I. Grades for Carbide Strips

| GRADE | ISO CODE | COBALT CONTENT | DENSITY | HARDNESS |

| (%) | g/cm3 | HRA | ||

| K10T | K05-K10 | 4.5-6.0 | 14.95-15.05 | 92.7 |

| YG8 | K30 | 8 | 14.8 | 89.5 |

| YG6 | K20 | 6 | 14.95 | 90.5 |

| YG6X | K10 | 6 | 14.95 | 91.5 |

| YL10.2 | K30 | 10 | 14.5 | 91.8 |

| YG13X | K30-K40 | 13 | 14.3 | 89.5 |

| YG15 | K40 | 15 | 14 | 87.5 |

*Can adjust the grade according to client onsite using requirement.

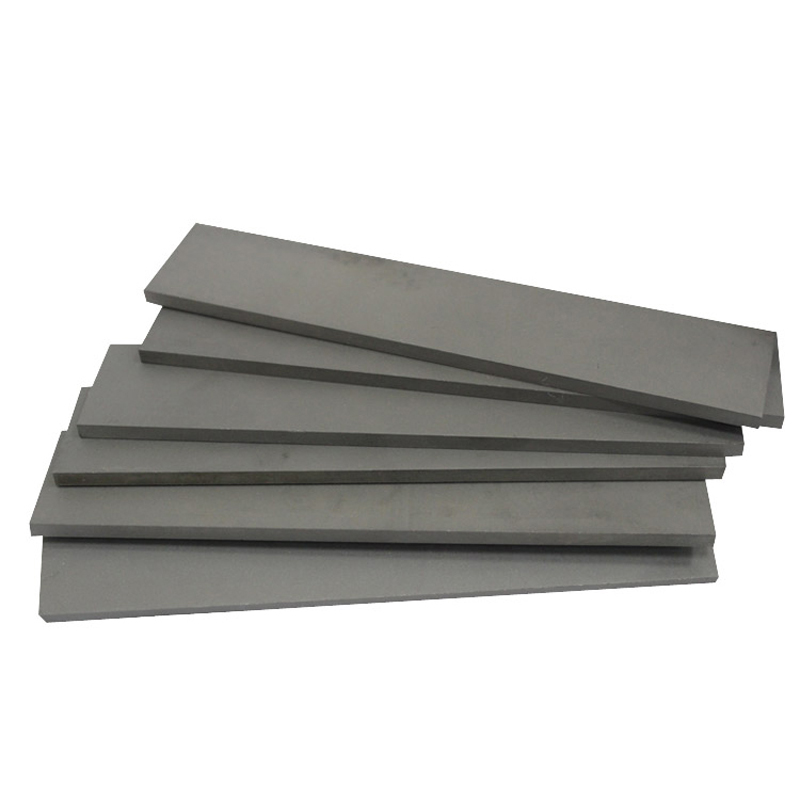

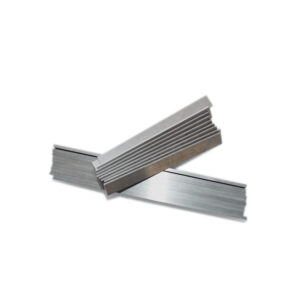

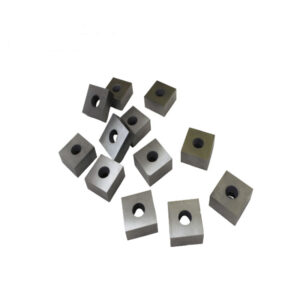

II.Size information for Carbide strips

| Length | Width | Thickness |

| 30-820mm | 2-45mm | 1.0-30mm |

*Sizes can be customized.

III.Advantages of old craftsman Carbide strips:

1. Various grades. We offer Carbide strips that can be used for different applications, such as cutting, grinding, wearing, crushing and so on. Besides, the number/parameter of grade can be adjusted according to the latest product’s testing result carried out by the customer—better customizing.

2. Sufficiency in the kinds of molds. Our factory is available to produce any size of strips—please check above the size information

3. Cost-effective. We choose branded raw materials and HIP sintering, which allows us to produce high and unit quality products.

4. Coherent and complete industrial process. Started from making powder, the products will be strictly tested in each process to ensure their quality. More importantly, our production processes are controlled by ERP and MES system, production and testing data of each batch of products can be traced.

5. Accurate and detailed report. We can provide the quality certificate and measurement report of every specific batch of products.

IV.Application of carbide strips:

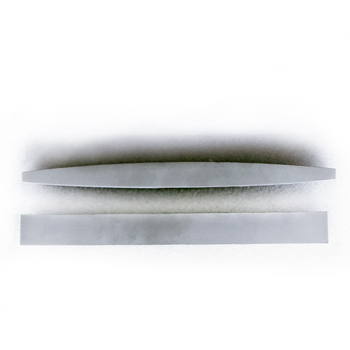

1. Used to make wear-resistant tools. Such as woodworking baldes, plastic crushing baldes, etc.

2. Cut to small pieces to make high-temperature resistant parts, wear-resistant parts, and anti-shielding parts.

3. Used to make Grinding support plate in grinding machine, corrosion-resistant parts in the chemical industry.

4. Used for crusher tools. Such as the hammer blade for sand-making, crushing metals, etc.

5. Different other applications.

V.FAQ

Q: Are customized products your company strong points?

A: Yes. We have 2 CNC machining centers for semi-machining, and the engineer has more than 20 years experience in this field.

Q: What is your MOQ?

A: It depends on the exact products.

Q: Can you design the products according to our detailed usage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.