. By shifting from reactive maintenance to a proactive, cost effective program, plants can significantly reduce costs, extend equipment use life, and avoid unexpected downtime. In the long run, investing in the right types of maintenance always costs save far more than it spends.

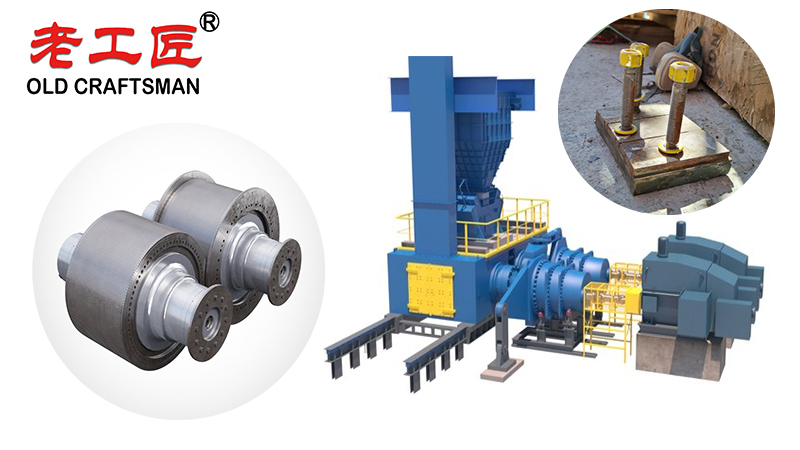

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding