Conveyor belt downtime is a major productivity killer in mining, aggregate, and material handling operations. Tungsten carbide cleaner solutions offer a high performance option to minimize maintenance interruptions and maximize operational efficiency.

The Problem of Conveyor Belt Downtime

- Unplanned stoppages cost thousands per hour in lost production

- Carryback material accumulation causes belt mistracking and wear

- Frequent cleaner replacement creates maintenance bottlenecks

- Ineffective cleaning leads to roller damage and spillage

Tungsten Carbide Cleaner Advantages

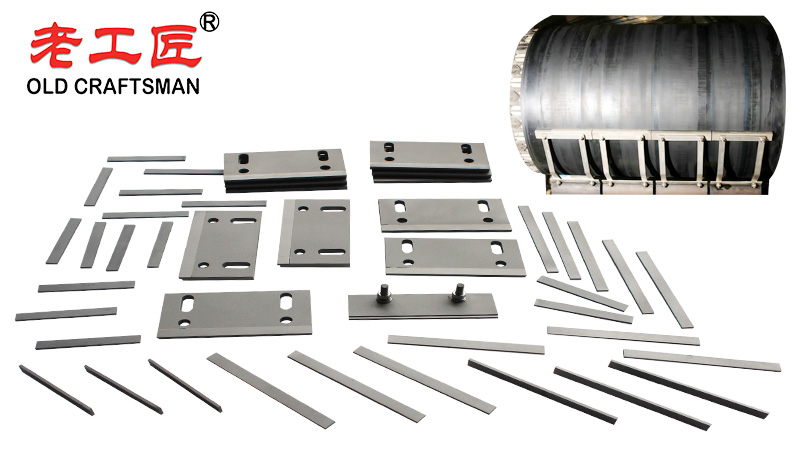

Superior Wear Resistance

- Tungsten carbide lasts 3-5 times longer than standard polyurethane or steel cleaners

- Maintains sharp cleaning edge throughout service life

- Withstands abrasive materials that quickly degrade other cleaners

Enhanced Cleaning Performance

- Aggressive material removal reduces carryback by up to 90%

- Self-sharpening carbide blades maintain optimal cleaning pressure

- Customizable blade designs for different belt conditions

Downtime Reduction Benefits

- Extended service intervals (6-12 months typical)

- Quick-change cartridge systems for faster replacement

- Reduced spillage cleanup requirements

- Less frequent belt and roller replacements

Implementation Considerations

- Proper blade angle adjustment for your specific material

- Correct tensioning to balance cleaning effectiveness and belt wear

- Regular inspection schedule (recommended monthly)

- Compatibility with your belt type and speed

ROI Calculation

While tungsten carbide cleaners have higher upfront costs, the total cost of ownership is typically lower due to:

- Reduced replacement frequency

- Lower labor costs for maintenance

- Increased production uptime

- Extended belt and component life

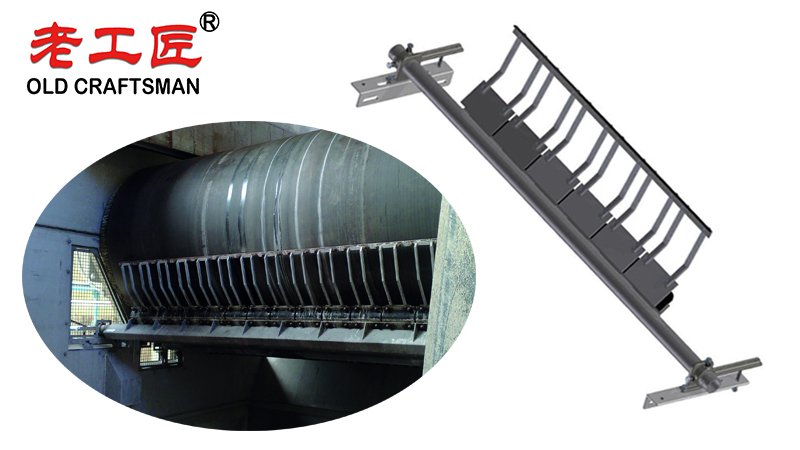

Our heavy duty mining conveyor belt scraper is specifically designed for the toughest bulk material handling environments, delivering high performing cleaning even under high temperature conditions and abrasive materials.

By effectively removing carryback, it significantly improves efficiency, reduces labor costs, and enhances operational efficiency throughout the entire material handling process and material transport cycle. The scraper’s high quality construction ensures it can resist material buildup and wear, providing long term reliability in demanding mining operations.

Integrated into engineered systems for loading and unloading of unit loads or bulk commodities, it helps keep belts clean, minimizes spillage, and allows industrial trucks and conveyor networks to operate safely and efficiently. The result is smoother supply chain performance, lower maintenance downtime, and a cleaner, more productive facility that moves materials efficiently and safely day after day.

Conclusion

High performance tungsten carbide conveyor belt scrapers represent a smart investment for operations looking to minimize downtime and maximize productivity. Their exceptional durability and cleaning efficiency can transform your material handling system’s reliability and cost-effectiveness.

Tungsten carbide secondary scrapers are the optimal choice for mining conveyor systems due to their unmatched wear resistance, efficiency in material removal, and long term cost savings. They help maintain belt longevity, reduce maintenance, and improve operational efficiency in abrasive mining environments.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding