In the world of mineral processing and comminution, the High Pressure Grinding Roll (HPGR) has established itself as a technology synonymous with energy efficiency, superior particle liberation, and reduced operating costs. However, the performance of an HPGR is only as good as its wear parts. While the studded rolls themselves are often the center of attention, the Carbide Cheek Plates are the unsung heroes, playing a pivotal and often underestimated role in achieving true grinding success.

What Are HPGR Carbide Cheek Plates?

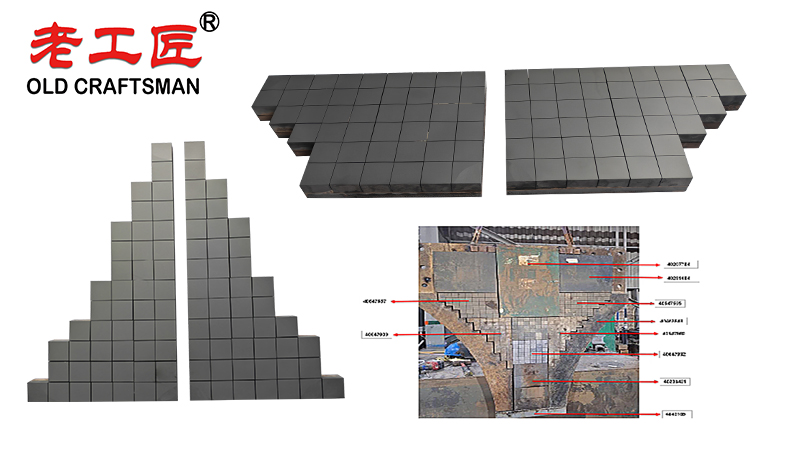

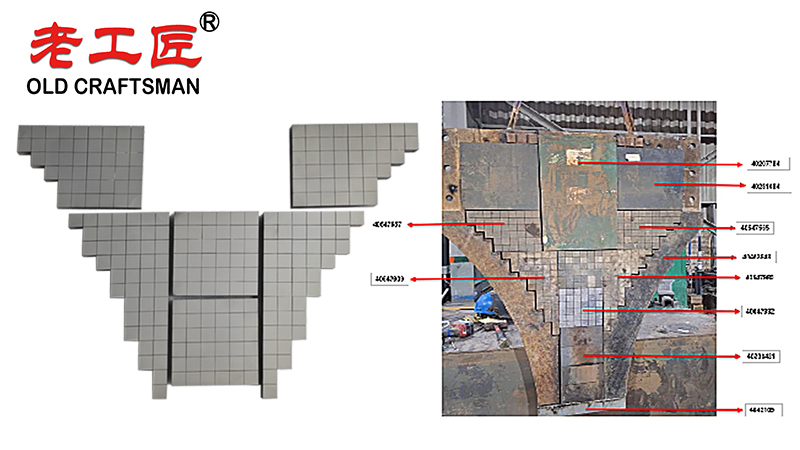

An HPGR operates by compressing a bed of ore between two counter-rotating rolls. The cheek plates, also known as side plates or end frames, are robust wear plates mounted vertically on both sides of the roll gap. Their primary function is to form a sealed “grinding chamber,” physically containing the ore feed as it is forced through the nip zone by the immense pressure of the rolls.

The “carbide” designation refers to their construction. These are not simple steel plates. They are typically fabricated from a thick steel base with strategically embedded or welded tiles of tungsten carbide. Tungsten carbide is a composite material known for its exceptional hardness, wear resistance, and compressive strength properties essential for withstanding the abrasive and high impact environment inside an HPGR.

Why Are They So Critical to Success?

The performance of the cheek plates directly impacts the entire grinding circuit’s efficiency, availability, and cost. Here’s how they are a key component:

1. Containing the Pressurized Ore Bed: The Core Function

The fundamental principle of HPGR comminution is inter-particle compression. For this to work effectively, the ore must be contained on all sides. The rolls provide pressure from the top and bottom, while the cheek plates contain it from the sides. Without effective cheek plates, ore would extrude laterally, leading to:

- Reduced Throughput: Valuable material escapes without being crushed.

- Poor Product Size Distribution: The “edge effect” results in a higher proportion of coarse, un-crushed material, defeating the purpose of the HPGR.

- Inefficient Energy Use: Energy is wasted on material that is not properly compressed.

2. Maximizing Wear Life and Minimizing Downtime

The ends of the rolls and the cheek plates themselves are subjected to extreme abrasion from the sliding bed of ore. Using standard steel plates would result in rapid wear, requiring frequent and costly replacements that cause significant production downtime.

- Carbide’s Advantage: Tungsten carbide inserts extend the service life of cheek plates by a factor of 5 to 10 times or more compared to non-hardened steel.

- Reduced Maintenance Stops: Longer wear life translates directly to longer operational campaigns between maintenance shutdowns, maximizing plant availability.

3. Protecting the HPGR’s Structural Integrity

The cheek plates act as a sacrificial barrier, protecting the much more expensive and critical main frame of the HPGR from wear. If the underlying frame is damaged, repairs are far more complex, time consuming, and expensive than simply replacing a wear plate.

4. Ensuring Consistent Operating Conditions

Worn or improperly functioning cheek plates lead to inconsistent process conditions. Fluctuations in the side seal gap can cause variations in roll pressure and power draw, making it difficult to maintain a stable and optimized grinding circuit. Consistent cheek plate geometry ensures predictable and repeatable performance.

The Consequences of Cheek Plate Failure

Ignoring the importance of robust carbide cheek plates leads directly to operational and financial losses:

- Spillage and Dust Generation: Worn seals allow fine material to escape, creating housekeeping nightmares, product loss, and potential health and safety hazards from dust.

- Increased Operating Costs: Frequent replacement of cheek plates and cleanup of spillage drives up maintenance and labor costs.

- Lower Quality Product: An inconsistent grind size can negatively impact downstream processes like flotation or leaching, ultimately affecting metal recovery rates.

Optimizing Cheek Plate Performance

Success with HPGR cheek plates isn’t just about installing them; it’s about optimizing their design and management:

- Material Selection: Choosing the correct grade and form of tungsten carbide (e.g., cast tungsten carbide inserts vs. carbide composite plates) for the specific ore’s abrasiveness is crucial.

- Design Innovation: Modern cheek plates feature advanced designs with replaceable segments, optimized carbide patterns, and engineered profiles to promote a more uniform wear pattern and extend life.

- Proactive Maintenance: Monitoring wear rates and planning replacements during scheduled shutdowns, rather than reacting to failures, is key to avoiding unplanned downtime.

Conclusion: More Than Just a Wear Part

While the rolls are the “heart” of the HPGR, the carbide cheek plates are its vital “retaining walls.” They are not a peripheral component but a fundamental element that enables the core comminution principle to function. Investing in high quality, well designed carbide cheek plates, and managing them proactively, is not an expense it is a direct investment in grinding efficiency, plant availability, and overall operational success. By securing the sides, you secure your bottom line.

In the manufacturing processes of HPGR (High Pressure Grinding Rolls) cheek plates, a wide range of advanced materials is employed to meet the specific requirements of withstanding extremely high pressures, intense abrasive wear, and in some cases high temperatures during operation. Traditionally, wear resistant stainless steels with excellent mechanical properties, high strength, and good corrosion resistance have been the material of choice, but their relatively high thermal conductivity, heavy weight, and high raw material and operational costs have driven the industry to explore high performance advanced composites. Among these, carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer composites have emerged as promising alternatives, offering outstanding wear resistance, superior strength-to-weight ratios, tailored mechanical properties, low thermal conductivity (reducing heat transfer to supporting structures), and excellent corrosion resistance in aggressive environments. By carefully selecting the matrix, reinforcement type (carbon fiber or glass fibers), and manufacturing technique, these reinforced plastic based solutions can significantly extend service life, reduce maintenance downtime, and lower overall operational costs while maintaining the structural integrity required for the final products operating under the harshest mining and cement processing conditions.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding