High Pressure Grinding Rolls (HPGR) with tungsten carbide flanges are becoming increasingly important in modern mining operations due to their ability to improve grinding efficiency and reduce energy consumption. Here’s how these components maximize grinding performance:

Key Points on HPGR and Tungsten Carbide Flanges

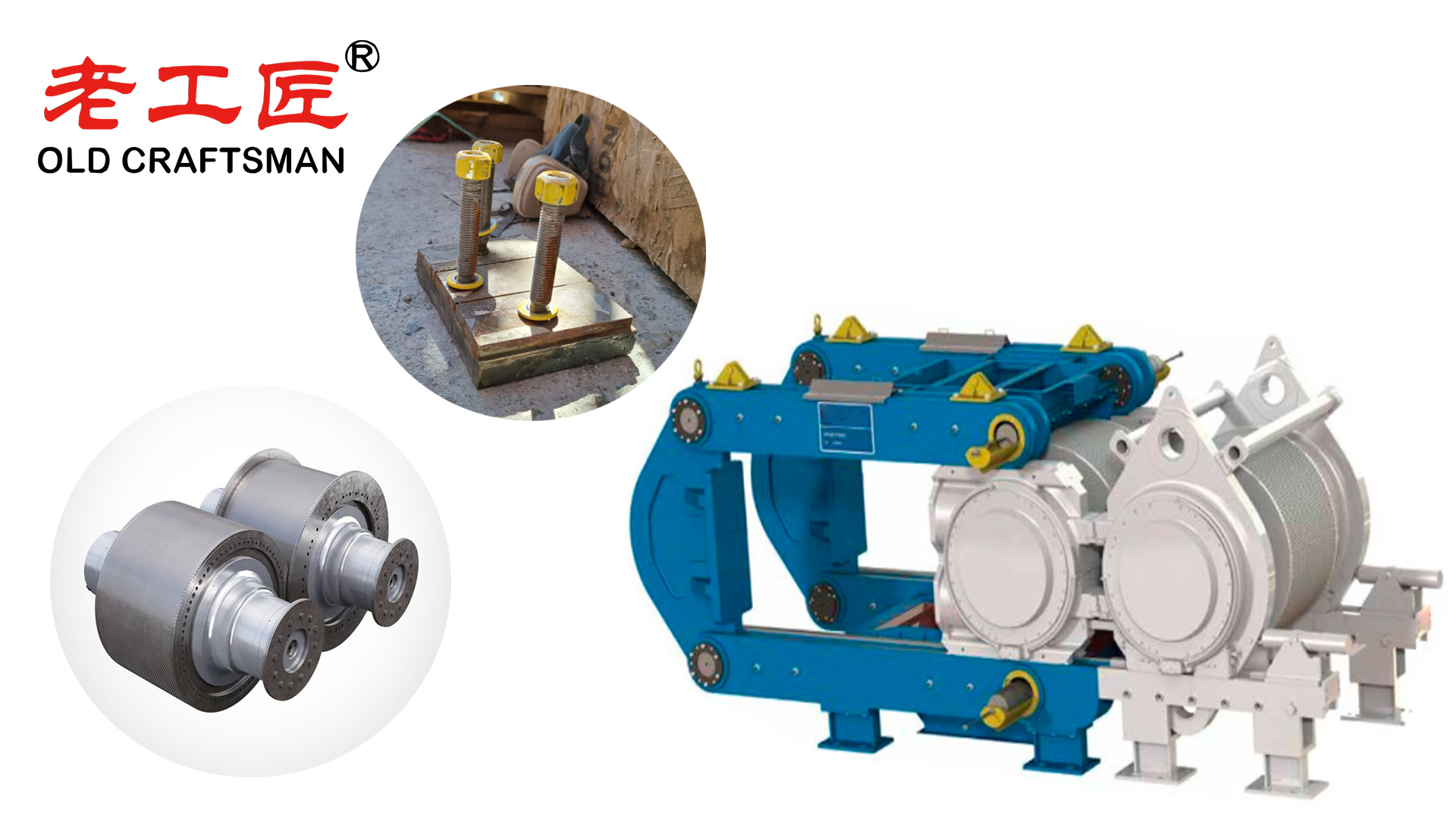

- HPGR Technology:

- HPGRs use two counter-rotating rolls to crush and grind ore, offering energy-efficient comminution compared to traditional methods like ball mills. They excel in processing hard and abrasive ores, reducing energy consumption by up to 50% in some cases.

- Benefits include uniform particle size distribution, enhanced mineral liberation through microcracking, and improved downstream processes like flotation or heap leaching.

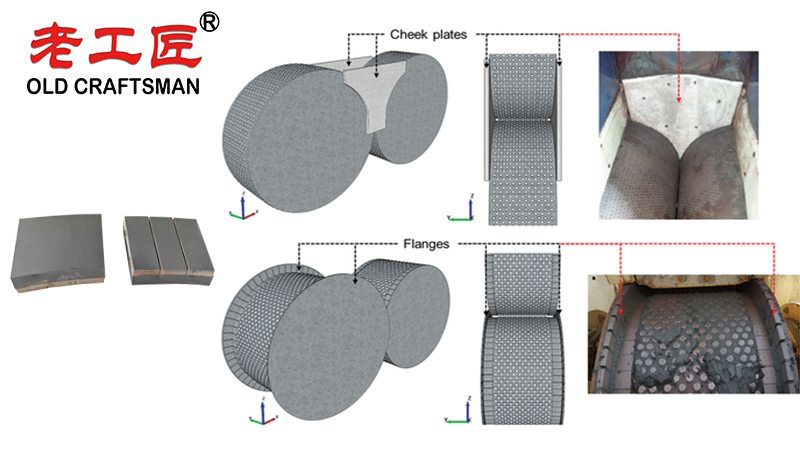

- Role of Tungsten Carbide Flanges:

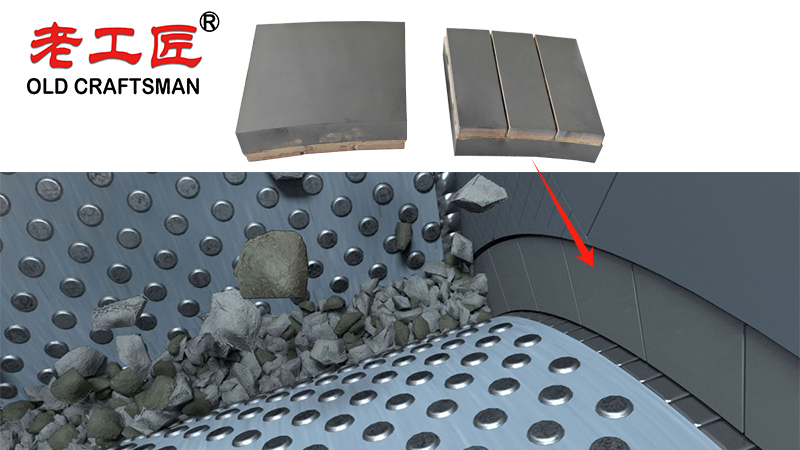

- Tungsten carbide (WC) is used in HPGR flanges and studs due to its exceptional hardness, wear resistance, and toughness, ideal for withstanding the extreme pressure and friction of grinding.

- Flanges, often studded with tungsten carbide, protect the roll edges, reducing wear and extending roll life (8,000–20,000 hours in hard rock applications). This minimizes maintenance cycles and downtime.

- Customizable tungsten carbide grades and stud sizes (with tolerances up to ±0.001mm) ensure precise installation, uniform stress distribution, and longer service life.

- Maximizing Grinding Efficiency:

- Energy Efficiency: HPGRs with tungsten carbide flanges reduce specific energy consumption by directing material straight to the crushing zone and optimizing pressure and speed.

- Throughput Optimization: Flange designs, like zz old craftsman’s flange, maximize material intake and prevent skewing, increasing throughput while maintaining product fineness.

- Wear Management: Advanced features like laser stud detection and rotating side plates (e.g., zz old craftsman’s HPGR flange) monitor wear and maintain uniform pressure, enhancing roll longevity and reducing costs.

- Operational Flexibility: Adjustable speed and pressure allow HPGRs to adapt to varying ore conditions, ensuring consistent performance.

- Maintenance and Cost Savings:

- Tungsten carbide’s durability reduces the frequency of roll replacements and maintenance, lowering operational costs.

- Regular maintenance, including inspections and lubrication, is critical to sustain efficiency and prevent excessive wear.

- Future Developments:

- Innovations include sensors for real time wear monitoring, automation for process optimization, and exploration of alternative wear-resistant materials like ceramics or diamond coatings.

Practical Considerations

- Customization: Select tungsten carbide grades based on ore hardness and abrasiveness. Companies like ZZ OLD CRAFTSMAN offer tailored stud compositions for specific HPGR models.

- Supplier: Leading HPGR wear parts manufacturers like ZZ OLD CRAFTSMAN provide advanced flange designs and wear protection systems.

- Cost-Benefit: While initial investment in tungsten carbide components is high, long-term savings from reduced energy use, maintenance, and downtime justify the cost.

For further details or quotes on tungsten carbide components, contact supplier like ZZ OLD CRAFTSMAN (sales@zzcraftsman.com) or visit manufacturer websites such as www.zzcraftsman.com for general inquiries.

High-Performance Grinding Rolls (HPGR) equipped with tungsten carbide (WC) flanges are the preferred solution in demanding mining and cement applications where extreme high temperature abrasion resistance and long wear life are critical. These corrosion resistant carbide flanges, manufactured from premium carbide grades and high quality carbide powders, feature densely packed carbide particles that deliver exceptional physical and mechanical properties, including outstanding hardness, compressive strength, and dimensional stability under severe service conditions.

By selecting the optimal carbide grade for each specific material selection process, HPGR flanges significantly increase wear resistance compared to conventional hard-facing materials, dramatically extending maintenance intervals and reducing downtime in high-pressure grinding operations. The same advanced tungsten carbide technology proven in HPGR flanges is also widely used in cutting tools, ball mill liner protection, and other engineering applications exposed to intense abrasive wear, delivering superior performance and cost effective wear life in the most challenging environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding