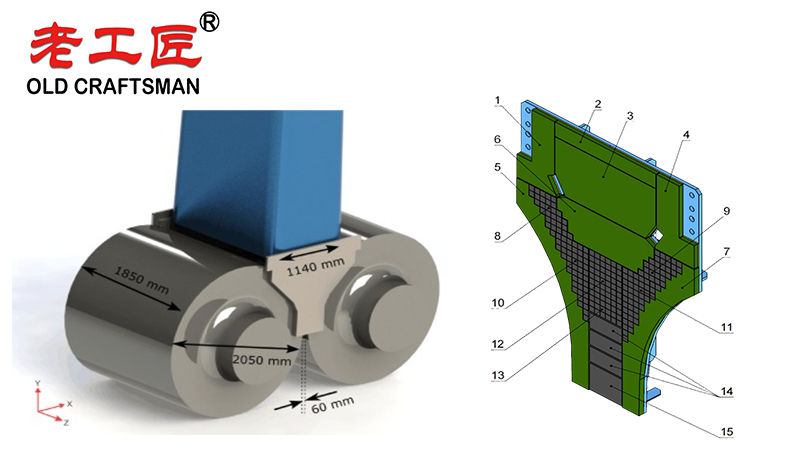

High-Pressure Grinding Rolls (HPGRs) have become a cornerstone of energy efficient comminution in the mining and aggregate industries. Their ability to achieve significant size reduction through inter-particle compression offers substantial savings in energy and downstream processing costs. However, a critical challenge in HPGR operation is wear, particularly on the cheek plates (also called end plates or side liners), which guide and contain the feed material as it enters the nip angle between the rolls.

The adoption of tungsten carbide as a material for these cheek plates is a game-changing innovation directly aimed at maximizing system throughput, availability, and overall operational efficiency during manufacturing processes.

1. The Role of Cheek Plates and the Wear Problem

Before diving into the solution, it’s crucial to understand the problem:

- Function: Cheek plates are fixed to the sides of the moving rolls. They form a pressurized chamber that ensures all feed material enters the grinding zone (the nip between the rolls) and does not simply spill out the sides. They are essential for building the high-pressure particle bed.

- The Wear Challenge: The feed material (often highly abrasive ore like iron, copper, or gold) is constantly sliding against these plates under extreme pressure. This causes severe abrasive wear, leading to:

- Loss of Profile: The plates wear down, losing their optimal shape and depth.

- Increased Clearance: A larger gap opens up between the cheek plate and the roll edge.

- Material Bypass: As the gap increases, a significant amount of feed material bypasses the grinding zone entirely. This un-pressed material reports directly to the product, increasing the proportion of coarse, unprocessed particles.

This bypass material represents a direct loss of throughput for the HPGR. The machine is using energy but not processing all the feed it receives to the target specification.

2. Why Tungsten Carbide? The Material Advantage

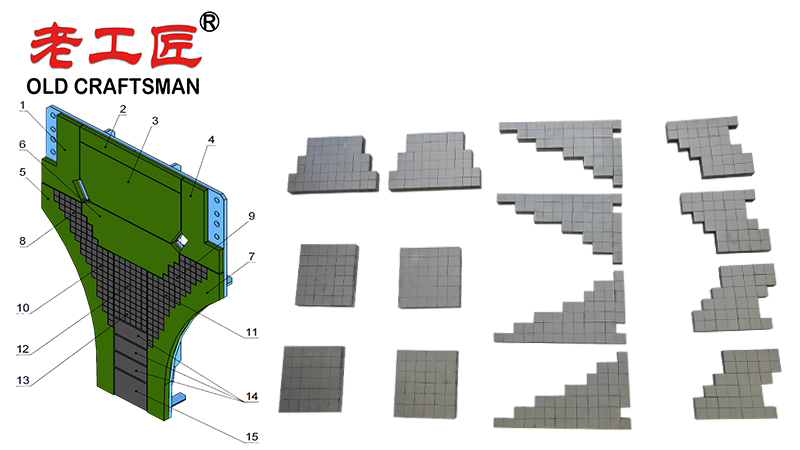

Tungsten carbide (WC) is a composite material known for its extreme hardness and wear resistance. It consists of tungsten carbide particles cemented together in a binder matrix, usually cobalt.

- Exceptional Hardness: Tungsten carbide boasts a Vickers hardness (HV) of ~1400-1800, compared to ~200-300 for hardened steel and ~500-700 for high-chrome white iron. This makes it vastly more resistant to abrasive wear.

- High Compressive Strength: It can withstand the enormous pressures (up to 5-6 N/mm²) generated in the HPGR chamber without deforming or failing.

- Long Service Life: A tungsten carbide cheek plate can last 5 to 10 times longer than a traditional martensitic steel or chrome iron plate.

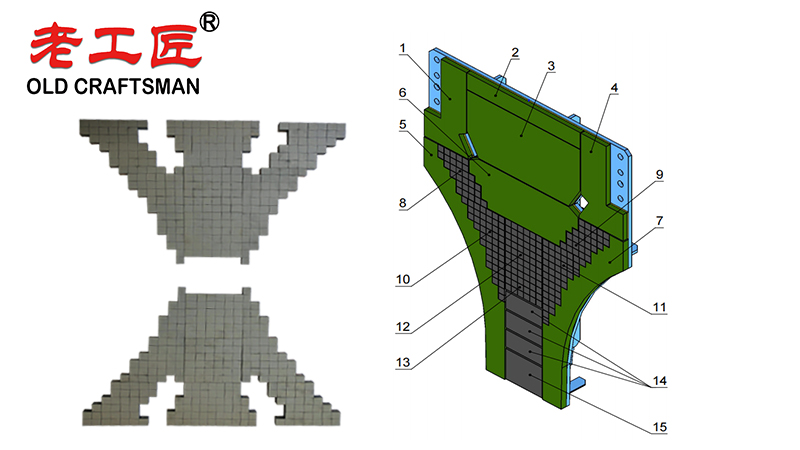

3. How Tungsten Carbide Cheek Plates Maximize Throughput

The connection between a wear resistant material and increased throughput is direct and powerful:

1. Elimination of Bypass and Consistent Performance:

The primary mechanism for throughput gain is the maintenance of a tight seal. Tungsten carbide plates wear so slowly that the critical gap between the roll and cheek plate remains minimal for their entire operational life. This ensures that virtually 100% of the feed material is forced through the grinding nip and is subjected to high pressure and high temperature comminution. There is no loss of throughput due to bypass.

2. Sustained Optimal Feed Profile:

New cheek plates have a specific engineered profile (often a series of steps or ribs) designed to grip the ore and facilitate its entry into the roll gap. With standard materials, this profile degrades quickly, reducing feeding efficiency. Tungsten carbide maintains carbon fibers this optimal profile for months, ensuring the HPGR is always being fed at its maximum designed rate.

3. Increased Operational Availability (Uptime):

Throughput is a function of both rate (tons/hour) and time (operating hours).

- Reduced Downtime for Changes: Changing worn cheek plates is a major maintenance event during production process, often requiring 24-48 hours of downtime. With a service life measured in months instead of weeks, tungsten carbide plates according to mechanical engineering drastically reduce the frequency of these changes.

- Synchronized Maintenance Scheduling: The long life of tungsten carbide plates allows plants to schedule their changes during planned maintenance shutdowns for other components (like roll studs or tires), minimizing unplanned downtime.

This increased availability means the HPGR is operating and processing tonnage for a higher percentage of the time, directly boosting overall plant throughput.

4. Consistent Product Quality:

By preventing bypass, the product size distribution remains consistent and on-spec. A consistent feed to downstream processes (like ball mills) allows them to also operate at their peak efficiency, maximizing the throughput of the entire circuit.

5. Potential for Higher Operating Pressures:

The robustness of tungsten carbide gives operators the confidence to run the HPGR at its design pressure limits without fear of accelerated cheek plate wear. This maximizes the breakage efficiency for each ton of ore passing through, corrosion resistant.

Economic Considerations: Total Cost of Ownership (TCO)

While the initial capital outlay for high quality tungsten carbide cheek plates is significantly higher (often 4-6x more expensive than steel plates), the TCO analysis almost always favors them.

- Reduced Parts Consumption: You need far fewer sets of cheek plates over a given period.

- Reduced Labor Costs: Less frequent changes mean lower maintenance labor costs.

- Increased Revenue: The value of the additional tonnage processed due to higher availability and zero bypass often dwarfs the additional material cost.

TCO = (Initial Cost + Cost of Changes + Lost Production Time) / Total Tons Processed

For a high-throughput HPGR, the cost per ton processed is almost always lower with tungsten carbide.

Summary: Key Benefits for Throughput

| Benefit | Impact on Throughput |

|---|---|

| Minimized Material Bypass | Direct Increase: Ensures 100% of feed is crushed, maximizing tons/hour. |

| Maintained Optimal Feed Profile | Sustained Rate: HPGR is consistently fed at its maximum design rate, abrasion resistance. |

| Greatly Extended Service Life | Increased Availability: Massive reduction in downtime for plate changes. |

| Synchronized Maintenance | Higher Uptime: Changes can be planned, eliminating unplanned stoppages. |

| Consistent Product Size | Downstream Efficiency: Improves performance of subsequent milling stages. |

In high-pressure grinding rolls (HPGR), cheek plates are critical components exposed to extreme abrasive conditions and occasionally high temperatures. To ensure long service life, these cheek plates are typically manufactured from high performance, abrasion resistant and corrosion resistant materials, predominantly special grades of stainless steel or advanced fibre-reinforced composites. The production process for stainless steel cheek plates involves precision casting or forging followed by specialized heat treatment to achieve excellent wear resistance, high tensile strength (often exceeding 1000 MPa in hard-faced variants), and outstanding high temperature corrosion resistance. Alternative designs utilizing reinforced plastic-based fibre-reinforced composites offer a superior strength-to-weight ratio and significantly reduced weight, which lowers inertia and energy consumption. Key material properties such as hardness, toughness, and physical properties are carefully balanced during the manufacturing process by mechanical engineers to optimize performance. Although the initial costs include premium pricing for these resistant materials (materials including high alloy stainless grades or carbon/epoxy composites with wear resistant additives), the extended maintenance intervals and increased throughput of the final products result in substantially lower total cost of ownership and superior overall high performance operation in demanding mining and cement applications.

Conclusion

The implementation of tungsten carbide cheek plates is not just a wear solution; it is a throughput optimization strategy. By mechanical properties solving the critical problem of side wall wear and material bypass, they ensure an HPGR operates at its designed capacity, consistently and reliably, for extended periods. The significant reduction in maintenance downtime directly translates to more hours of operation and more tons processed. For any operation looking to maximize the return on investment from their HPGR technology, tungsten carbide cheek plates are an essential, high value upgrade.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding