Tungsten carbide blades offer a significant performance and economic advantage over traditional steel blades in intensive mixers. Their primary benefits stem from an exceptional combination of extreme hardness and good fracture toughness, leading to vastly extended service life, consistent mix quality, and reduced operational costs, especially when processing abrasive materials.

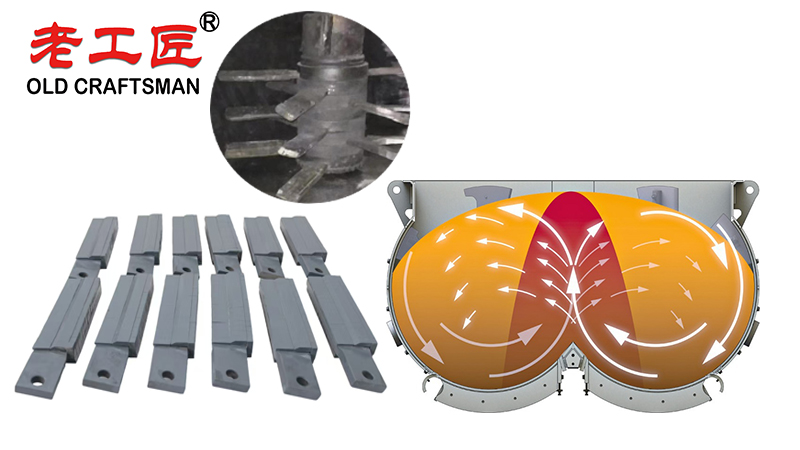

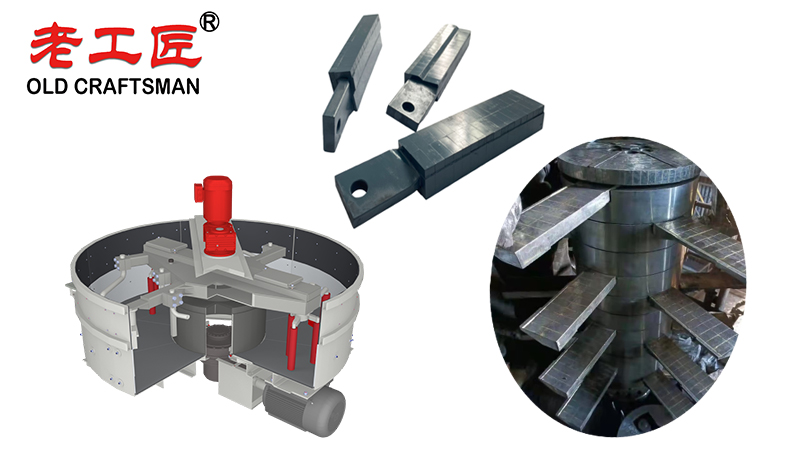

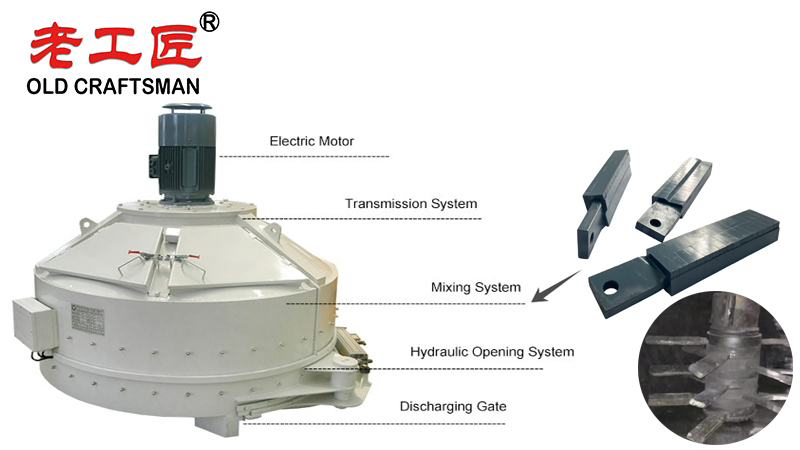

What is an Intensive Mixer?

First, it’s crucial to understand the demanding environment these blades operate in. Intensive mixers (also known as high-shear mixers) are designed to blend, disperse, and knead materials that are often highly viscous, dense, and abrasive. Examples include:

- Rubber compounds (with carbon black, silica)

- Plastics and masterbatches

- Ceramic powders

- Battery electrode slurries

- Adhesives and sealants

In these machines, the blades (or rotors) are subjected to extreme mechanical stress, high temperatures, and constant wear from abrasive fillers.

The Key Advantages of Tungsten Carbide Blades

1. Superior Wear Resistance and Extended Service Life

This is the most significant advantage.

- The Hardness Factor: Tungsten carbide (WC) is a composite material made of hard tungsten carbide particles bonded together by a cobalt or nickel matrix. It is 2 to 3 times harder than hardened tool steel. When processing abrasive materials like carbon black or mineral fillers, steel blades wear down quickly, losing their precise geometry.

- Result: Tungsten carbide blades can last 10 to 20 times longer than their steel counterparts. This translates to dramatically reduced frequency of blade replacement, less machine downtime for maintenance, and lower long term inventory costs for spare parts.

2. Consistent Mix Quality and Dimensional Stability

The performance of a mixer depends on the precise geometry of its blades. As steel blades wear, their clearances and profiles change.

- Maintained Geometry: Because tungsten carbide blades wear so slowly, they maintain their original design geometry and tip clearance with the mixer chamber wall for a much longer time.

- Result: This ensures a consistent shear rate, energy input, and mixing action throughout the entire batch and from one batch to the next over a long period. This leads to superior product uniformity, predictable viscosity, and reliable dispersion of ingredients.

3. Enhanced Corrosion and Chemical Resistance

The cobalt or nickel binder in tungsten carbide provides excellent resistance to many corrosive chemicals.

- Advantage: When mixing materials with acidic or alkaline components, or those that release corrosive by-products at high temperatures, tungsten carbide blades will degrade much more slowly than standard steel blades.

- Result: Reduced pitting and chemical erosion, which further contributes to their long service life and consistent performance.

4. High Compressive Strength and Resistance to Deformation

Intensive mixing generates enormous forces.

- Advantage: Tungsten carbide has a very high compressive strength, meaning it resists deforming or bending under the extreme loads encountered during mixing. This is crucial for maintaining the critical small clearance between the blade tip and the mixer wall, which is essential for effective shearing.

- Result: The blades remain true to their form, ensuring efficient power transfer and preventing catastrophic failure due to physical deflection.

5. Improved Operational Efficiency and Lower Total Cost of Ownership (TCO)

While the initial purchase price of tungsten carbide blades is higher than steel blades, their long term economic benefits are substantial.

- Reduced Downtime: Fewer blade changes mean the mixer is operational for more hours, increasing production capacity.

- Lower Labor Costs: Less frequent maintenance reduces the labor required for disassembly, installation, and calibration.

- Reduced Scrap & Rework: Consistent mix quality minimizes the risk of producing off-spec batches that must be scrapped or reworked.

- Energy Efficiency: Maintaining sharp, precise geometry ensures that energy from the motor is efficiently transferred to the mix, rather than being wasted on overcoming the drag of worn, rounded blades.

Comparison at a Glance: Tungsten Carbide vs. Traditional Steel Blades

| Feature | Tungsten Carbide Blades | Traditional Steel Blades |

|---|---|---|

| Hardness & Wear | Extremely High (10-20x life) | Moderate, wears down quickly |

| Mix Consistency | Excellent & Long Lasting | Degrades as the blade wears |

| Corrosion Resistance | Very Good | Poor to Moderate (requires coating) |

| Impact Resistance | Good (but can be brittle) | Very Good (more ductile) |

| Initial Cost | High | Low |

| Long-Term TCO | Very Low | High (due to frequent replacement) |

| Best For | Highly abrasive materials, continuous operation, critical quality | Less abrasive materials, low budget projects, prototyping |

Important Consideration: The “Brittleness” Factor

While tungsten carbide is incredibly hard, it is more brittle than steel. This means it is more susceptible to chipping or cracking from impact forces (e.g., accidentally dropping a blade or encountering a large, hard foreign object in the mix). Proper handling and ensuring the mixer is free of tramp metal are essential. Modern manufacturing techniques, like using a tougher grade of carbide or engineered designs, can mitigate this risk.

Conclusion

For any intensive mixing application where abrasion is a primary cause of failure, tungsten carbide blades are a superior investment. They transform a high maintenance component into a long life asset, delivering unparalleled durability, consistent product quality, and a significantly lower total cost of ownership. The switch to tungsten carbide is a clear step towards more efficient, reliable, and profitable mixing operations.

Carbide-intensive mixers equipped with high performance cutting tools featuring high speed cut edges are widely used in the manufacturing process of advanced wear resistant materials. These mixers operate effectively at high temperatures, ensuring uniform dispersion of hard carbide particles within high strength, abrasion resistant tool steels or stainless steel matrices. The resulting composite materials exhibit exceptional mechanical properties, particularly outstanding resistance to abrasive wear in demanding industrial applications. By precisely controlling particle size and leveraging the extremely high melting points of carbide particles, manufacturers can produce wear applications such as mining tools, shredding blades, and heavy duty forming dies that offer significantly extended service life even under the most severe high speed and high load conditions.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding