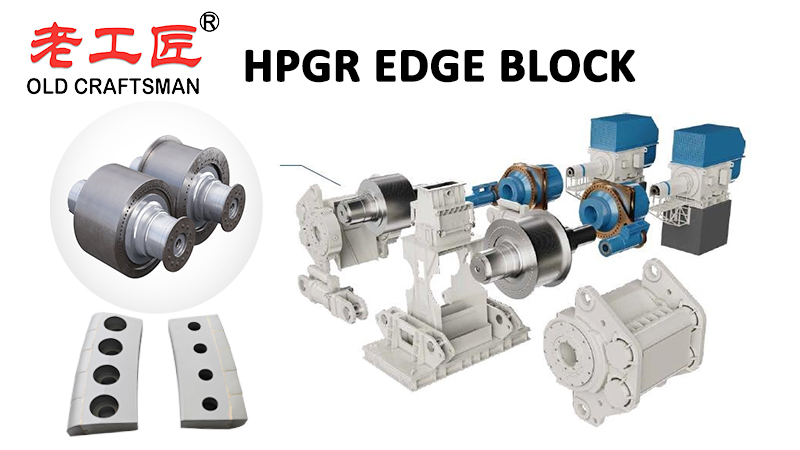

Tungsten carbide edge blocks are widely used in High Pressure Grinding Rolls (HPGR) operations in the mining industry due to their exceptional wear resistance, durability, and performance under extreme conditions. Here are the key advantages of using tungsten carbide edge blocks in HPGR applications:

1. Exceptional Wear Resistance

- Tungsten carbide (WC) is one of the hardest materials available, second only to diamond.

- Highly resistant to abrasion from hard and abrasive ores, such as iron, copper, and gold.

- Extends operational life significantly compared to traditional steel edges, reducing downtime and replacement costs.

2. High Compressive Strength

- Can withstand extreme pressures (up to 300 MPa or more) in HPGR operations without cracking or deforming.

- Maintains structural integrity even under continuous high load grinding conditions.

3. Improved Grinding Efficiency

- Provides a consistent and sharp edge for longer periods, ensuring optimal particle size reduction.

- Enhances throughput and energy efficiency by maintaining a tight grinding gap over extended operation periods.

4. Corrosion and Heat Resistance

- Resists chemical corrosion from moisture and processing additives.

- Maintains hardness and strength even at elevated temperatures generated during grinding.

5. Reduced Maintenance & Downtime

- Longer service life means fewer replacements, reducing maintenance frequency.

- Minimizes unplanned shutdowns, improving overall operational efficiency.

6. Cost-Effectiveness Over Time

- Although the initial cost is higher than steel, the extended lifespan and reduced replacement frequency lead to lower total cost of ownership (TCO).

- Less frequent roll refurbishment translates to long-term savings.

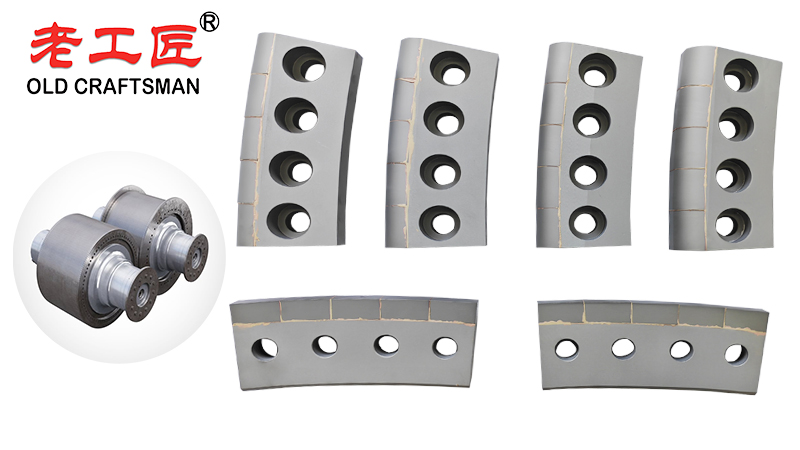

7. Customizable Designs

- Can be engineered in various shapes and sizes to fit different HPGR models.

- Optimized geometries improve ore flow and grinding performance.

The high pressure grinding roll (HPGR) edge block is a critical wear part manufactured from high strength stainless steel through a specialized high temperature production process that ensures superior production quality and long term durability in the grinding process. Several factors influence the edge block’s performance and service life, including operating parameters (pressure, roll speed, moisture), operating conditions, and the design of the edge protection system itself. By optimizing these factors that affect high quality ore comminution, operators can significantly improve productivity, enhance energy efficiency, and implement efficiency measures that reduce operational costs and energy consumption per ton. Proper selection and timely replacement of wear parts, combined with predictive maintenance strategies, play a key role in reducing downtime and extending campaign life. Excellent customer service, rapid spare parts supply, and technical support from the manufacturer further contribute to lowering total cost of ownership while maintaining consistent high strength performance throughout the entire service life of the HPGR edge block.

Conclusion

Tungsten carbide edge blocks are a superior choice for HPGR applications in mining due to their unmatched wear resistance, durability, and operational efficiency. By reducing maintenance needs and improving grinding performance, they contribute to higher productivity and lower operating costs in mineral processing.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding