The High Pressure Grinding Roll (HPGR) has revolutionized mineral comminution, offering significant energy savings and superior particle liberation compared to traditional SAG or ball mills. However, a critical operational challenge has been the rapid wear of its cheek plates, which guide and contain the feed material. The adoption of tungsten carbide reinforced cheek plates represents a transformative high wearing solution, directly optimizing the entire mineral processing circuit.

Here’s a breakdown of how this specific solution drives optimization:

1. The Core Problem: Traditional Cheek Plate Wear

Standard cheek plates are typically made from durable but soft steel alloys. In the harsh environment of an HPGR, they are subjected to:

- Abrasive Wear: Constant sliding contact with hard, abrasive ore.

- Impact Fatigue: Repeated stress from feed material and pressure fluctuations.

- Resulting Issues:

- Frequent Stoppages: Production must be halted every 100-500 hours for replacement or hardfacing.

- Loss of Efficiency: As wear progresses, the gap between the roll and the cheek plate increases, causing side leakage. This uncrushed material bypasses the compression zone, reducing throughput and overall circuit efficiency.

- Increased Operating Costs: High labor costs for changes, wear and tear downtime losses, and consumable costs add up significantly.

- Inconsistent Product Quality: Fluctuating cheek plate geometry leads to variability in the particle size distribution (PSD) of the product, negatively affecting downstream processes like flotation or leaching.

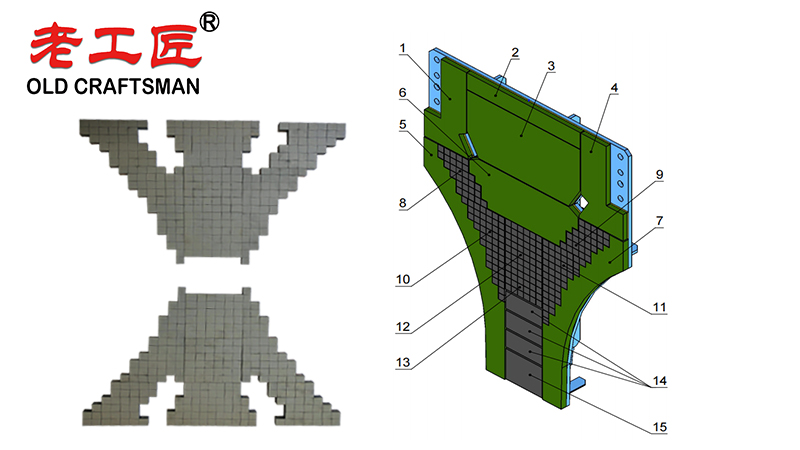

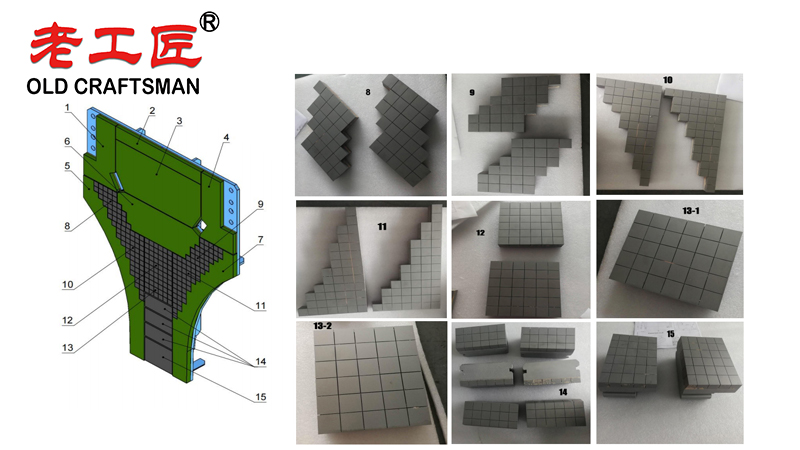

2. The Solution: Tungsten Carbide Cheek Plates

This solution involves replacing the traditional steel wear plates with plates that are either:

- Carbide-Reinforced Steel Plates: A steel base with strategically embedded, robust blocks of tungsten carbide.

- Full-Carbide Tiles: In extreme applications, entire tiles made from specialized carbide composites.

Why Tungsten Carbide?

Tungsten carbide is a ceramic metallic composite (cermet) known for extreme:

- Hardness: Typically 1300-2000 HV (Vickers Hardness), making it vastly more resistant to abrasion than the hardest steels (~800 HV) impact resistance.

- Wear Resistance: It can withstand high abrasiveness forces orders of magnitude longer than steel during material flow, it is wear resistant materials, high wear resistance.

- Compressive Strength: It maintains its integrity under the enormous pressures (up to 5.5 N/mm²) generated in the HPGR nip.

3. How the Carbide Solution Optimizes Mineral Processing

| Optimization Parameter | Traditional Steel Plates | HPGR with Carbide Cheek Plates | Impact on Mineral Processing |

|---|---|---|---|

| Uptime & Availability | Low (Frequent changes) | Very High | ↑ Throughput: Major reduction in unplanned stoppages. Plant availability can increase by 5-10%, translating to thousands of additional tons processed annually. |

| Operating Cost (OPEX) | High (Labor, parts, downtime) | Drastically Reduced | ↑ Profitability: While the capex is higher, the ROI is rapid due to eliminated hardfacing costs, reduced labor, and maximized production. |

| Energy Efficiency (kWh/t) | Degrades with wear | Consistently Optimal | ↑ Sustainability: The HPGR operates at peak efficiency 100% of the time. No energy is wasted compressing ore that side leaks. This protects the HPGR’s key advantage of low specific energy consumption. |

| Throughput (t/h) | Declines over time | Consistently High | ↑ Production Rate: Maintains designed feed rate and pressure without degradation from increasing side leakage. |

| Product Quality (PSD) | Inconsistent, coarser over time | Consistent and Finer | ↑ Downstream Recovery: A stable, finer PSD improves the efficiency of subsequent processes (e.g., higher liberation for flotation, faster leach kinetics). This can boost metal recovery by 1-3%, a massive financial gain. |

| Maintenance | Labor-intensive, hazardous | Minimal & Predictable | ↑ Safety & Planning: Changes are infrequent (every 6-12+ months instead of weeks). Maintenance can be planned during scheduled shutdowns, improving safety and resource planning. |

4. Key Considerations for Implementation

- Capital Expenditure (CAPEX): The initial investment for carbide cheek plates service life is 5-10x higher than for steel plates. However, the Total Cost of Ownership (TCO) is almost always lower.

- Application-Specific Design: Not all carbide is the same. The grade, size, and pattern of the carbide inserts must be engineered for the specific ore’s abrasiveness (e.g., iron ore vs. copper porphyry vs. diamond ore).

- Proper Installation: Requires precise installation to ensure a perfect fit and avoid creating new points of wear.

- Monitoring: While wear liners are drastically reduced, monitoring protocols should still be in place to plan for eventual replacement during a planned maintenance shutdown, and reduce maintenance cost.

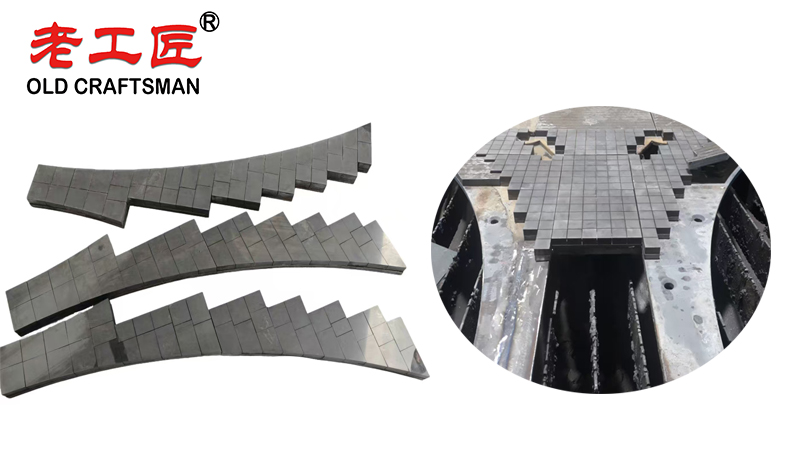

In modern mineral processing plants, high pressure grinding rolls (HPGR) equipped with high-quality tungsten carbide cheek plates and carbide wear parts have significantly extended equipment service life while dramatically improving crushing and grinding efficiency across a wide range of raw materials and particle sizes.

These wear-resistant HPGR components, typically manufactured from premium stainless steel studded with tungsten carbide wear inserts, protect the roller side walls from abrasive waste rock and high impact loads, reducing downtime and maintenance costs in large scale operations.

Downstream, the finely liberated ore feeds into conventional circuits incorporating screening equipment, gravity separation, magnetic separation, and froth flotation units, all optimized during the overall plant design to maximize metal recovery in extractive metallurgy processes.

The combination of advanced HPGR technology with strategically selected wear resistant materials has become one of the most common types of solutions for achieving higher throughput, lower energy consumption, and superior liberation in contemporary mineral processing facilities.

Conclusion: A Strategic Upgrade

Implementing a tungsten carbide cheek plate solution is not merely a component change; it is a strategic optimization of the comminution circuit. It directly addresses the primary weakness of the otherwise highly efficient HPGR technology.

By maximizing availability, ensuring consistent and optimal performance, and reducing operating costs, this solution unlocks the full potential of HPGRs. The result is a more reliable, profitable, and energy efficient mineral processing plant, with positive ripple effects on downstream recovery and overall operational stability. For any operation serious abrasive wear about optimizing their HPGR performance, carbide cheek plates are a critical investment, for long tem, our HPGR cheek plates in material handling, reducing maintenance, it plays a positive and effective role.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding