Tungsten carbide (WC) chute liners and wear protection solutions are widely used in industries where abrasion, erosion, and impact resistance are critical. Tungsten carbide is one of the hardest materials available, second only to diamond, making it ideal for protecting equipment in harsh environments.

Key Features of Tungsten Carbide Chute Liners & Wear Protection:

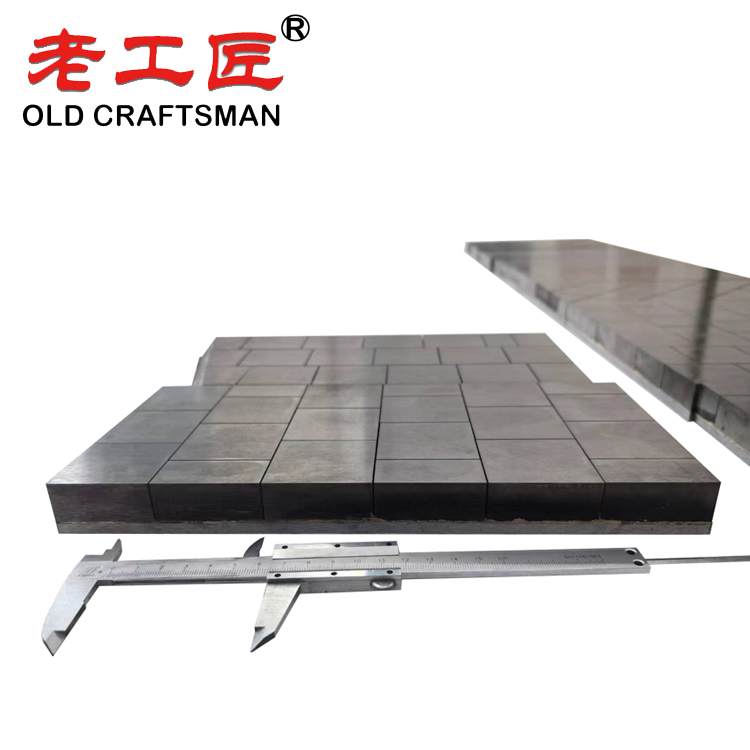

- Extreme Hardness (HV 1500-2000) – Resists abrasion from high velocity materials like coal, ore, gravel, and slag.

- High Impact Resistance – Unlike ceramic liners, tungsten carbide can withstand moderate impacts without cracking.

- Corrosion Resistance – Performs well in wet or chemically aggressive environments.

- Long Service Life – Outlasts steel, rubber, and ceramic liners by 5-10 times, reducing downtime and replacement costs.

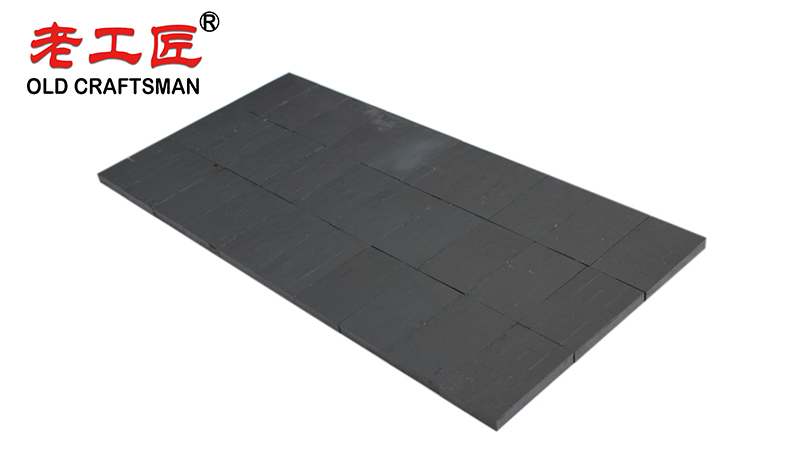

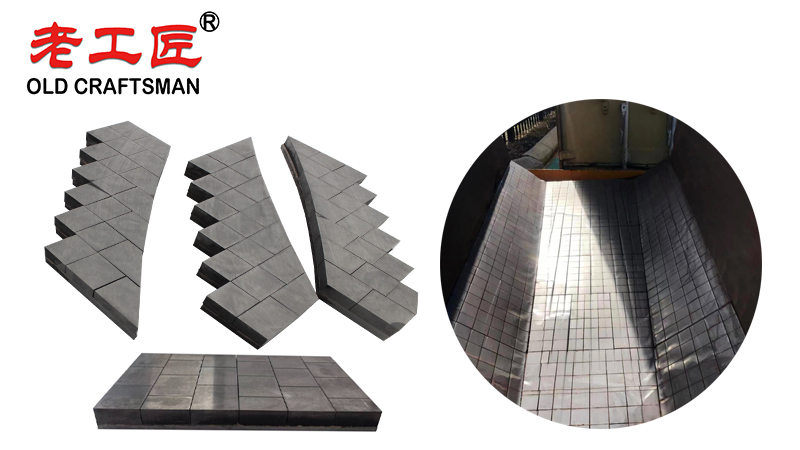

- Customizable Shapes – Available in tiles, plates, rods, or embedded in steel backing for easy installation.

Common Applications:

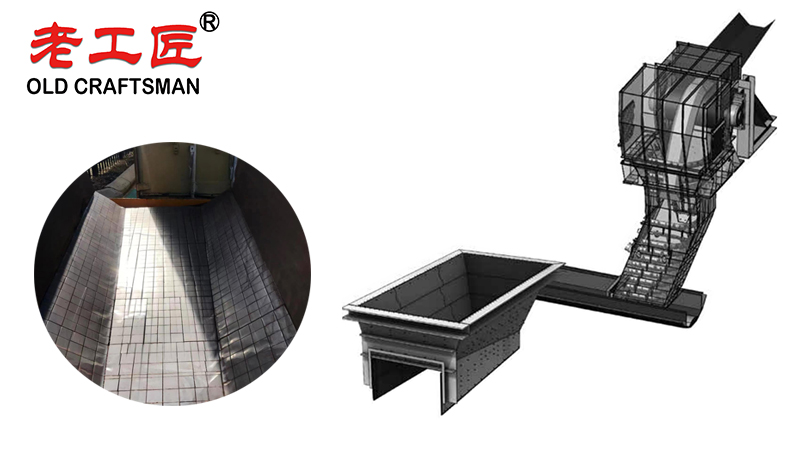

- Mining & Quarrying – Chutes, hoppers, crusher liners, and conveyor transfer points.

- Cement & Power Plants – Ash handling, clinker chutes, and raw material transfer.

- Steel & Foundries – Slag handling, blast furnace liners, and shot blasting equipment.

- Aggregate & Sand Processing – High wear zones in screening and crushing systems.

Types of Tungsten Carbide Wear Solutions:

- Tungsten Carbide Tiles/Plates – Bolted or welded onto chutes and hoppers.

- Carbide-Rubber Composite Liners – Combines impact absorption with wear resistance.

- Carbide-Embedded Steel Plates – Tungsten carbide inserts in a steel matrix for heavy duty applications.

- Cemented Carbide Overlays – Hardfacing with WC for repair and reinforcement.

Advantages Over Other Materials:

| Material | Wear Resistance | Impact Resistance | Cost Efficiency |

|---|---|---|---|

| Tungsten Carbide | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | High initial cost, but long-term savings |

| Ceramic Liners | ⭐⭐⭐⭐ | ⭐⭐ | Brittle, prone to cracking |

| AR Steel (400-500 Brinell) | ⭐⭐ | ⭐⭐⭐ | Cheaper but wears quickly |

| UHMW Plastic | ⭐⭐ | ⭐⭐⭐ | Lightweight but soft |

Installation & Maintenance Tips:

- Ensure proper surface preparation (clean, weld ready steel).

- Use appropriate fastening (welding, bolting, or adhesive bonding).

- Inspect regularly for wear or loosening, especially in high impact zones.

A mining carbide chute liner is a high performance, heavy duty wear solution specifically designed for harsh environments in the mining and bulk material handling industries. Made from advanced abrasion resistant alloy steels infused with tungsten carbide overlays, it delivers exceptional abrasion resistance, high temperature stability, and superior tensile strength compared to conventional abrasion-resistant steels (such as AR400 or AR500).

Through a precise manufacturing process that combines vacuum brazing or overlay welding, the carbide particles are uniformly embedded into the steel substrate, creating outstanding mechanical properties and dramatically extending service life even under extreme impact, sliding abrasion, and high temperature conditions.

In real-world industrial applications, these liners significantly reduce wear and tear on critical pieces of equipment such as transfer chutes, hoppers, and truck bodies. Independent testing methods (including ASTM G65 dry sand abrasion tests and field trials) consistently demonstrate 8–15 times longer wear life than standard materials, helping operators prevent unplanned maintenance, minimize downtime, and control long term costs effectively.

For demanding specific applications where traditional liners fail quickly, mining carbide chute liners provide a proven, reliable, and cost effective solution that keeps operations running longer and more profitably.

Conclusion:

Tungsten carbide chute liners provide unmatched wear protection in extreme conditions, significantly extending equipment lifespan. While the upfront cost is higher than alternatives, the reduction in maintenance and downtime makes it a cost effective choice for heavy industries.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding