Tungsten carbide (WC) wear plates significantly enhance productivity in mining operations by offering superior durability, wear resistance, and operational efficiency. Here’s how they contribute:

1. Extreme Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV 1500-2000), far outperforming steel and chromium carbide.

- Resists abrasion from rocks, ores, and slurries, reducing the frequency of replacements.

- Ideal for high-impact areas like chutes, hoppers, and conveyor systems.

2. Extended Equipment Lifespan

- Reduces downtime caused by frequent part replacements.

- Protects critical components in crushers, screens, and excavators from premature failure.

- Some WC wear plates last 10-20 times longer than steel alternatives.

3. Reduced Maintenance & Downtime

- Fewer shutdowns for repairs or replacements increase operational uptime.

- Minimizes labor costs associated with welding, patching, or swapping out worn components.

4. Improved Material Flow

- Smooth or engineered surfaces (e.g., studded or grooved designs) prevent material buildup (e.g., ore, coal).

- Reduces blockages and boosts conveyor efficiency.

5. Cost Efficiency Over Time

- Higher initial cost is offset by long-term savings from reduced replacements and labor.

- Less material waste due to consistent performance.

6. Corrosion & Impact Resistance

- Withstands harsh mining environments, including acidic/alkaline conditions and extreme temperatures.

- Maintains structural integrity even under heavy impact loads.

7. Lightweight Yet Strong

- Thinner WC plates can replace thicker steel liners, reducing weight while improving wear life.

Applications in Mining:

- Ore Chutes & Hoppers – Prevents erosion from abrasive materials.

- Excavator Buckets & Blades – Enhances digging efficiency.

- Screens & Crushers – Protects against high wear zones.

- Pump & Pipeline Components – Resists slurry erosion.

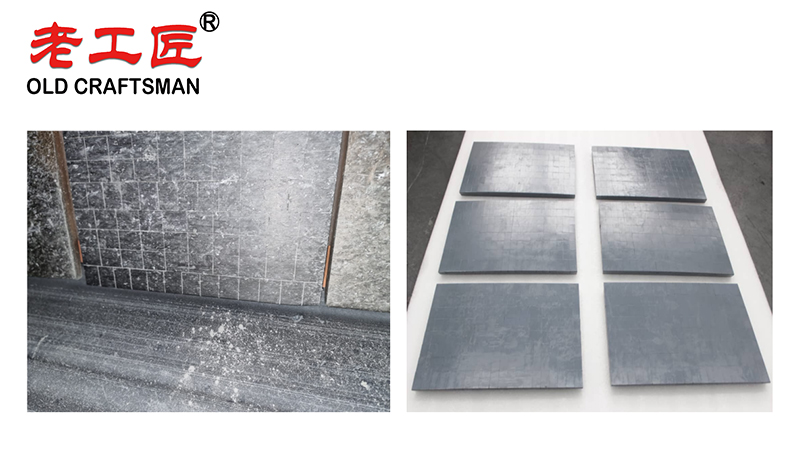

Carbide wear plates play an important role for business owners who want to increase productivity and reduce costs in demanding large-scale operations. Thanks to their outstanding abrasion resistance and ability to resist material degradation even under high temperature conditions, these plates significantly extend equipment service life, minimize unplanned downtime, and lower long-term life cycle costs. By protecting critical components in harsh work environments, they reduce waste, optimize raw material usage, and contribute to better waste management and environmental protection. Choosing a cost effective supply chain for high quality carbide wear plates ensures reliable, real-time performance improvements and sustainable profitability over the long term.

Conclusion:

By integrating tungsten carbide wear plates, mining operations achieve longer equipment life, reduced downtime, and higher throughput, leading to improved productivity and profitability.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear plates, Liners for HPGR Feed Chute and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding