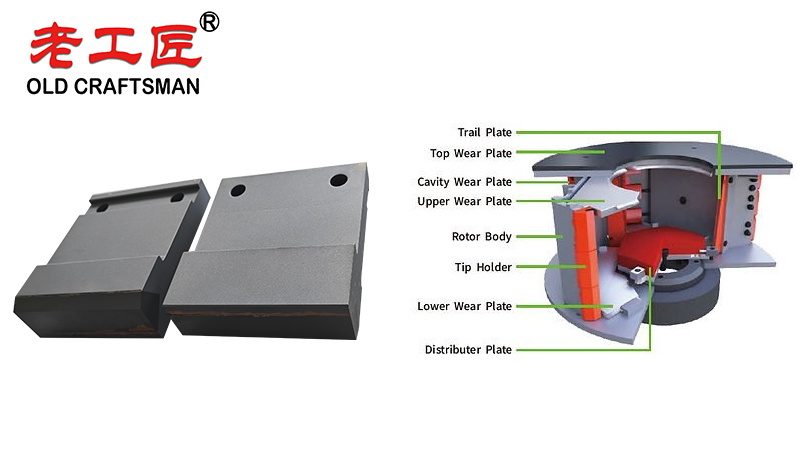

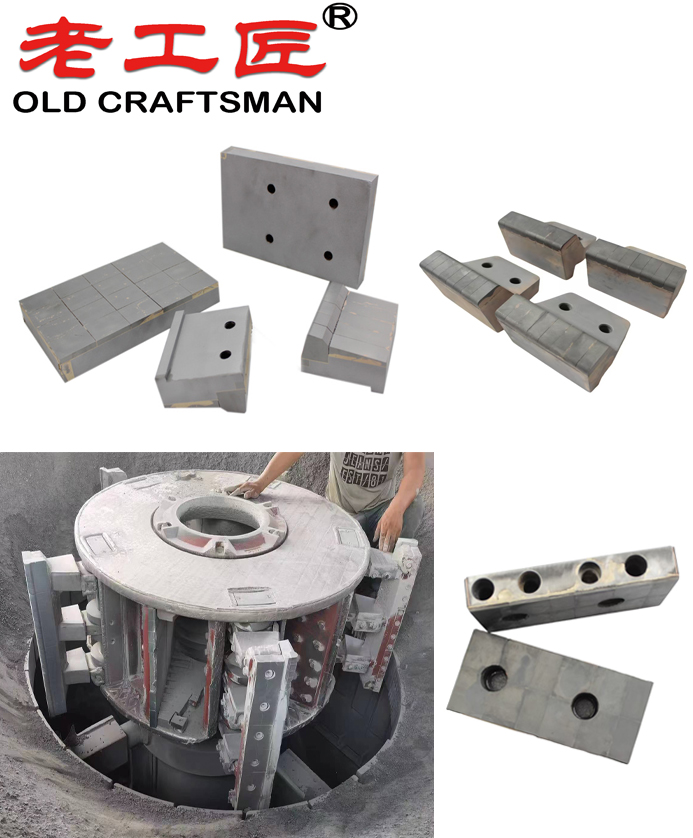

The Vertical Shaft Impactor (VSI) crusher is a cornerstone of modern aggregate production and manufactured sand (M-Sand) plants. Its unique rock-on-rock and rock-on-metal crushing action provides superior product shape, consistent gradation, and the ability to handle highly abrasive materials. However, the very nature of its operation accelerating rock at high velocities places immense stress and wear on its core components, particularly the rotor tips.

For decades, operations managers have battled the high costs and downtime associated with frequent rotor tip replacement. Today, the advent of advanced tungsten carbide rotor tips is proving to be a game-changer, directly addressing the most persistent challenges in VSI operation.

The Core Challenge: The Economics of Wear

The primary function of VSI rotor tips is to impart kinetic energy to the feed material. This constant, high velocity impact leads to rapid wear. The traditional challenges stemming from this wear are:

- High Operational Costs: Frequent replacement of tips and the associated labor and downtime are a significant expense.

- Unplanned Downtime: A single worn-out tip can lead to catastrophic damage to the rotor itself, forcing unscheduled and costly shutdowns.

- Inconsistent Product Quality: As tips wear, the crusher’s internal geometry changes. This leads to a gradual degradation of product shape (cubicity) and an unpredictable shift in gradation, moving the product out of specification.

- Reduced Throughput: A worn rotor is less efficient at accelerating material, which can lead to a drop in crusher capacity and overall plant throughput.

How Advanced Carbide Tips Provide the Solution

Advanced carbide tips are not merely “harder” steel. They are a composite material where extremely hard tungsten carbide particles are embedded within a tough, wear resistant steel matrix. This combination delivers specific performance benefits that directly counter the common challenges.

1. Drastically Extended Service Life

- The Problem: Standard martensitic steel tips can wear out in as little as 40-60 hours when processing highly abrasive materials like granite, quartzite, or slag.

- The Carbide Solution: Tungsten carbide is one of the hardest materials available for industrial applications, second only to diamond. Its abrasion resistance is an order of magnitude greater than that of the best steel.

- The Result: Operations routinely report 3x to 5x longer service life with carbide tips compared to premium steel tips. In some highly abrasive applications, the life increase can be even more dramatic, turning a weekly maintenance task into a monthly or quarterly one.

2. Unmatched Cost-Per-Ton Efficiency

- The Problem: While the initial purchase price of carbide tips is higher, focusing on this alone is a classic case of “penny wise, pound foolish.”

- The Carbide Solution: The true measure of value in crushing is cost-per-ton. By lasting significantly longer, carbide tips spread their higher initial cost over a much larger volume of processed material.

- The Result: A substantial reduction in the total cost-per-ton of finished product. The savings in labor, downtime, and the cost of replacement parts themselves make carbide tips the most economically rational choice for most abrasive applications.

3. Superior and Consistent Product Quality

- The Problem: Worn steel tips change the “throw” of the rotor, leading to poor impact angles. This produces more flaky and elongated particles, degrading the premium, cubical product that the VSI is designed to create.

- The Carbide Solution: Carbide tips maintain their original profile and weight for a much longer portion of their operational life. This ensures a consistent feed trajectory and optimal rock-on-rock impact.

- The Result: The crusher produces a consistent, in-spec product with superior cubicity from the start of a tip’s life until the very end. This is critical for producing high-value M-Sand for concrete or asphalt where particle shape is paramount.

4. Enhanced Operational Uptime and Predictability

- The Problem: Unpredictable tip failure leads to reactive maintenance, disrupting production schedules and causing bottlenecks.

- The Carbide Solution: The long and consistent wear life of carbide tips allows for proactive, planned maintenance. Operations can schedule tip changes during regular maintenance windows with a high degree of confidence.

- The Result: Maximized plant availability and throughput. Maintenance teams can plan their work, and production managers can meet their targets without the fear of unexpected crusher failures.

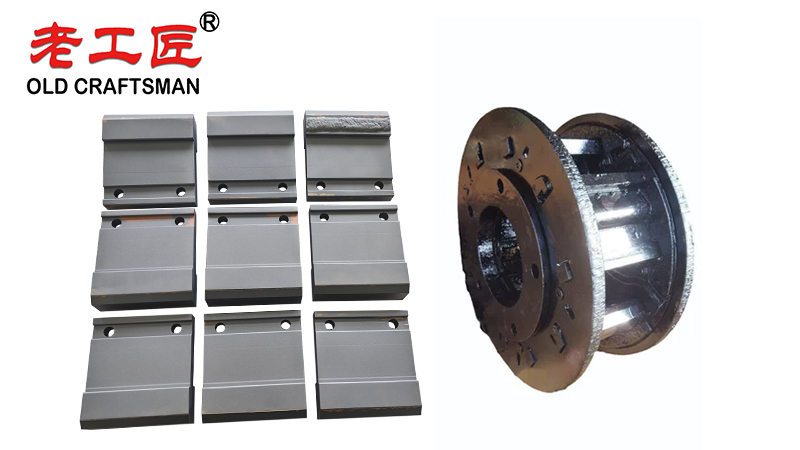

Key Features of Advanced Carbide Tips

Not all carbide tips are created equal. When selecting tips, look for these advanced features:

- High Carbide Volume & Quality: A higher volume of premium, fine grained tungsten carbide ensures maximum wear resistance without brittleness.

- Optimized Metallurgical Bonding: The process of fusing the carbide to the steel body is critical. Advanced techniques ensure the carbide does not delaminate or break off under extreme impact.

- Precision Engineering: Tips must be perfectly balanced and dimensionally accurate to ensure smooth operation and even wear across the entire rotor, preventing vibration and premature bearing failure.

- Application-Specific Designs: Leading manufacturers offer different carbide grades and tip geometries optimized for specific materials, from highly abrasive stone to less abrasive but tough recycled concrete.

Conclusion: A Smart Investment for Modern Operations

The shift from traditional steel to advanced carbide rotor tips is more than just a component upgrade; it’s a strategic operational decision. By directly addressing the core challenges of wear, cost, and product consistency, carbide tips transform the VSI crusher from a high maintenance necessity into a reliable, high performance asset.

Our company specializes in premium VSI carbide rotor tips made from high quality tungsten carbide wear parts that deliver exceptional performance in vertical shaft impact (VSI) crushers. Manufactured through advanced manufacturing processes and using the most wear resistant materials available, including highly abrasion resistant tungsten carbide alloys, these rotor tips offer superior high strength and reliability even under high temperatures and the toughest operating conditions. Designed for a wide range of specific applications and various types of feed material, they significantly reduce operating costs while maintaining optimal particle size distribution and maximizing crushing chamber efficiency. With outstanding high performance and extended service life, our long term durable carbide solutions contribute to more efficient production processes, lower downtime, and consistently high customer satisfaction. We are committed to continuously improving product quality and providing real-time technical support to ensure the best possible results for every customer.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding