Composition

HPGR (High Pressure Grinding Roll) cheek plates typically combine two main materials for base plate optimal performance:

- Carbide Components:

- Usually tungsten carbide (WC) or similar hard materials

- Provides extreme wear resistance, impact resistance

- Typically comprises 70-90% of the wear surface

- Hardness range: 1200-1600 HV (Vickers hardness) high pressure & high temperatures

- Steel Base Material:

- Typically high-strength alloy steel (e.g., 4140, 4340)

- Provides structural support, high wearing and toughness

- Allows for easier machining and mounting

- Hardness range: 300-500 HB (Brinell hardness)

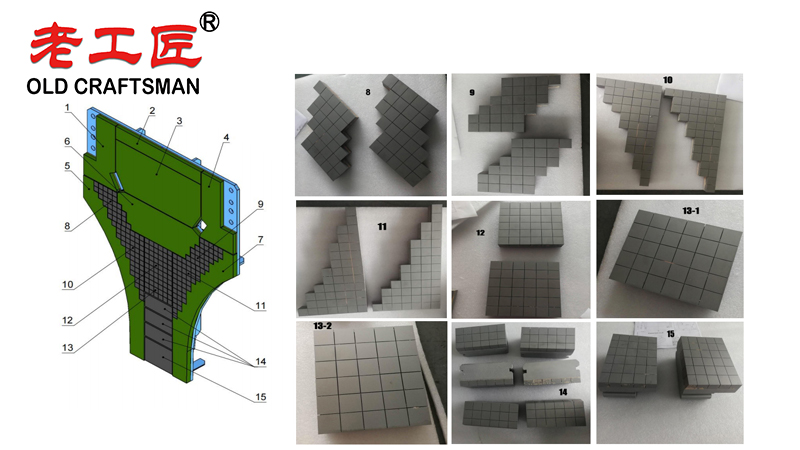

Layout Patterns

Common carbide layout patterns in HPGR cheek plates include:

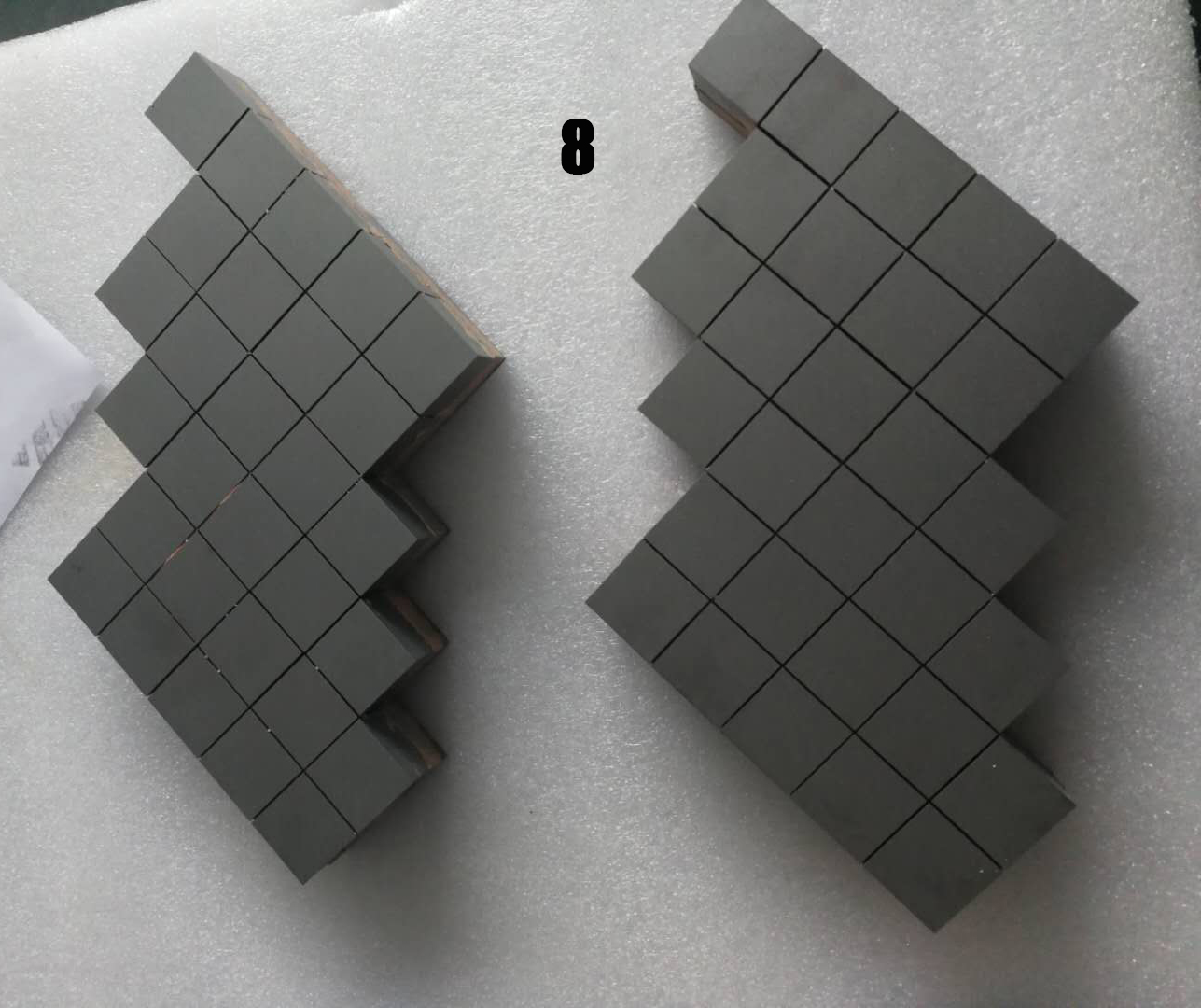

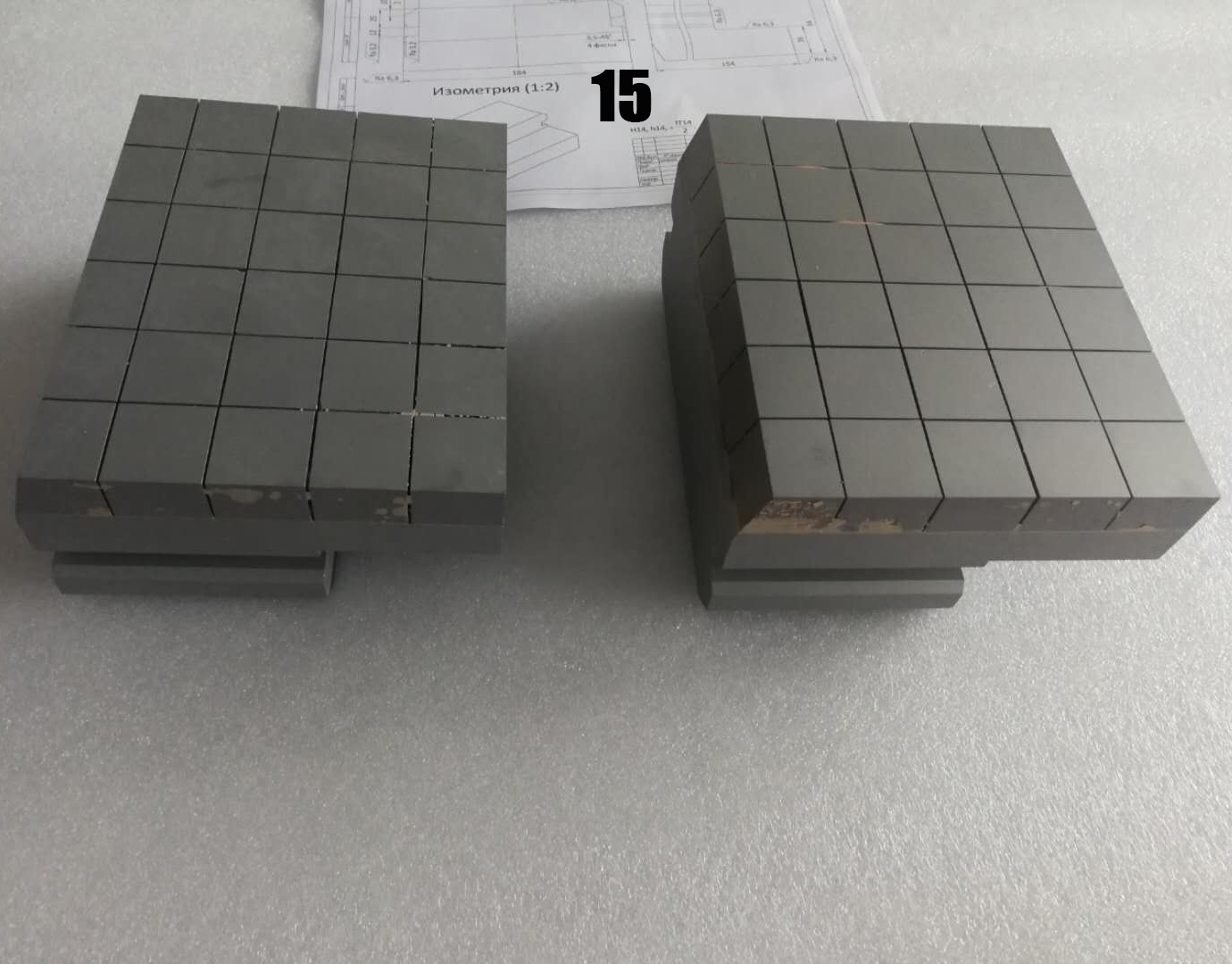

- Checkerboard Pattern:

- Alternating square or rectangular carbide inserts

- Provides uniform wear extreme wear across the surface

- Concentric Ring Pattern:

- Circular arrangement following the roll’s rotation

- Optimized for material flow characteristics

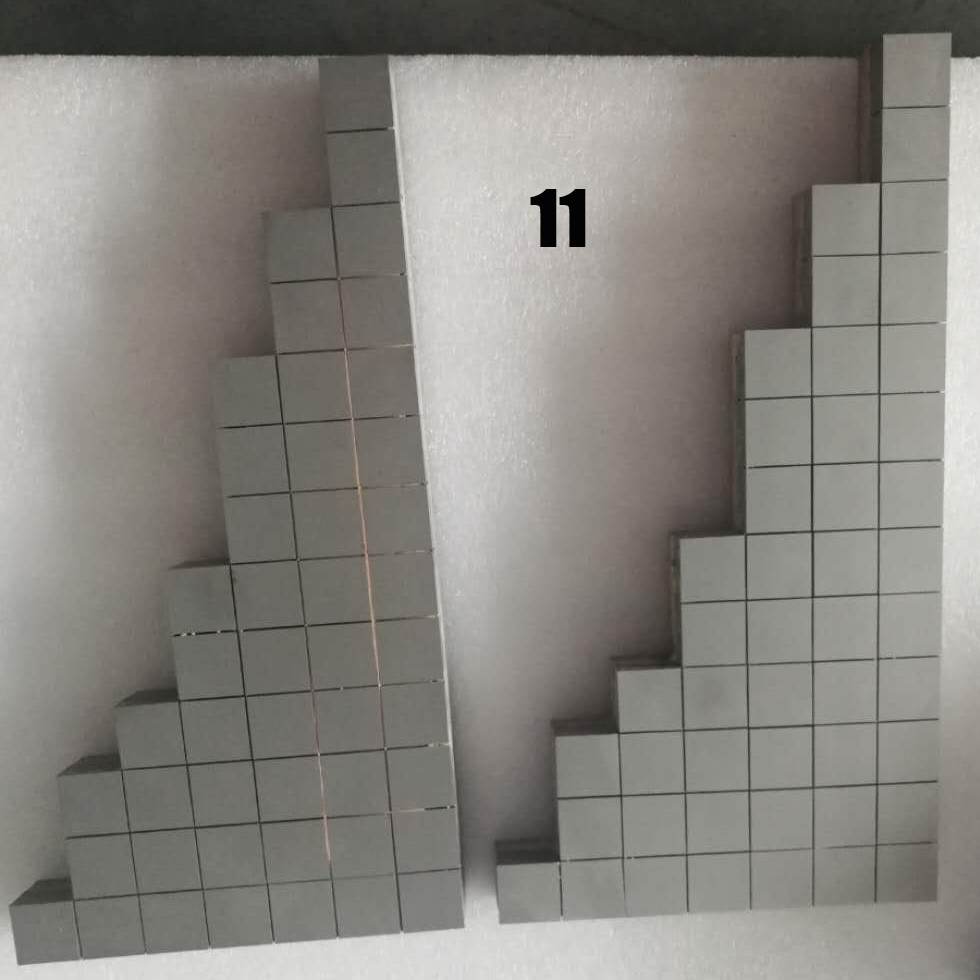

- Radial Segment Pattern:

- Wedge-shaped segments arranged radially

- Wear resistant materials good for directional wear resistance

- Custom Engineered Patterns:

- Designed for specific ore characteristics

- May combine different geometries

Manufacturing Methods

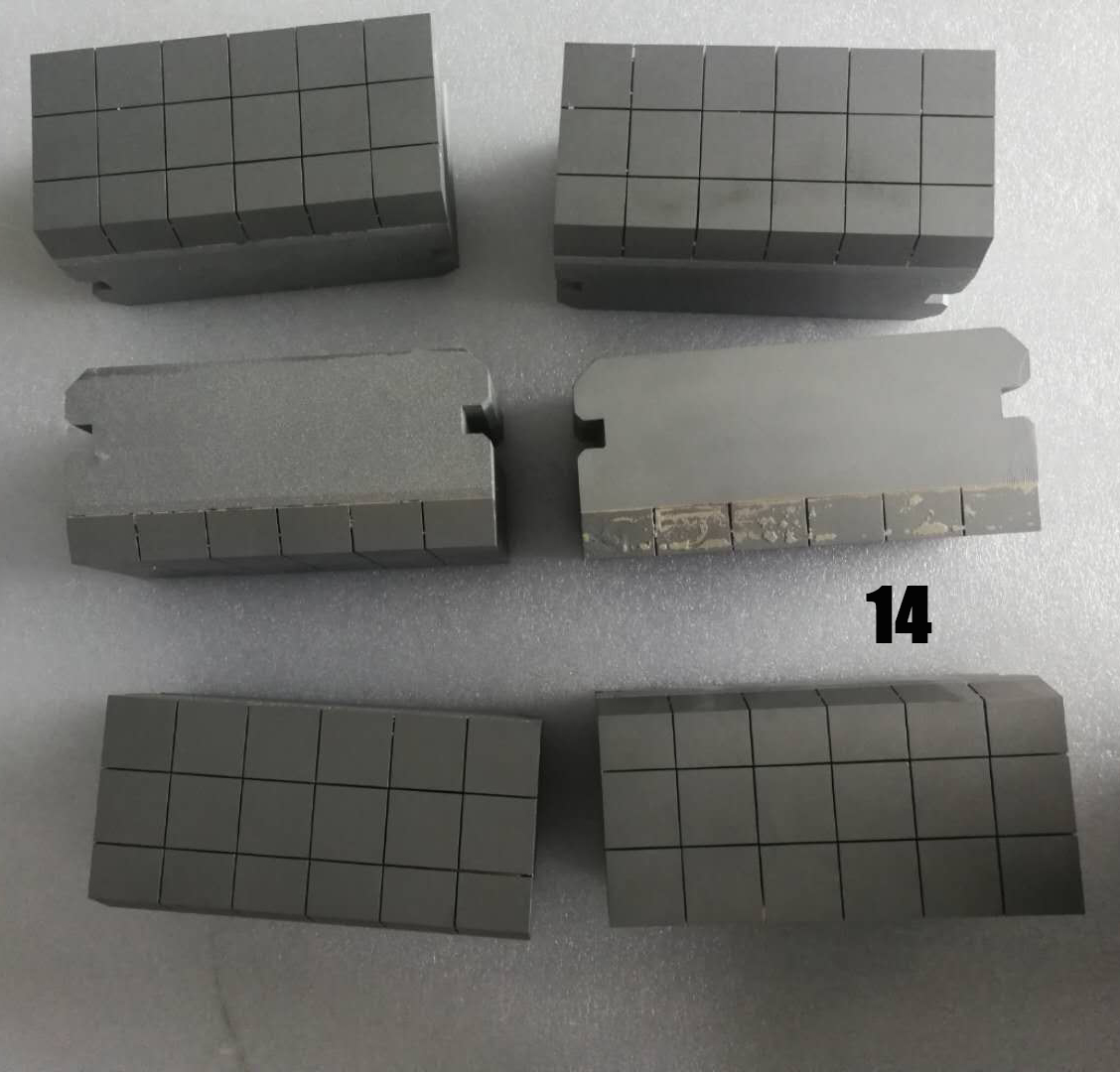

- Brazed Carbide Inserts:

- Individual carbide pieces brazed onto steel substrate

- Allows for precise placement and orientation

- Composite Casting:

- Carbide elements cast into steel matrix

- Creates strong metallurgical bond

- Mechanical Attachment:

- Carbide blocks secured with fasteners or dovetails

- Enables replacement of individual components

Key Design Considerations

- Carbide size and spacing: Balance between wear service life and material flow

- Carbide orientation: Optimized for impact and abrasion resistance

- Transition zones: Gradual changes to prevent material buildup

- Cooling provisions: Some designs incorporate cooling channels

The specific composition and layout are typically customized based on the application (ore type, operating pressure, throughput requirements) and customer’s proprietary designs.

By minimizing chute wear, improving energy efficiency, and reducing maintenance needs, tungsten carbide cheek plates in HPGRs help mining operations cut operational costs while maintaining high productivity. Their durability and performance make them a cost effective investment for modern mineral processing.

Via upgrading to carbide cheek plates, HPGRs achieve higher energy efficiency, lower operating costs, and more sustainable grinding compared to traditional steel alternatives.

High Pressure Grinding Rolls (HPGR) cheek plates are critical wear components that protect the frame of the roller press from severe abrasive wear. To ensure long service life under extreme sliding and impact conditions, these cheek plates are typically manufactured from high-strength abrasion resistant alloy steel specifically designed to resist material degradation in highly abrasive environments. These wear resistant materials belong to the family of tool steel or advanced high hardness alloy steels, with a wide range of alloying elements such as chromium, molybdenum, vanadium, tungsten, and controlled carbon content to optimize hardness, toughness, and resistance to abrasive wear. The chemical compositions are carefully balanced to achieve surface hardness values often exceeding 600 HB while maintaining sufficient core toughness. Depending on the specific applications and the abrasiveness of the processed ore, different types of wear resistant steels (including martensitic carbon steel, high chromium stainless steel, or complex alloyed tool steel grades) are selected. Production processes typically involve casting or forging followed by precise heat treatment (quenching and multiple tempering cycles) to obtain the desired microstructure. The superior performance of these cheek plates is reflected in their low coefficient of friction against the flowing material and dramatically reduced abrasive wear rates compared to conventional carbon steel or standard stainless steel, making them the preferred choice in mining and cement industries worldwide.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding