Zhuzhou Old Craftsman Precision Alloy Co., Ltd. produce carbide vacuum brazed wear parts, like wear liners, hammers and wear spare parts for crushers, mixing blades, conveyor belt scrapers, etc. for mining and crushing. The performance is tens of times longer than the present material, these products can help users save lots of time and money on the shutdown. If you have any wear problems of your products, welcome to contact us for free customized design.

We specialize in high quality, tungsten carbide based products tailored to meet the rigorous demands of mining operations. Our featured exhibits include:

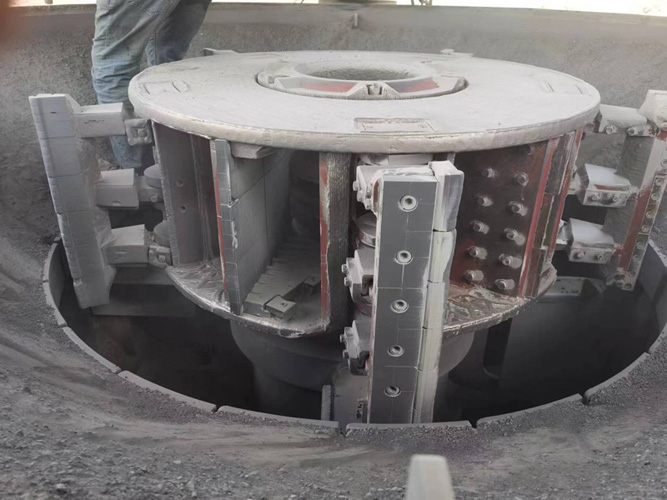

1.Crusher Tungsten Carbide Hammers

Engineered with superior wear resistance, our hard alloy hammers extend service life by up to 50% compared to traditional materials. Their exceptional toughness reduces downtime and maintenance costs, ensuring uninterrupted crushing performance even under the harshest conditions.

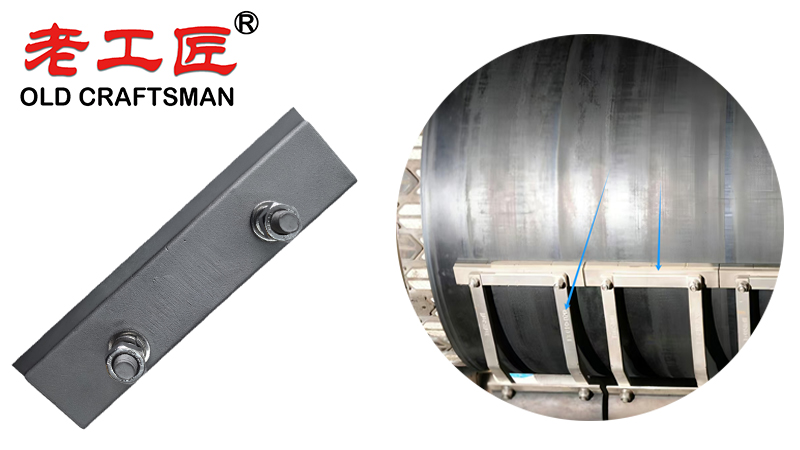

2.Conveyor Belt Hard Alloy Scrapers

Our scrapers are designed to maintain conveyor efficiency by effectively removing debris while resisting abrasion. Made from premium hard alloys, they offer unmatched durability, minimizing replacement frequency and optimizing material flow in your operations.

3.Chute Tungsten Carbide Wear Liners

These liners provide a robust shield against abrasive wear and impact, protecting chutes from degradation. Their high hardness and corrosion resistance ensure prolonged lifespan, reducing operational interruptions and enhancing throughput in material handling systems.

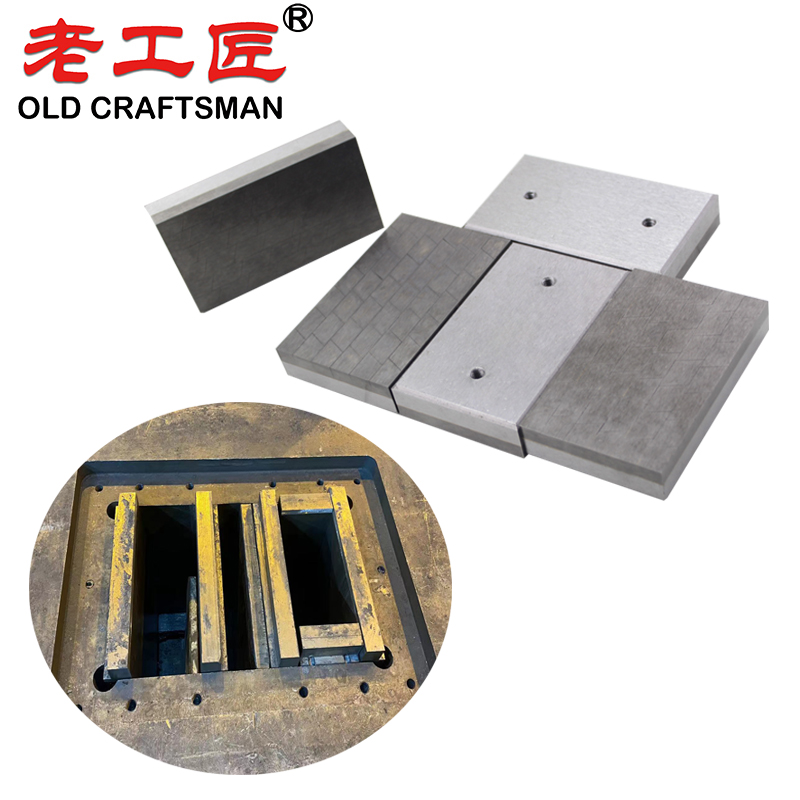

4.Refractory Brick Hard Alloy Molds

Our molds deliver precision and resilience in producing refractory bricks. The hard alloy composition withstands extreme temperatures and repetitive use, guaranteeing consistent brick quality and lowering production costs over time.

5.Concrete Hard Alloy Mixer Blades

Built for heavy duty mixing, these blades resist wear from abrasive aggregates, offering exceptional longevity and uniform mixing performance. Their strength translates to reduced blade replacements and improved productivity in concrete preparation.

What sets our products apart is our commitment to innovation and quality. Each item is crafted using advanced hard alloy technology, providing superior resistance to wear, impact, and corrosion key challenges in mining environments. By integrating these solutions, your operations can achieve greater reliability, lower maintenance expenses, and enhanced output, all while contributing to sustainable practices through reduced material waste.

We warmly invite you to visit Booth 3-D14 during the exhibition to explore these products firsthand. Our team will be on-site to demonstrate their applications, discuss your specific needs, and explore potential collaborations. The exhibition date from April 22th to 25th. This is a prime opportunity to connect with industry leaders, discover innovative technologies, and see how Zhuzhou Old Craftsman Precision Alloy Co., Ltd. can support your success.

Tungsten carbide is widely recognized as one of the most effective wear resistant materials for high temperature, abrasion resistant applications in demanding industrial applications. Thanks to its exceptional high strength, excellent mechanical properties, and extremely low coefficient of friction, tungsten carbide provides a superior tungsten carbide wear solution that significantly outperforms traditional materials like stainless steel in environments subjected to severe abrasive wear. Its outstanding resistance to both wear and corrosion resistant conditions ensures long term durability even under extreme mechanical and thermal stress. Various manufacturing processes, including brazing, welding, and plasma spraying, allow tungsten carbide to be applied as coatings, inserts, or solid components in specific applications such as mining tools, cutting blades, pump seals, and valve components. Although the initial investment is higher than many alternatives, its exceptional performance and extended service life make tungsten carbide a highly cost effective choice for virtually every type of wear, including abrasion, erosion, and impact, making it an indispensable material in modern high-performance engineering.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding