1. “Refractory production status and challenges: the key role of mixer blade technology”

Refractory materials have always been one of the most important materials in the industrial field. They have excellent performance in harsh environments such as high temperatures, high pressure, acid and alkali, and are widely used in metallurgy, glass, cement, ceramics and other industries. However, with the continuous development of technology and the increasing market demand, traditional refractory production technology can no longer meet today’s complex and changing production needs and quality standards. In this context, the development of mixer blade technology has become particularly important.

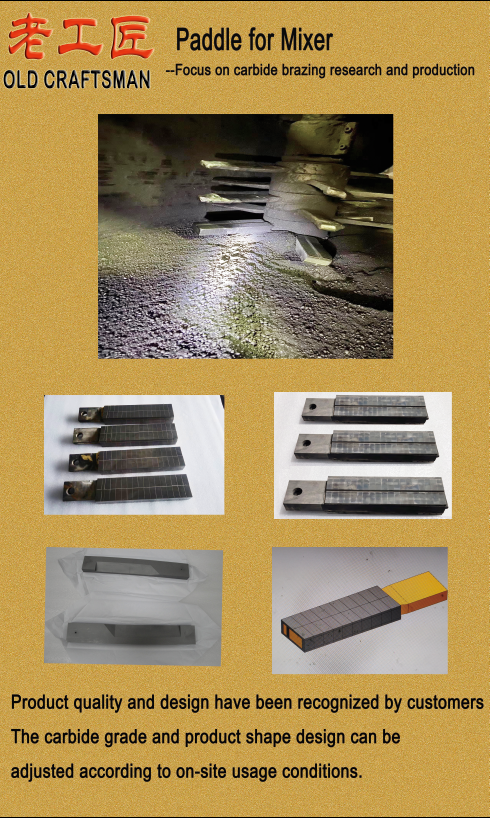

As a key component in the production process of refractory materials, the performance of mixer blades directly affects the quality and performance of refractory materials. However, traditional blade design faces a series of challenges when faced with complex raw material combinations and high-temperature environments, such as uneven mixing and poor wear resistance, which limits the production efficiency and quality of refractory materials.

In response to these challenges, the introduction of vacuum brazing technology of carbide and steel provides a new Carbide has excellent wear resistance and high temperature stability, while steel has good toughness and mechanical strength. The two are cleverly combined to overcome the shortcomings of traditional blades and take advantage of the respective materials. , greatly improving the durability and mixing effect of the mixer blades.

2. Analysis of vacuum brazing technology of cemented carbide and steel: why it has become the new favorite in the refractory materials industry

With the continuous advancement of industrial technology and the growing market demand, the refractory material industry is also constantly seeking innovation and breakthroughs. The application of vacuum brazing technology of cemented carbide and steel has become a new favorite in the refractory materials industry. The principles and advantages behind it are worthy of our in-depth understanding and discussion.

Carbide, as a material with excellent hardness and wear resistance, can be combined with steel to achieve complementary advantages. Through vacuum brazing technology, carbide and steel are tightly combined to form a wear-resistant and high-temperature-resistant mixer blade. This kind of blade not only has the wear resistance and high temperature stability of cemented carbide, but also has the good toughness and mechanical strength of steel, so it can operate stably for a long time in harsh production environments, greatly improving the production efficiency of refractory materials. and quality. The mixing knife blades produced by Zhuzhou Old Craftsmen adopt the Greatly improved. In order to improve the

*.The carbide grade. The main materials for the refractory brick are Hexamine, graphite, powder resin, and Alumina Oxide or Sinter Magnesite. Its hardness is 9 Mohs. So choosing a proper carbide is a key point, otherwise the blade will wear and tear easily.

**. The brazing method. As we all know high-frequency brazing is more economical and easier to handle, but its negative is also obvious: carbide cracks easily; carbide quality is compromised; carbide falls off easily, and so on. Vacuum brazing can solve the above negatives, but the technique is much harder than high-frequency brazing, and the cost is higher.

***. The design. We provided samples to our customers, and although the performance was good, the customer would like to have better performance. We only made a small design on the shape, and the use life was prolonged twice.

In general, the application of vacuum brazing technology of carbide and steel has brought new technological breakthroughs and production advantages to the refractory industry. As this technology continues to develop and improve, we can foresee that this new mixer blade technology will play an increasingly important role in future refractory production.

Innovative design of mixer blades: improving refractory material production efficiency and quality

As a vital component in the production process of refractory materials, the mixer blades’ design and performance directly affect the mixing effect and quality stability of the refractory materials. With the continuous development of technology and changing market demands, traditional blade design can no longer meet today’s complex and changing production needs and quality standards. Therefore, the innovative design of mixer blades has become the key to improving the efficiency and quality of refractory material production.

3. “Technology-driven refractory production: cutting-edge applications of carbide and steel mixer blades”

Technology-driven refractory production has always been one of the important topics in the industrial field. With the continuous development of the refractory industry and the increasing market demand, the requirements for mixer blade technology are also constantly increasing. In this context, the application of cemented carbide and steel mixer blade technology has become a highlight of refractory material production, leading the industry’s technological progress and innovation.

First, the latest carbide and steel mixer blade technology plays an important role in refractory production. By vacuum brazing cemented carbide and steel materials to form blades with wear resistance and high temperature resistance, the mixing efficiency and durability of the mixer can be effectively improved. This kind of blade not only has the wear resistance and high temperature stability of cemented carbide, but also has the good toughness and mechanical strength of steel. It can operate stably in harsh production environments and provides reliable technical support for the production of refractory materials.

Secondly, the application of cemented carbide and steel mixer blade technology not only improves production efficiency, but also promotes technological innovation in the refractory industry. By optimizing the design and At the same time, this new blade technology also provides more possibilities for the research and development and application of refractory materials, injecting new impetus into the sustainable development of the industry. In addition, cutting-edge application cases of cemented carbide and steel mixer blade technology are also worthy of attention. In modern industrial production, the demand for refractory materials is growing day by day, and the requirements for mixing technology are also getting higher and higher. By introducing the latest mixer blade technology, some refractory material For example, production efficiency has been greatly improved, product quality has been effectively guaranteed, and corporate competitiveness has been further enhanced. These successful application cases provide valuable experience and reference for other

In summary, the cutting-edge application of cemented carbide and steel mixer blade technology has brought new technological breakthroughs and production advantages to the production of refractory materials. As this technology continues to develop and improve, we can expect that carbide and steel mixer blade technology will continue to play an important role in promoting the refractory industry to move in a more intelligent and efficient direction.