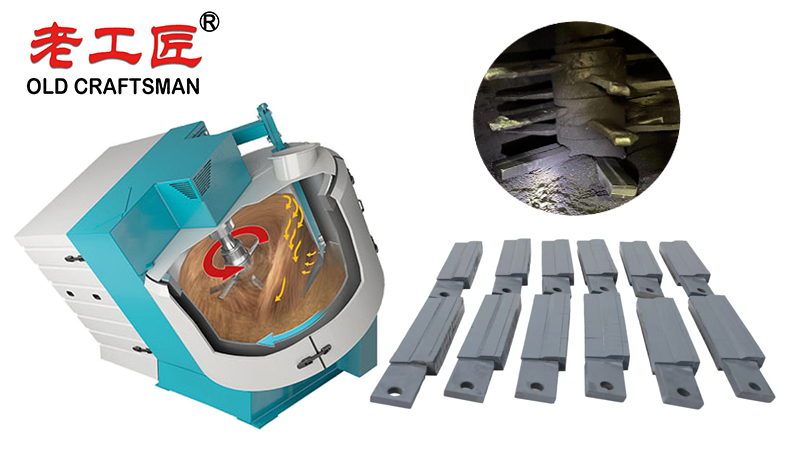

Precision Tungsten Carbide Intensive Mixer Blade is designed for high performance mixing applications where durability, wear resistance, and optimal efficiency are critical. Tungsten carbide (WC) is an extremely hard and dense material, making it ideal for demanding industrial mixing processes, especially in industries like ceramics, powder metallurgy, pharmaceuticals, and advanced materials manufacturing.

Key Features & Benefits:

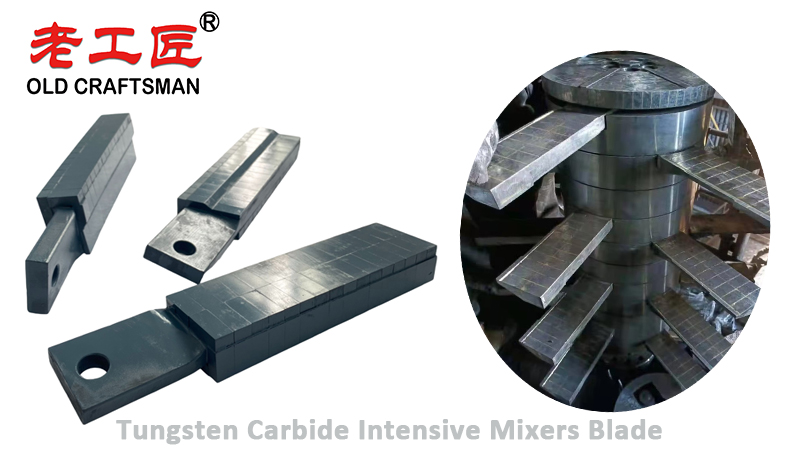

- Exceptional Wear Resistance

- Tungsten carbide is significantly harder than steel, reducing wear and extending blade lifespan even in abrasive environments.

- Ideal for mixing hard powders, ceramics, and other abrasive materials.

- High Strength & Durability

- Maintains structural integrity under high torque and mechanical stress.

- Resistant to chipping, cracking, and deformation.

- Precision Engineering for Optimal Mixing Efficiency

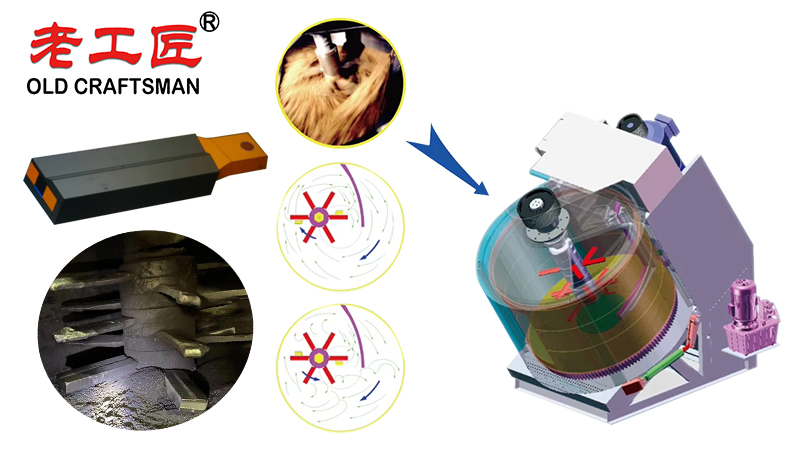

- Custom designed blade geometry ensures uniform mixing with minimal energy consumption.

- Reduces dead zones in the mixing chamber for consistent product quality.

- Corrosion & Chemical Resistance

- Suitable for harsh chemical environments, including acidic or alkaline mixtures.

- Reduced Maintenance & Downtime

- Longer service life compared to steel or coated blades, lowering replacement frequency.

Applications:

✔ Ceramic & Powder Processing (Alumina, Zirconia, Silicon Carbide)

✔ Pharmaceutical & Chemical Mixing

✔ Cemented Carbide & Hardmetal Production

✔ Food Processing (for high wear applications)

✔ Advanced Composite Materials

Why Choose Tungsten Carbide Over Steel?

- 10-20x longer lifespan in abrasive conditions.

- Higher mixing efficiency due to maintained sharpness over time.

- Cost-effective long-term despite higher initial investment.

Customization Options:

- Various blade shapes (sigma, spiral, paddle, etc.)

- Different tungsten carbide grades (fine/coarse grain, binder variations like Co/Ni)

- Coatings (e.g., diamond-like carbon for extra wear resistance)

Carbide intensive mixers equipped with high performance cutting edges made from high strength stainless steel are the preferred choice for applications requiring extreme durability under high temperatures and severe abrasive wear. These mixers, often fitted with clip point blade or clipped point designs and straight edge geometries, excel in processing highly abrasive materials such as cast iron, mineral compounds, and refractory products. The blades and wear resistant parts are manufactured from advanced abrasion resistant and wear resistant materials that offer superior mechanical properties, enabling them to resist material adhesion, thermal expansion, and intensive mechanical stress while maintaining a sharp cutting edge over extended service life. This combination of high quality engineering and robust material selection ensures outstanding performance and long-term reliability in the most demanding industrial environments.

Conclusion:

A precision tungsten carbide intensive mixer blade ensures maximum efficiency, longevity, and performance in demanding mixing applications. For industries where downtime and wear are critical concerns, upgrading to tungsten carbide can significantly improve productivity and reduce operational costs.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding