1. “Refractory production status and challenges: the key role of mixer blade technology”

Refractory materials are critical in industries like metallurgy, glass, cement, and ceramics, excelling under extreme heat, pressure, and corrosive conditions. However, traditional production methods and blade designs struggle with complex raw material mixing, uneven blending, and poor wear resistance—limiting efficiency and quality.

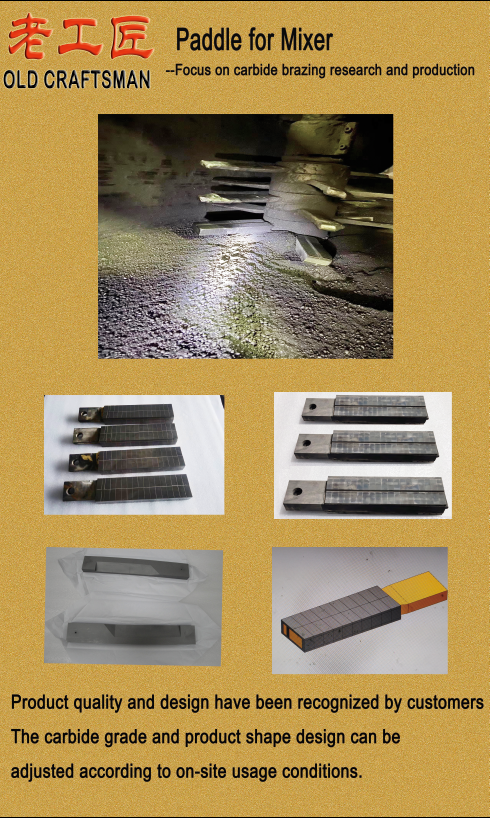

The mixer blade is a vital component directly impacting refractory performance. Conventional blades fail in high-temperature, abrasive environments.

ZZ Craftsman’s vacuum-brazed carbide-steel mixer blades solve this. Tungsten carbide delivers superior wear resistance and thermal stability, while steel provides toughness and strength. Vacuum brazing perfectly bonds them, eliminating weaknesses and enhancing durability, mixing uniformity, and service life—significantly boosting production efficiency and refractory quality.

2. Analysis of vacuum brazing technology of cemented carbide and steel: why it has become the new favorite in the refractory materials industry

With industrial advancements and rising market demands, the refractory industry is embracing vacuum-brazed carbide-steel mixer blades as a breakthrough innovation. This technology combines cemented carbide’s extreme hardness and wear resistance with steel’s toughness and strength, creating blades that excel in high-temperature, abrasive mixing environments—delivering superior durability, uniformity, and extended service life.

Zhuzhou Old Craftsman optimizes performance through three critical factors:

*Carbide Grade Selection: Refractory raw materials (hexamine, graphite, resin, alumina, magnesite) reach 9 Mohs hardness. Selecting the right carbide grade prevents rapid wear and ensures longevity.

**Vacuum Brazing vs. High-Frequency: While high-frequency brazing is cheaper, it causes cracking, quality loss, and carbide detachment. Vacuum brazing eliminates oxidation and internal stress, ensuring zero fallout and consistent performance, despite higher cost and complexity.

***Innovative Design: Minor shape adjustments—based on customer feedback—have doubled blade lifespan, proving that smart design amplifies material advantages.

These blades significantly enhance mixing efficiency, refractory quality, and production stability. As vacuum brazing technology evolves, it will play an increasingly vital role in modern refractory manufacturing, driving efficiency, reducing downtime, and meeting stringent quality standards.

3. “Technology-driven refractory production: cutting-edge applications of carbide and steel mixer blades”

With industrial progress and escalating market demands, refractory production increasingly relies on advanced mixer blade technology. The integration of vacuum-brazed cemented carbide and steel blades represents a pivotal leap, driving efficiency, durability, and innovation in the industry.

Zhuzhou Old Craftsman leads with cutting-edge carbide-steel mixer blades, combining cemented carbide’s exceptional hardness and high-temperature stability with steel’s toughness and mechanical strength. Through vacuum brazing, these materials are perfectly bonded, creating blades that thrive in harsh, abrasive, high-heat environments—delivering superior wear resistance, uniform mixing, and significantly extended service life.

Key Optimization Factors:

*Carbide Grade Selection Refractory raw materials (hexamine, graphite, resin, alumina, magnesite) reach 9 Mohs hardness. Selecting the optimal carbide grade prevents rapid wear and ensures long-term performance.

*Vacuum Brazing Advantage Unlike high-frequency brazing—which causes cracking, oxidation, and carbide detachment—vacuum brazing eliminates internal stress and oxidation, ensuring zero fallout, consistent quality, and enhanced durability, despite higher technical complexity.

*Innovative Blade Design Precision shape refinements, based on real-world testing and customer feedback, have doubled blade lifespan, proving that intelligent design amplifies material performance.

Proven Impact:

-

Higher mixing efficiency and consistent material homogeneity

-

Reduced downtime and lower maintenance costs

-

Elevated refractory quality and production stability

Real-world applications confirm transformative results: faster production cycles, guaranteed product consistency, and strengthened enterprise competitiveness. These success stories provide a blueprint for the industry.

In summary, vacuum-brazed carbide-steel mixer blade technology is reshaping refractory manufacturing. As it evolves, it will continue to propel the industry toward greater intelligence, efficiency, and sustainability—setting new benchmarks for performance and reliability.

Manufacturing companies specializing in refractory bricks and other high melting point materials are increasingly adopting 3D printing technology in their production lines to replace the traditional manufacturing process of carbide intensive mixers blades. This advanced additive manufacturing method enables mass production of complex, customized blades with a wide range of geometries while significantly reducing production costs and cost per unit over the long term.

By precisely depositing material only where needed, 3D printing helps identify and eliminate unnecessary steps in manufacturing operations, drastically reduce waste, and minimize excess raw material consumption. The improved efficiency of the process not only shortens lead times for finished products but also lowers energy usage and thermal expansion-related defects during producing goods. As a result, companies achieve sustainable, cost-effective manufacturing with higher consistency and performance of the final carbide-intensive mixer blades.