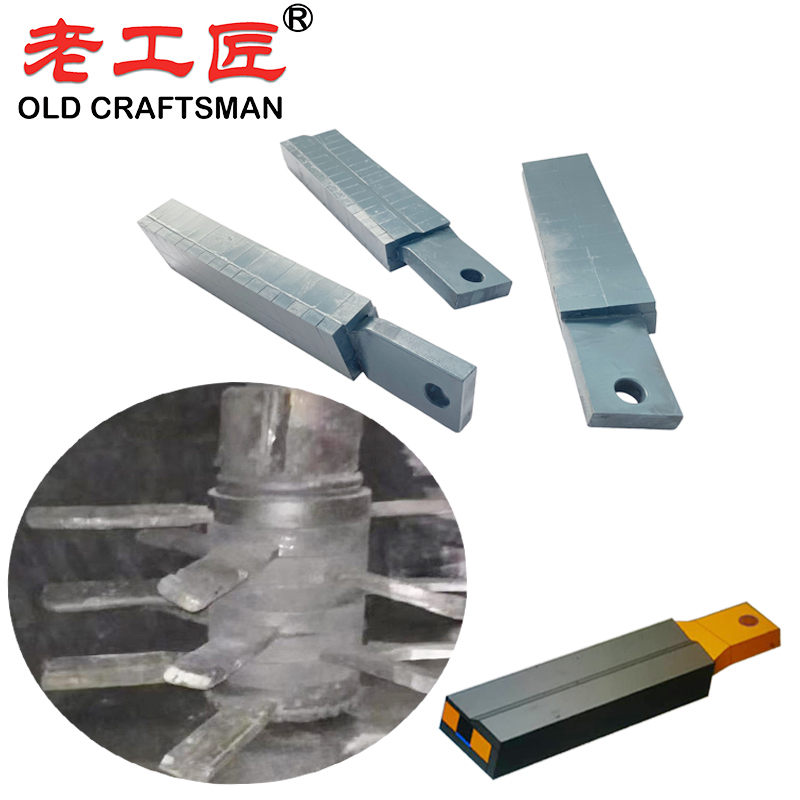

Tungsten carbide paddles are recommended for concrete mixers due to their exceptional durability and performance. Here’s why:

1.Superior Hardness and Wear Resistance: Tungsten carbide is one of the hardest materials available, making paddles highly resistant to abrasion and wear from mixing abrasive concrete components like sand, gravel, and cement. This extends the paddle’s lifespan compared to steel or other materials.

2.Enhanced Mixing Efficiency: The robust nature of tungsten carbide allows paddles to maintain their shape and edge, ensuring consistent mixing action. This results in a more uniform concrete mix, reducing clumps and improving quality.

3.Improved Concrete Properties: Research shows that incorporating tungsten carbide in concrete composites can enhance mechanical properties, such as increasing compressive strength by 17% and flexural strength by 39% at 4% by cement weight. While this refers to tungsten carbide as an admixture, similar benefits may translate to paddle performance due to reduced material degradation during mixing.

4.Reduced Maintenance and Downtime: Tungsten carbide paddles resist damage from tough aggregates, minimizing the need for frequent replacements or repairs. This reduces downtime on construction sites, saving time and labor costs.

5.Cost-Effectiveness Over Time: Although tungsten carbide paddles may have a higher upfront cost, their longevity and performance lead to lower cost per use compared to standard steel paddles, which wear out faster.

Note: The recommendation depends on the specific mixer and concrete type. For less abrasive mixes or smaller batches, standard paddles might suffice. Always match the paddle to the material and mixing volume for optimal results.

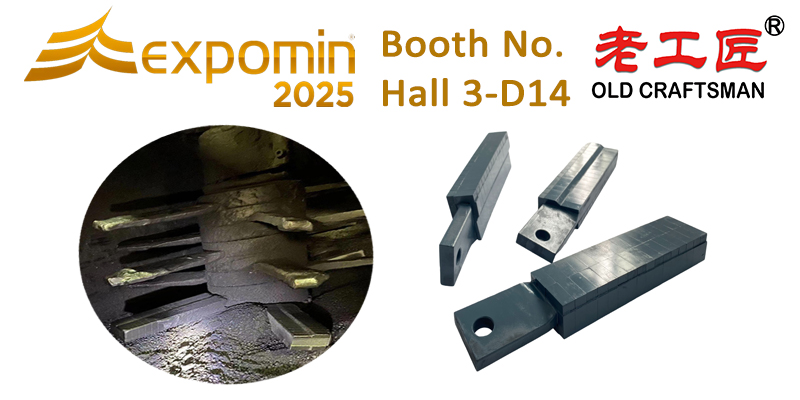

Looking Forward to EXPOMIN 2025

EXPOMIN 2025 is a fantastic opportunity for us to connect with the mining community, share our expertise, and explore new partnerships. We are particularly excited to engage with clients and partners in Chile, a country at the forefront of the global mining industry. Join us in Santiago to discover how ZZ OLD CRAFTSMAN can help you achieve greater efficiency, sustainability, and profitability in your mining operations.

Stay tuned for more updates as we prepare for EXPOMIN 2025. Follow us on ZZ OLD CRAFTSMAN Social Media Links, for the latest news and insights from our team. We can’t wait to see you in Santiago!

In large-scale, long-term construction projects, high-strength ready-mix concrete with exceptional compression strength and high density is essential for durable infrastructure. To achieve superior performance, carbide-intensive mixers equipped with stainless steel blades coated with tungsten carbide on the cutting edge are widely used in the industry, as tungsten carbide is a critical mineral renowned for its extreme hardness and resistance to high temperatures—making it ideal not only as a cutting tool but also for wear-resistant components like tungsten carbide rings. Companies like Rio Tinto, a major producer of critical minerals including those needed for rare earth elements and tungsten, play a key role in supplying the building materials value chain while increasingly focusing on sustainable practices and supporting local communities near their operations. (Wikipedia, the free encyclopedia, lists ready-mix concrete as one of the most important modern construction materials, with ongoing research into mineral additives to further enhance long-term performance.)

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding