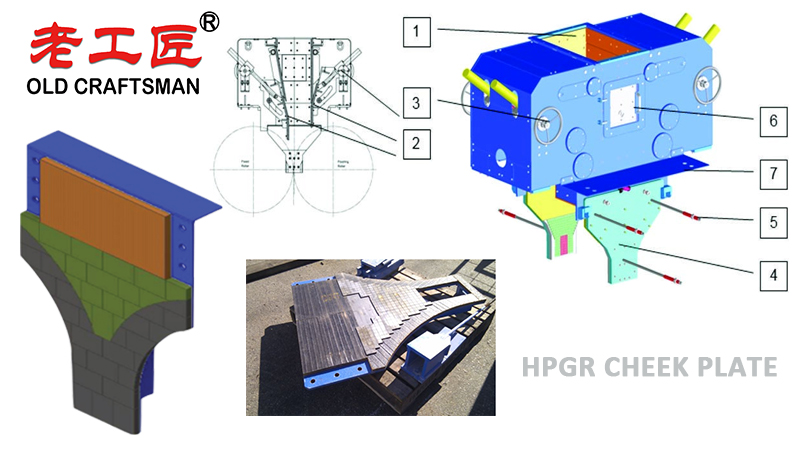

High Pressure Grinding Rolls (HPGR) have become a critical technology in modern mineral processing, offering energy efficient comminution with lower operating costs compared to traditional grinding methods. The cheek plates are essential components that contain the feed material between the rolls during the grinding process.

Benefits of Tungsten Carbide Cheek Plates

Superior Wear Resistance

- Tungsten carbide offers 4-7x longer service life compared to conventional manganese steel plates

- Maintains geometric integrity longer, ensuring consistent grinding performance

- Reduces frequency of maintenance shutdowns

Operational Advantages

- Higher pressure capability (up to 300 N/mm²)

- Improved energy efficiency (15-30% savings vs conventional materials)

- Better particle size distribution control

- Reduced contamination from wear debris

Customization Options

Material Composition

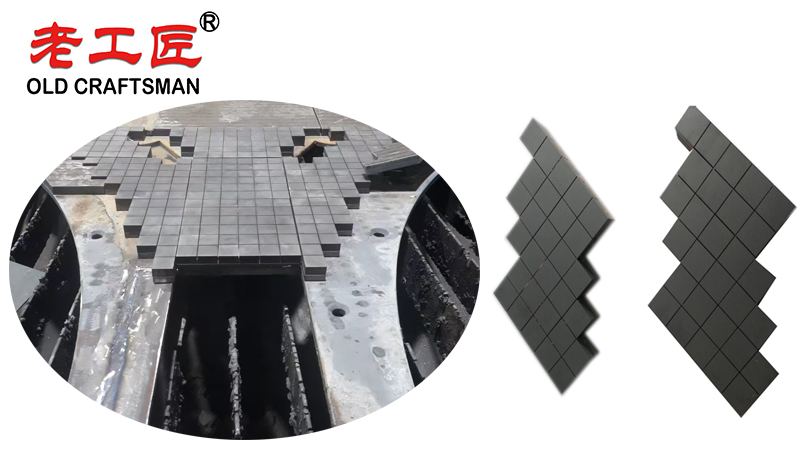

- Adjustable carbide grain size (sub-micron to 6+ microns)

- Variable binder content (6-30% cobalt/nickel)

- Gradient structures for optimized wear profiles

Geometric Design

- Custom profiles to match specific ore characteristics

- Integrated wear monitoring features

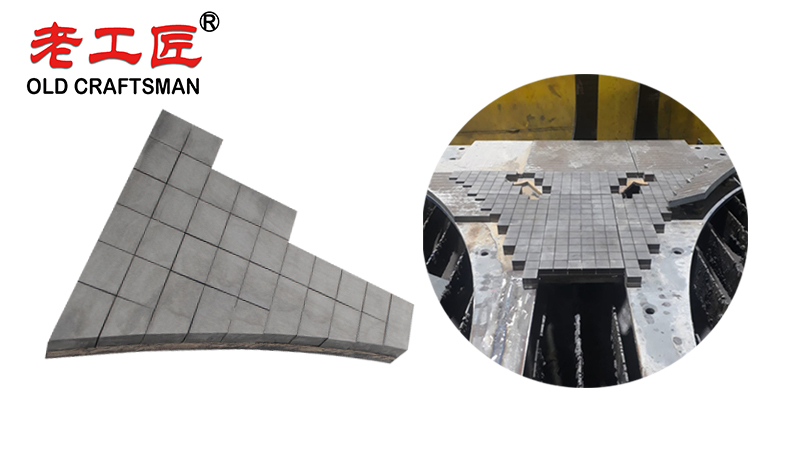

- Modular designs for partial replacement

- Surface texturing options for optimal material flow

Implementation Considerations

Installation Best Practices

- Proper pre-heating procedures to prevent thermal shock

- Precision alignment techniques

- Break-in protocols for optimal performance

Operational Optimization

- Pressure and feed rate adjustments for carbide plates

- Wear monitoring and predictive maintenance scheduling

- Integration with process control systems

Cost-Benefit Analysis

While initial costs are higher than conventional materials, tungsten carbide cheek plates typically demonstrate:

- 40-60% lower cost per operating hour

- 30-50% reduction in replacement labor costs

- Improved throughput and product quality benefits

Case Studies

[Examples from major mining operations showing 6-9 month service life extensions and 18-22% energy savings would be included here in a full report]

HPGR (High Pressure Grinding Rolls) have become a critical technology in mineral processing due to their energy efficient high-pressure grinding mechanism. One of the most important wear parts in HPGRs are the carbide cheek plates, which are positioned on the sides of the rolls to prevent material leakage and protect the roll tires from abrasive wear. These cheek plates are typically made of tungsten carbide studs embedded in a steel matrix, offering exceptional wear resistant materials with low coefficient of friction and outstanding ability to withstand extreme mechanical loads and high temperatures (often exceeding 100–150 °C during operation). The mechanical properties of these carbide composites high hardness, compressive strength, and toughness allow them to resist permanent deformation under the intense pressures of high pressure grinding rolls while maintaining dimensional stability and long service life. In industrial applications ranging from cement clinker to hard-rock mining, selecting the right types of material for cheek plates is crucial for cost effective operation, as premature failure leads to expensive downtime and replacement costs. Additionally, modern production processes for these wear plates increasingly focus on sustainable raw materials and lower environmental impact, helping the mining industry reduce its overall ecological footprint while delivering reliable, high performance wear parts that play an important role in ensuring continuous and efficient HPGR operation.

Conclusion

Custom tungsten carbide cheek plates represent a significant advancement in HPGR technology, offering mining operations substantial improvements in efficiency, productivity, and total cost of ownership. The ability to tailor material properties and geometries to specific ore characteristics makes this solution particularly valuable for operations processing abrasive ores.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding