The High Pressure Grinding Roll (HPGR) has become a cornerstone of modern cement plants, renowned for its energy efficiency and potential for downstream benefits. At the heart of this machine’s performance and durability are its Tungsten Carbide Studded Edge Blocks. These components are not just wear parts; they are critical technology enablers that directly impact the bottom line of cement production.

The Role of the HPGR in Cement Production

Before diving into the edge blocks, it’s important to understand the HPGR’s function. An HPGR is a comminution (size reduction) machine that operates on the principle of inter particle compression. It consists of two counter rotating rolls:

- One roll is fixed in position.

- The other is movable, pressed against the material by a hydraulic system with extremely high pressure (e.g., 4-6 N/mm²).

As the cement clinker (often mixed with additives) is fed between the rolls, it is crushed into a compacted cake or flakes. This process is significantly more energy efficient than traditional ball mills for achieving a similar size reduction.

What are the Edge Blocks and Why are They Critical?

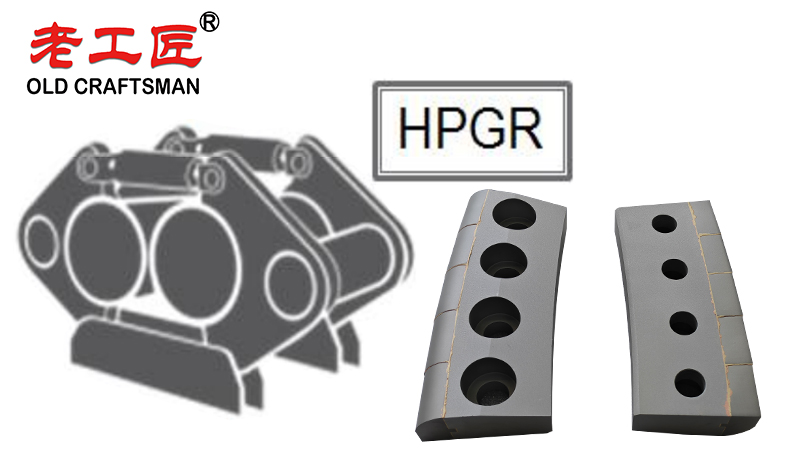

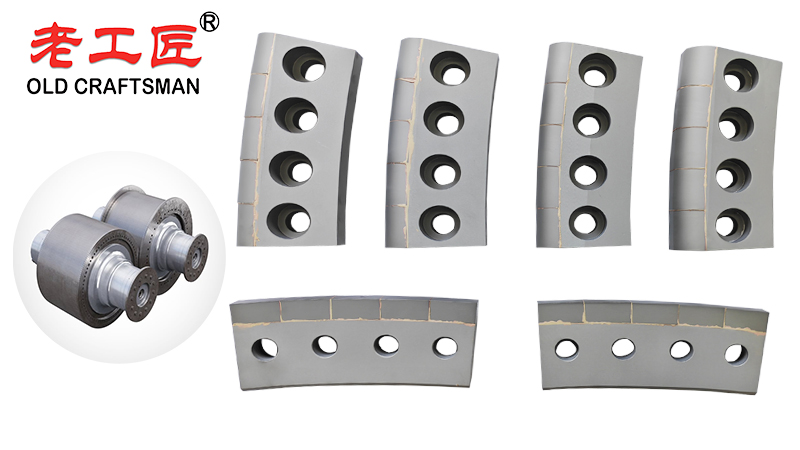

The rolls of an HPGR are not smooth. Their surface is covered with studs made of ultra-hard Tungsten Carbide (WC). These studs are pressed into precisely machined holes on edge blocks, which are then bolted to the roll’s core.

The Edge Problem: Without a solution, fine material would simply slide out the sides of the rolls without being compressed, a phenomenon known as “edge leakage.” This represents a massive loss of efficiency, throughput, and control.

The Edge Block Solution: The edge blocks are specially designed segments placed at the ends of each roll. They create a labyrinth seal and act as a physical barrier, preventing the feed material from escaping sideways without being processed.

The Tungsten Carbide Studs: The studs on these blocks are the first point of contact with the abrasive clinker feed. Tungsten Carbide is chosen because of its exceptional properties:

- Extreme Hardness: Near-diamond hardness (~90 HRA) resists abrasive wear from clinker minerals.

- High Compressive Strength: Can withstand the immense pressures without fracturing.

- Good Fracture Toughness: A balance that prevents it from being too brittle under impact.

How Tungsten Carbide Edge Blocks Drive Efficiency

The synergy of the HPGR design and the robust edge blocks translates into direct operational and economic benefits:

1. Maximized Throughput and Yield:

- By effectively sealing the grinding zone, edge blocks ensure that 100% of the feed material is forced through the nip (the gap between the rolls) and is subjected to the high pressure grinding action.

- This eliminates product loss, maximizes the machine’s capacity, and ensures a consistent, high yield of finished product.

2. Dramatic Energy Savings:

- HPGRs are inherently more energy efficient than ball mills, often reducing energy consumption for comminution by 20-50%.

- Efficient edge blocks are fundamental to this. If material leaks, energy is wasted moving unprocessed material. By containing the pressure, every kilowatt-hour is used to crush clinker, not push it sideways.

- This is the single largest efficiency driver, directly reducing electricity costs, which are a major expense in cement production.

3. Improved Grinding Efficiency and Downstream Benefits:

- The high-pressure process creates micro-cracks within the particles of the compacted “cake” it produces.

- This makes the material weaker and more amenable to further grinding in the subsequent ball mill or vertical roller mill.

- The downstream mill can therefore operate more efficiently, at a higher throughput, or produce a finer product with the same energy input. This is known as the “work index reduction” benefit.

4. Extended Operational Life and Reduced Downtime:

- Tungsten Carbide studs on the edge blocks have a vastly longer service life than conventional steel would in this application.

- While they are a consumable item, their robustness means:

- Longer intervals between maintenance shutdowns for stud replacement or roll rebuilding.

- Reduced inventory of spare parts and less labor for changes.

- Higher availability of the HPGR unit, leading to more consistent production.

5. Enhanced Process Stability and Control:

- Effective edge sealing maintains a stable bed of material between the rolls, which is crucial for smooth operation.

- It prevents fluctuations in power draw and pressure, leading to a more consistent product size distribution and easier process control for operators.

The Economic Impact: A Summary

| Efficiency Factor | Economic Benefit |

|---|---|

| Energy Consumption | Direct reduction of 20-50% in grinding circuit power costs. |

| Throughput & Yield | Maximized production output from the circuit, no loss from edge leakage. |

| Wear Life | Reduced maintenance costs, less downtime, lower spare parts inventory. |

| Downstream Efficiency | Higher throughput in ball mills or improved product fineness. |

In cement manufacturing, clinker production is the most energy intensive stage, traditionally relying on fossil fuels to power the cement kiln at high temperatures above 1,450 °C. The production process begins with raw materials such as limestone and clay, which are ground and fed into the kiln, where intense thermal energy triggers chemical reactions to form calcium silicate compounds. These reactions also release significant carbon dioxide, making clinker production responsible for the majority of carbon emissions in the industry. To create a more cost effective and sustainable type of cement for long term use, manufacturers are exploring the HPGR Edge Block technology, which reduces energy consumption during grinding. Additionally, integrating renewable energy sources into the process can further lower emissions and operational costs.

Conclusion

Tungsten Carbide Edge Blocks are far more than simple wear protection components. They are a critical enabling technology that ensures the HPGR operates at its designed potential. By effectively sealing the high pressure grinding zone, they directly convert mechanical energy into efficient particle size reduction, unlocking the massive energy savings, increased throughput, and operational stability that make the HPGR an indispensable asset in the modern, cost conscious, and sustainability driven cement industry. Their performance is a key determinant in the overall efficiency and profitability of the cement grinding circuit.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding