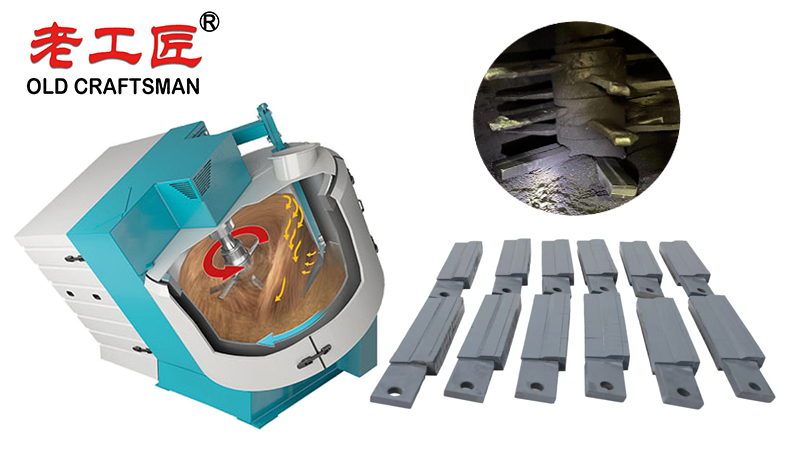

Upgrading mixer blades to tungsten carbide (WC) can significantly improve longevity, especially in high wear applications like abrasive slurry mixing, powder processing, or corrosive environments. Here’s how tungsten carbide enhances mixer performance and key considerations for implementation:

Benefits of Tungsten Carbide Blades

- Exceptional Wear Resistance

- Tungsten carbide is 5-7x harder than steel, drastically reducing erosion from abrasive particles.

- Ideal for mixing ceramics, minerals, or filled polymers.

- Corrosion Resistance

- Performs well in acidic/alkaline environments where stainless steel may degrade.

- Suitable for chemical, pharmaceutical, and wastewater applications.

- Extended Service Life

- Reduces downtime for blade replacements, lowering maintenance costs.

- Can last 10x longer than standard steel blades in harsh conditions.

- Improved Mixing Efficiency

- Maintains sharp edges longer, ensuring consistent mixing quality over time.

- Reduces power consumption by minimizing blade wear-induced inefficiencies.

Key Considerations for Upgrade

- Compatibility

- Verify shaft attachment (bolted, welded, or clamped) and dimensional fit.

- Ensure the mixer motor can handle potential weight increases (WC is denser than steel).

- Cost vs. ROI

- Tungsten carbide blades are more expensive upfront but offer long-term savings.

- Justify cost by calculating reduced replacement frequency and downtime.

- Application-Specific Design

- Slurry Mixing: Opt for solid WC or WC-coated blades to combat abrasion.

- High-Speed Mixing: Use impact resistant grades (e.g., WC with cobalt binder).

- Food/Pharma: Ensure coatings meet FDA/compliance standards.

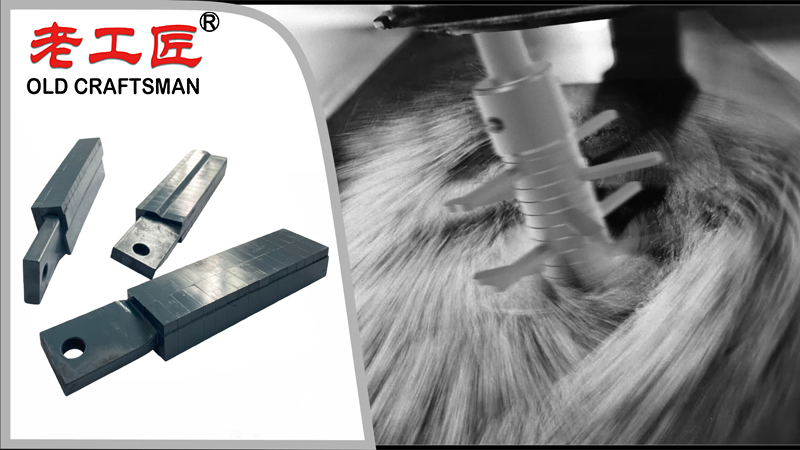

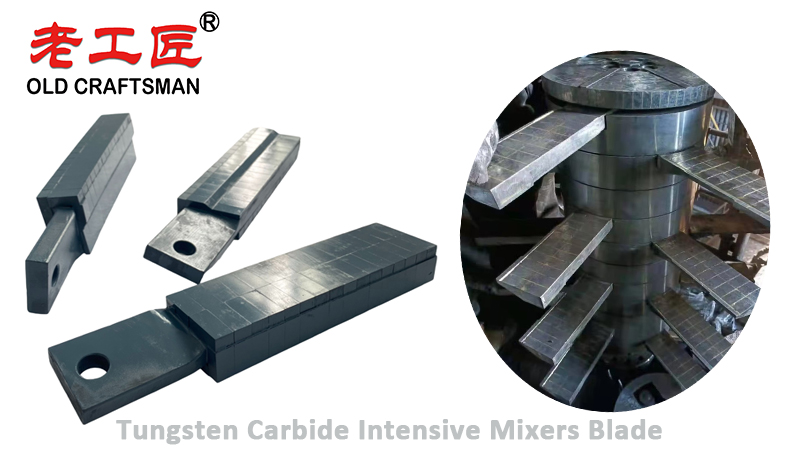

- Manufacturing Methods

- Brazed WC tips: Cost-effective for edge reinforcement.

- Full WC blades: Maximum durability for extreme conditions.

- HVOF Spray Coating: Alternative for large or complex blades.

Potential Challenges

- Brittleness: Tungsten carbide can chip under high-impact loads (e.g., mixing hard aggregates).

- Solution: Use tougher WC grades (e.g., fine-grained WC-Co) or hybrid steel-WC designs.

- Machining Difficulty: WC blades require diamond grinding for reshaping.

- Solution: Partner with specialized manufacturers.

Implementation Steps

- Evaluate Current Wear Patterns – Identify erosion points to optimize blade design.

- Select Appropriate WC Grade – Match binder content (e.g., 6-12% cobalt) to application needs.

- Prototype Testing – Run trials to confirm performance vs. steel blades.

- Supplier Collaboration – Work with experienced WC fabricators for custom geometries.

High-quality tool steel is the preferred material for carbide-intensive mixers and high performance cutting tools operating in demanding mixing processes. These steel alloys, carefully selected for their superior mechanical properties, undergo specialized heat treatment to achieve exceptional hardness, heat resistance, and toughness even at high temperatures. The optimized composition of alloying elements ensures outstanding abrasion resistance and the ability to resist material wear in highly abrasive and corrosive environments. As a result, the cutting edge of the mixer blades maintains long lasting sharpness and durability, significantly extending service life and delivering reliable performance in the most challenging industrial conditions.

Conclusion

Upgrading to tungsten carbide mixer blades is a proven solution for extending equipment life in abrasive or corrosive environments. While the initial investment is higher, the reduction in maintenance and downtime often delivers a strong ROI within 12-24 months. For optimal results, tailor the blade material and design to your specific mixing process.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding