Arc Tungsten Carbide (Arc TC) is a highly effective material for wear lining applications, particularly in industries where abrasion, impact, and corrosion resistance are critical. Here are the key advantages of choosing Arc Tungsten Carbide for wear lining:

1. Exceptional Wear Resistance

- Tungsten carbide is one of the hardest materials available (HV 1500-2000), making it highly resistant to abrasive wear.

- Outperforms traditional materials like chrome steel, ceramic tiles, and even some other hardfacing alloys in high wear environments.

2. Superior Impact Resistance

- Unlike brittle alternatives (e.g., pure ceramics), Arc TC combines tungsten carbide particles with a tough metallic matrix (typically cobalt or nickel-based), providing excellent resistance to chipping and cracking under impact.

- Ideal for applications involving heavy impact, such as mining, mineral processing, and bulk material handling.

3. Corrosion & Chemical Resistance

- The binder matrix (especially nickel-chromium variants) enhances corrosion resistance, making it suitable for wet or chemically aggressive environments.

- Performs well in slurry pipelines, dredging, and chemical processing equipment.

4. Extended Service Life

- Arc TC linings can last 3–10 times longer than conventional steel or ceramic linings, reducing downtime and replacement costs.

- Lowers total cost of ownership (TCO) despite a higher initial investment.

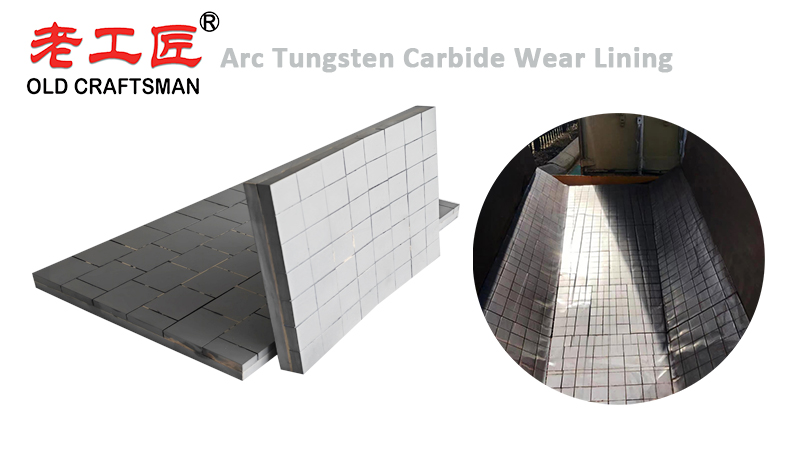

5. Customizable Application Methods

- Can be applied via welding (arc overlay), thermal spray, or as prefabricated tiles/plates, offering flexibility for different equipment geometries.

- Suitable for complex shapes like chutes, hoppers, cyclones, and pump casings.

6. High Temperature Stability

- Maintains hardness and wear resistance at elevated temperatures (up to ~600°C), unlike polymers or some metals that degrade.

7. Reduced Maintenance & Downtime

- Longevity and durability minimize frequent shutdowns for lining replacements, improving operational efficiency.

8. Improved Flow Characteristics

- Smooth, hard surfaces reduce material buildup (e.g., coal, ore, cement), enhancing flow efficiency in conveyors and transfer points.

Typical Applications:

- Mining & Quarrying (crushers, screens, excavator buckets)

- Cement & Power Plants (raw mill liners, cyclone separators)

- Oil & Gas (drilling tools, slurry valves)

- Dredging & Sand Processing (pump housings, pipelines)

Comparison to Alternatives:

| Material | Wear Resistance | Impact Resistance | Corrosion Resistance | Cost Efficiency |

|---|---|---|---|---|

| Arc Tungsten Carbide | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ |

| Ceramic Tiles | ★★★★☆ | ★★☆☆☆ | ★★★★★ | ★★★☆☆ |

| Chromium Steel | ★★★☆☆ | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ |

| Polyurethane | ★★☆☆☆ | ★★★★★ | ★★★☆☆ | ★★★★☆ |

Carbide wear liners are high quality, high performance wear resistance materials specifically engineered for the most demanding industrial applications, including oil and gas, mining, cement, and power generation. Manufactured through advanced manufacturing processes using premium raw materials with precisely controlled particle size, these liners deliver exceptional mechanical properties such as extremely high hardness, outstanding abrasion resistance, superior tensile strength, and high strength overall. Thanks to their uniquely low coefficient of friction and excellent performance in corrosive environments and harsh environmental conditions, carbide wear liners provide long-term protection against abrasive wear, impact, and erosion even over extended periods of time. This combination of properties ensures significantly extended service life, reduced maintenance costs, and improved operational reliability in severe environmental factors where conventional materials fail quickly.

Conclusion:

Arc Tungsten Carbide is an optimal choice for wear lining in harsh environments where abrasion, impact, and corrosion coexist. Its durability, adaptability, and long-term cost savings make it a preferred solution in heavy industries.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear plates, Liners for HPGR Feed Chute and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding