Here is a detailed and professional overview of optimizing HPGR (High Pressure Grinding Roll) mining processing with custom tungsten carbide edge blocks.

Executive Summary

The optimization of High Pressure Grushing Rolls (HPGR) is critical for achieving energy efficient comminution in modern mining operations. A primary area for performance enhancement lies in the durability and design of the studs and edge blocks that protect the roll tires. Custom tungsten carbide edge blocks represent a significant technological advancement over standard designs, offering dramatically extended service life, reduced downtime, improved throughput, and enhanced process stability. By tailoring the geometry, carbide grade, and base material to specific ore characteristics and operational parameters, mines can unlock substantial operational and financial benefits.

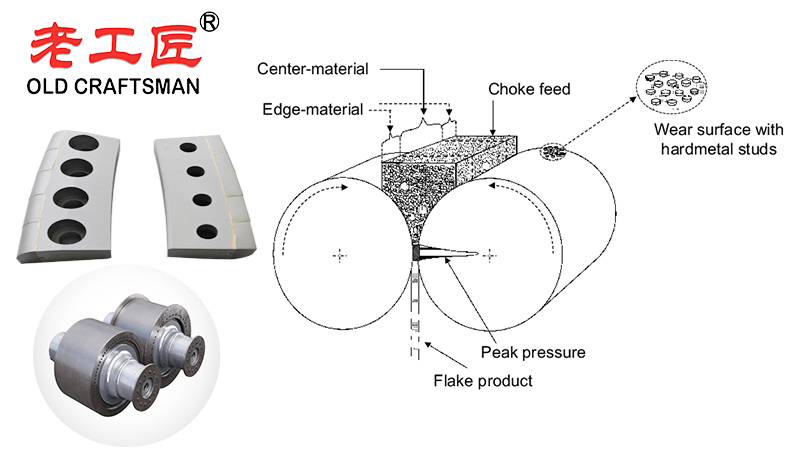

1. The Role of Edge Blocks in an HPGR

HPGRs operate by compressing a feed material between two counter rotating rolls. The immense pressure (up to 300+ MPa) causes inter-particle crushing. The roll surface is protected by studs (in the central grinding area) and edge blocks (along the sides).

The key functions of edge blocks are:

- Containment: To form a physical wall that prevents feed material from spilling over the sides of the rolls without being crushed, which is critical for maintaining a pressurized particle bed.

- Wear Protection: To shield the softer roll tire material (typically steel) from the highly abrasive ore, which would otherwise rapidly wear down the edges, compromising containment and efficiency.

- Generating Autogenous Layer: Like the studs, edge blocks help generate a compacted, wear resistant “autogenous layer” or “cake” on the roll surface, which is the primary mechanism for protecting the tire and achieving efficient grinding.

2. The Problem with Standard/Off-the-Shelf Edge Blocks

Standard edge blocks are often a compromise. They may not be optimized for:

- Specific Ore Abrasiveness: A block designed for moderately abrasive gold ore will fail rapidly in a highly abrasive iron ore application.

- Feed Size Distribution: Large, sharp feed particles require a different impact and wear resistance compared to fine, gritty feed.

- Operating Pressure: Higher operating pressures demand superior mechanical strength and fracture resistance from the carbide and its connection to the base.

- Roll Diameter & Speed: These factors influence wear patterns and impact forces.

Using ill-fitting edge blocks leads to:

- Rapid Wear: Short service life, requiring frequent and costly shutdowns for replacement.

- Uneven Wear: Poor containment leads to edge spillage, which in turn causes uneven wear across the roll width, reducing efficiency and product quality.

- Catastrophic Failure: If a block breaks or falls out, it can cause severe damage to the opposing roll and the tire itself, leading to extremely expensive repairs and extended downtime.

- Reduced Throughput: As edge blocks wear, containment fails, the operating gap changes, and the machine cannot maintain optimal pressure, forcing a reduction in feed rate.

3. How Custom Tungsten Carbide Edge Blocks Optimize Performance

Customization addresses the shortcomings of standard blocks by engineering a solution for the exact application.

a) Material Science Optimization: Choosing the Right Carbide Grade

Tungsten carbide (WC) is not a single material. Its properties are determined by the grain size of the tungsten carbide particles and the percentage and type of cobalt (Co) binder.

- Fine-Grained Carbide: Higher wear resistance but lower impact strength. Ideal for highly abrasive but less impact-prone ores (e.g., some iron ores, copper porphyry).

- Coarse-Grained Carbide: Higher impact and fracture toughness but slightly lower wear resistance. Ideal for ores with large, hard feed particles that cause high impact stresses.

- Medium-Grained Carbide: A balanced option for many applications.

- Custom Binder Alloys: Advanced binders (e.g., nickel-chromium) can be used for ores with specific corrosion issues alongside abrasion.

A custom provider will analyze the ore’s Abrasion Index (e.g., AI from JK Drop Weight Test) and work index to recommend the optimal carbide grade.

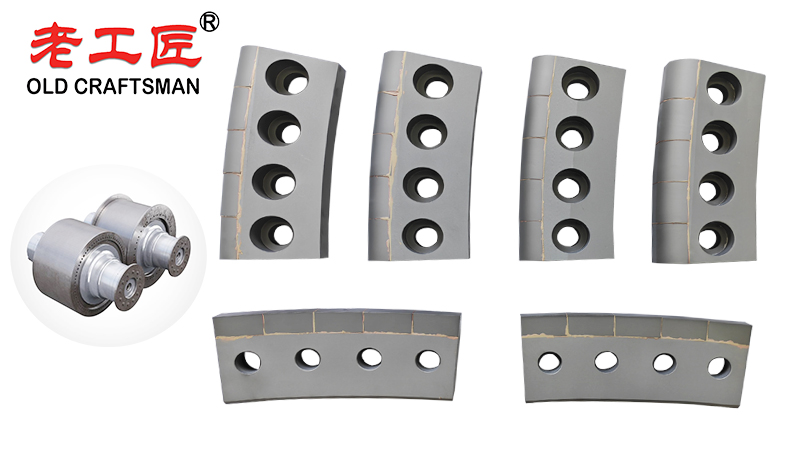

b) Geometrical Design Optimization

The shape of the edge block is critical for performance and longevity.

- Profile: The profile can be customized to improve the “grip” on the ore and promote the formation of a stable autogenous layer.

- Height and Width: Custom dimensions ensure a perfect fit and optimal containment for the specific roll tire design.

- Bevels and Angles: Strategic angling can deflect material inward, reducing side wear and improving energy efficiency.

- Interlocking Designs: Some custom blocks are designed to interlock with each other, creating a continuous, robust wall that is more resistant to material penetration and block displacement.

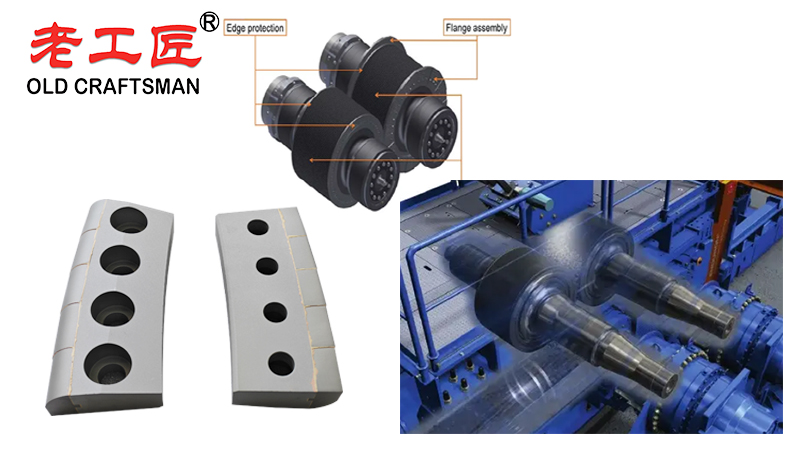

c) Mechanical Integration: The Base and Attachment

The block is typically a carbide tip brazed onto a steel base.

- Base Material: The steel base can be made from specially forged, high strength, and tough alloys to withstand the bending and shear forces without deforming.

- Brazing Process: A critical step. Custom manufacturers use controlled atmosphere furnaces and high quality braze alloys to create a void-free, incredibly strong bond between the carbide and the steel. This is paramount to preventing tip loss.

- Attachment System: The design of the “dove-tail” or other mechanical lock that secures the block into the tire can be optimized for easier installation and removal, reducing maintenance time.

4. Tangible Benefits of Optimization

- Extended Service Life: The primary benefit. Custom blocks can last 2 to 4 times longer than standard blocks, directly extending maintenance intervals.

- Reduced Downtime: Longer life means fewer shutdowns for block replacement. Faster installation due to better design further reduces downtime.

- Increased Availability and Throughput: The HPGR can operate at designed capacity for longer periods, improving overall circuit throughput.

- Improved Product Consistency: Maintained containment ensures stable operating conditions (pressure, gap, power draw), leading to a more consistent product size distribution, which benefits downstream processes.

- Lower Total Cost of Ownership (TCO): While the upfront cost per custom block is higher, the dramatically extended life, reduced labor for changes, and avoidance of catastrophic failure lead to a significantly lower cost per operating hour and per ton of ore processed.

- Enhanced Safety: More predictable wear patterns and reduced frequency of hazardous maintenance tasks inside the crusher contribute to a safer work environment.

5. Implementation Process for a Mining Operation

- Application Analysis: Collaborate with a specialist manufacturer. Provide ore characteristics (Abrasiveness, Work Index, SiO2 content, feed size distribution) and HPGR operational data (pressure, speed, power, current wear rates).

- Design and Quotation: The manufacturer will propose a custom design, carbide grade, and provide a cost-benefit analysis showing projected ROI.

- Field Trials: Start with a trial set on one roll. Monitor performance meticulously measure wear rates, document downtime, and analyze product quality.

- Full Deployment: Upon successful trial, equip all HPGRs with the custom solution.

- Continuous Monitoring and Feedback: Work with the supplier to review performance data. This feedback loop can lead to further refinements in future orders.

High-performance HPGR edge blocks for mining crushers are manufactured using premium cemented tungsten carbide (WC) containing small amounts of specially selected high quality tungsten carbide powder with optimized particle size and extremely high melting points. In the United States and worldwide, these wear resistant tungsten carbide wear parts are produced under ultra high pressure and high temperature sintering conditions to achieve exceptional high density and outstanding toughness. The precisely cut edges of the HPGR studs provide superior protection against abrasive materials, dramatically extending service life compared to conventional solutions. Interestingly, the same advanced grades of tungsten carbide used in these heavy duty industrial applications are also popular in high end jewelry, such as durable and scratch-resistant tungsten carbide wedding rings valued for their lifelong brilliance and precious metal like appearance.

Conclusion

In the pursuit of operational excellence and cost reduction, optimizing the wear components of key equipment like HPGRs is a high-value strategy. Custom tungsten carbide edge blocks are not just replacement parts; they are engineered solutions. By moving from a standardized, one-size-fits-all approach to a customized, application specific strategy, mining operations can achieve a dramatic improvement in reliability, efficiency, and profitability of their comminution circuit. The investment in customization pays for itself many times over through reduced downtime, lower maintenance costs, and increased production.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding