Here is a detailed breakdown of the key features of High Performance HPGR (High Pressure Grinding Roll) tungsten carbide flanges, explaining why they are critical components in this demanding application.

Executive Summary

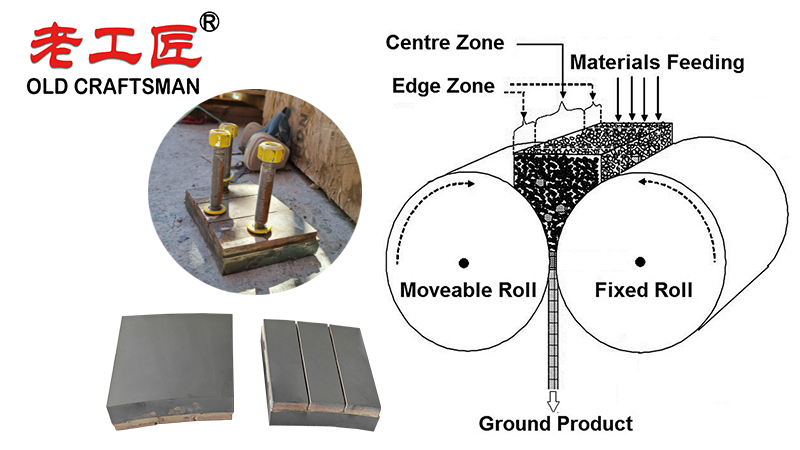

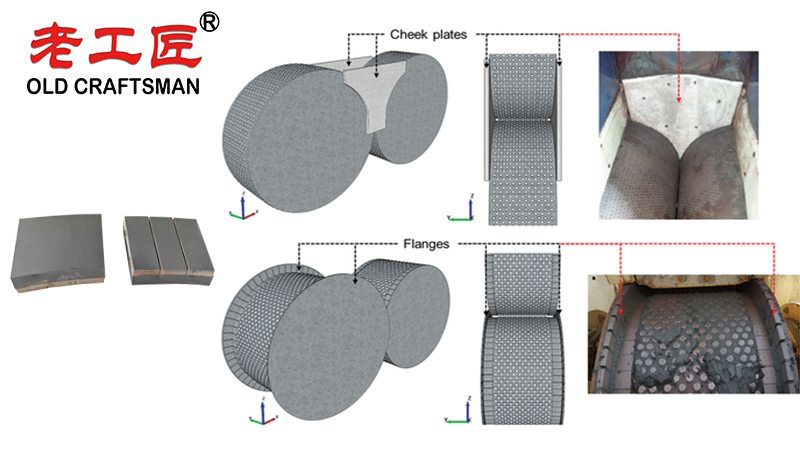

HPGR flanges are the outer wear parts that make up the body of the grinding rolls. They are subject to extreme pressure, abrasion, and impact. Tungsten carbide is the material of choice for high performance applications due to its exceptional hardness and wear resistance. The key features revolve around maximizing service life, reliability, and cost effectiveness in a brutally harsh environment.

Key Features of High-Performance HPGR Tungsten Carbide Flanges

1. Exceptional Wear Resistance & Hardness

- Feature: Manufactured from premium grade, fine grained tungsten carbide (WC) with a cobalt (Co) or nickel (Ni) binder. They typically boast a Vickers hardness (HV) of 1300-1600 or more.

- Why it Matters: This is the primary reason for using tungsten carbide. The extreme hardness allows the flanges to withstand the constant abrasive wear caused by grinding hard, abrasive ore (like iron, copper, gold, or diamond). This directly translates to a significantly longer operational life compared to steel flanges, reducing downtime and replacement costs.

2. High Compressive Strength

- Feature: Tungsten carbide has an extremely high compressive strength, often exceeding 6000 MPa.

- Why it Matters: HPGRs operate by applying immense pressure (up to several hundred MPa) to a bed of ore particles. The flanges must not crack or deform under this colossal load. High compressive strength ensures the structural integrity of the roll, maintaining the precise gap and pressure profile necessary for efficient grinding.

3. Superior Fracture Toughness

- Feature: While very hard, pure tungsten carbide can be brittle. High performance flanges are engineered with a carefully balanced carbide grain size and binder content to optimize fracture toughness.

- Why it Matters: The grinding process is not purely abrasive; it also involves impact from large, hard feed material or potential tramp metal. Improved fracture toughness prevents the flange from chipping, spalling, or catastrophic failure upon impact, ensuring reliability and safety.

4. Optimized Microstructure and Composition

- Feature: This is a critical engineering aspect. Performance is tailored by:

- Grain Size: Fine grained carbide offers better wear resistance and hardness. Ultra fine grades are used for the most abrasive ores.

- Binder Content: A lower cobalt content increases hardness but reduces toughness. A higher content does the opposite. The recipe is optimized for the specific ore type and operating conditions.

- Why it Matters: There is no “one-size-fits-all” solution. A flange designed for abrasive but non-impactful iron ore will have a different composition than one for a ore body known for its impact. This customization is key to maximum performance.

5. Precise Dimensional Accuracy and Geometry

- Feature: High performance flanges are manufactured to very tight tolerances through precision grinding (after a sintering process).

- Why it Matters: The flanges are assembled onto a central roll shaft to form a continuous roll surface. Any dimensional inaccuracies can lead to:

- Improper fitting and insecure mounting.

- An uneven roll surface, causing vibration, inefficient grinding, and uneven wear.

- Points of high stress that can initiate cracks.

6. Advanced Bonding/Assembly Technology

- Feature: The tungsten carbide flange is not a monolithic piece of carbide (which would be too expensive and brittle). It is a carbide ring that is securely bonded to a tough, ductile steel core or hub.

- Why it Matters: This hybrid design combines the best of both materials: the wear resistance of carbide on the outside and the shock absorbing strength and ease of mounting of steel on the inside. The quality of this bond is paramount; a failure here would cause the carbide ring to detach.

7. Customized Profile and Design

- Feature: Flanges can be designed with specific profiles (e.g., straight, stepped, or crowned) and with features like anti-spin mechanisms (e.g., keyways or splines).

- Why it Matters: The profile helps control the flow of material at the edges of the roll, minimizing edge wear and optimizing the particle bed pressure distribution. Anti-spin features prevent the flange from rotating independently on the shaft, which would destroy the assembly.

8. Consistent Quality and Reliability

- Feature: Reputable manufacturers employ rigorous Quality Control (QC) processes, including ultrasonic testing, density checks, and hardness testing on every piece.

- Why it Matters: In an HPGR, a single failing component can cause extensive secondary damage to the opposing roll, the frame, and the drive system. Consistent, reliable flanges are non-negotiable for protecting the multi-million dollar investment of the entire HPGR unit.

Summary Table: Problem vs. Feature Solution

| Problem in HPGR Operation | Key Feature of Tungsten Carbide Flange | Benefit |

|---|---|---|

| Extreme Abrasive Wear | Exceptional Hardness & Wear Resistance | Dramatically extended service life, lower cost per ton |

| Immense Operating Pressure | High Compressive Strength | Resists deformation, maintains grinding efficiency |

| Impact from Feed Material | Superior Fracture Toughness | Resists chipping and catastrophic failure |

| Specific Ore Characteristics | Optimized Microstructure | Customized performance for maximum ROI |

| Vibration & Uneven Wear | Precise Dimensional Accuracy | Smooth operation, consistent grind, even wear |

| Shock Loads & Mounting | Advanced Steel-Carbide Bonding | Secure attachment, absorbs operational stresses |

| Material Flow at Edges | Customized Profile Design | Optimized performance and reduced edge wear |

| Component Failure Risk | Consistent Manufacturing Quality | Protects the entire HPGR system from damage |

In conclusion, high erformance HPGR tungsten carbide flanges are not simple pieces of hard metal; they are highly engineered components where material science, mechanical design, and precise manufacturing converge to solve the extreme challenges of high pressure grinding.

High Pressure Grinding Rolls (HPGR) with wide range flanges are widely used in the mining and cement industries for energy-efficient comminution of hard ores and clinker. The rolls are typically protected by wear resistant surfaces made of cemented carbide (tungsten carbide) studs or segments that are shrink fitted or brazed onto high temperature resistant stainless steel or tool steel bases. These cemented carbide surfaces, often featuring a tungsten carbide ring design around the tire edges, provide exceptional service life even when processing highly abrasive materials such as hardened steel scrap, cast iron, or mild steel inclusions. Thanks to their extremely high Rockwell hardness (typically 85–92 HRA) and superior resistance to plastic deformation and cut edges, HPGR rolls clad with cemented carbide significantly outperform conventional carbon steel or heat treated tool steel rolls in high performance applications throughout the United States and worldwide. This combination of advanced materials and precise heat treatment ensures minimal downtime and maximum productivity in the most demanding crushing environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding