In industries like mining, aggregate processing, cement, and power generation, conveyor systems are the lifeline of material handling. However, these environments are brutal, characterized by abrasive materials, high moisture, and extreme wear. Traditional scraper blades made of polyurethane or steel often fail prematurely, leading to downtime, cleanup costs, and belt damage.

The introduction of Tungsten Carbide Scraper Blades has been a game changer. These blades leverage the extreme hardness and durability of tungsten carbide to deliver unparalleled performance where it matters most.

What Makes an Environment “Harsh”?

A harsh conveyor environment typically involves one or more of the following:

- High Abrasion: Materials like iron ore, granite, sand, and clinker rapidly wear down softer materials.

- Moisture & Corrosion: Wet or slurry-based materials cause rust and degrade components.

- Extreme Temperatures: Hot materials from kilns (e.g., cement clinker) or cold environments can compromise the integrity of polymers and metals.

- Chemical Exposure: Certain materials or cleaning processes can be chemically corrosive.

Key Advantages of Tungsten Carbide Scrapers

1. Exceptional Wear Resistance and Longevity

This is the single most significant advantage.

- The Science: Tungsten carbide is a composite material known for its extreme hardness, typically rated between 8.5 and 9 on the Mohs scale (diamonds are a 10). It is significantly harder than the silica sand and other abrasive minerals commonly conveyed.

- The Result: While a polyurethane blade might last weeks or a few months, and a steel blade slightly longer, a tungsten carbide blade can last for several years. This dramatically reduces the frequency of blade replacements, saving on both parts and labor costs.

2. Superior Cleaning Efficiency & Consistent Performance

- Self-Sharpening Action: Tungsten carbide blades are often designed with multiple, small, sintered carbide tips. As these microscopic tips wear, they break off at a granular level, constantly exposing fresh, sharp edges. This ensures the blade maintains a consistently sharp cleaning edge throughout its entire lifespan.

- Controlled Blade Pressure: Because they are so effective, tungsten carbide scrapers can be used with lower tension against the belt. This leads to more efficient cleaning without the excessive friction that causes premature belt wear.

3. Significant Reduction in Belt Damage

- Problem with Hard Scrapers: Solid steel blades are rigid and can gouge the belt surface, especially if a piece of tramp metal gets trapped.

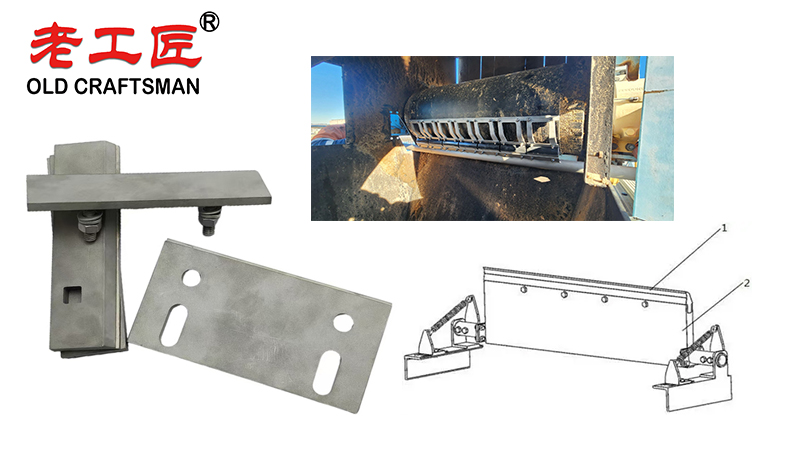

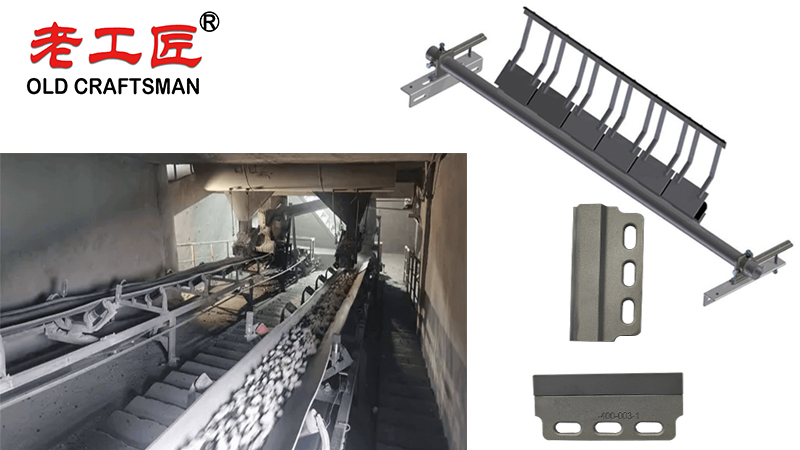

- Advantage of Tungsten Carbide: The scraper systems use a flexible holder (often polyurethane or spring steel) that holds multiple rows of small, individual carbide segments. This design allows the blade assembly to flex and conform to the belt’s surface and splice profiles. If a large, hard object passes under it, the segments can deflect and then return to position, preventing catastrophic damage to the belt.

4. Corrosion and Chemical Resistance

Tungsten carbide is highly inert and resistant to rust and most chemicals. This makes it ideal for:

- Wet and slurry applications (e.g., tailings, sand, and gravel).

- Environments with chemical wash-downs.

- Conveying materials with inherent corrosive properties.

5. Performance in Extreme Temperatures

Unlike polyurethane, which can become brittle in extreme cold or soften and degrade in high heat, tungsten carbide retains its structural integrity and hardness across a very wide temperature range. This makes it suitable for hot material handling in industries like cement and metallurgy.

6. Lower Total Cost of Ownership (TCO)

While the initial purchase price of a tungsten carbide scraper system is higher than traditional options, its long term value is undeniable. The TCO is lower due to:

- Massively extended service intervals.

- Reduced spare parts inventory.

- Less maintenance labor.

- Reduced downtime for changes.

- Protection of the much more expensive conveyor belt from wear and damage.

Comparison Table: Scraper Blade Materials

| Feature | Polyurethane | Steel | Tungsten Carbide |

|---|---|---|---|

| Lifespan | Short (Weeks/Months) | Medium (Months) | Very Long (Years) |

| Abrasion Resistance | Poor to Fair | Good | Excellent |

| Belt Friendliness | Good (when new) | Poor | Excellent (with flexible holder) |

| Corrosion Resistance | Excellent | Poor | Excellent |

| Temperature Tolerance | Limited | Good | Excellent |

| Cleaning Consistency | Degrades quickly | Degrades | Consistently High (self-sharpening) |

| Initial Cost | Low | Low | High |

| Total Cost of Ownership | High | Medium | Low |

Ideal Applications for Tungsten Carbide Scrapers

Tungsten carbide scrapers are not always necessary for every application, but they are exceptionally well-suited for the most demanding ones:

- Mining: Iron ore, copper ore, gold-bearing rock.

- Aggregate: Crushed stone, sand, and gravel.

- Cement & Clinker: Highly abrasive and often hot.

- Coal-Fired Power Plants: Bottom ash and fly ash.

- Recycling: C&D debris, glass, and metals.

- Any application where the cost of downtime and belt replacement is critical.

Designed for the toughest mining environments, our wear-resistant carbide conveyor belt scraper outperforms traditional stainless steel and standard knife steels in every critical area. Thanks to its ultra-hard, fine-grained steel construction with precision carbide edges, it delivers unmatched edge retention and dramatically reduces wear and tear eliminating the constant need for sharpening and dangerous sharp edges that create pinch points.

This specifically designed scraper keeps your conveyor system working at peak operating efficiency while safely moving a wide range of bulk materials, from fine powders to heavy ores. By preventing material buildup and extending belt life, it eliminates frequent maintenance stops, slashes labor costs, and delivers real cost savings of thousands of dollars annually. One simple upgrade, proven results across the entire conveyor system.

Conclusion

In harsh conveyor environments, the choice of a belt scraper is a critical operational decision. While traditional materials represent a low initial investment, they incur high long term costs through frequent replacements, inefficient cleaning, and potential belt damage.

Tungsten carbide conveyor belt scrapers represent a superior engineering solution. By investing in their durability, efficiency, and belt protecting design, operations managers can achieve unprecedented levels of reliability, reduce operating costs, and maximize the lifespan of their most critical asset the conveyor belt itself.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding