Tungsten carbide blades represent a significant upgrade over traditional steel blades in intensive mixers. Their primary advantages stem from extreme hardness and exceptional wear resistance, which directly translate into longer blade life, reduced contamination, consistent mix quality, and lower long term operational costs. They are the preferred choice for demanding applications involving abrasive, corrosive, or high viscosity materials.

Detailed Advantages of Tungsten Carbide Blades

1. Superior Wear Resistance and Extended Service Life

This is the most significant advantage.

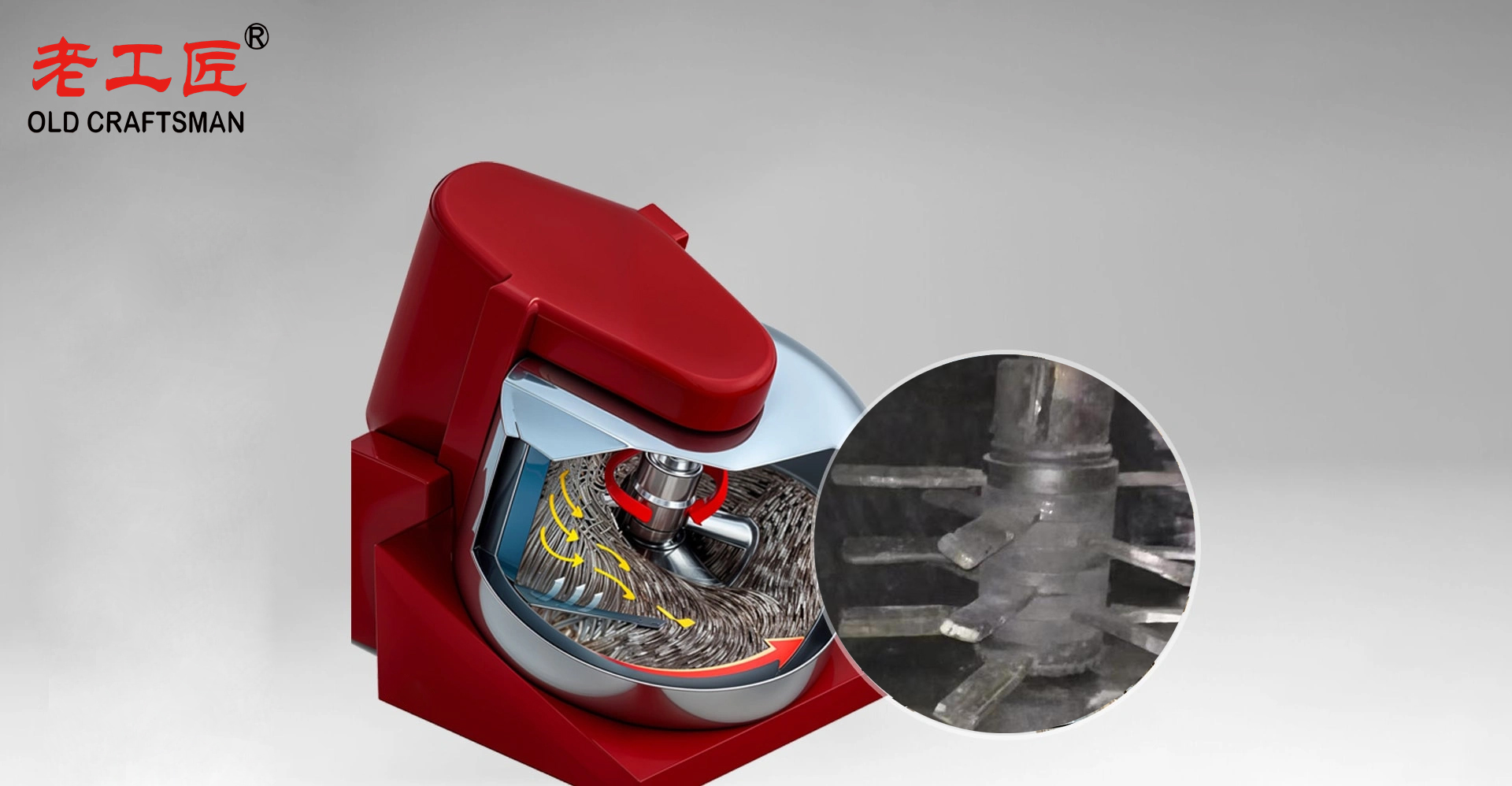

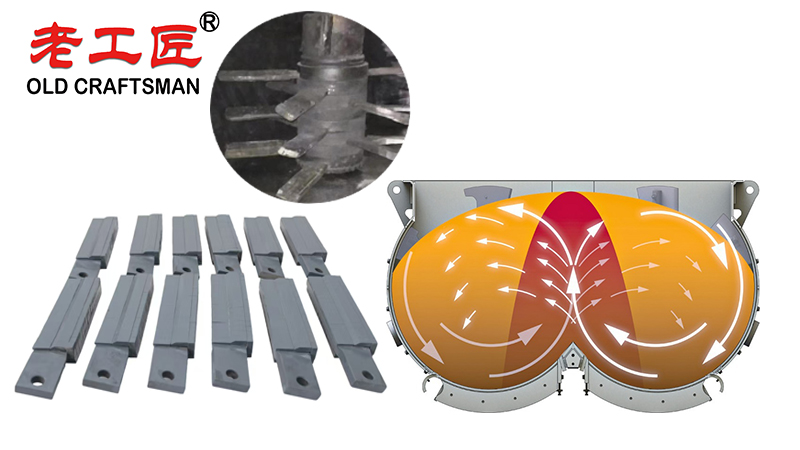

- The Problem: Intensive mixers often process highly abrasive materials like ceramics, minerals, metal powders, reinforced plastics, and battery compounds. Standard steel blades wear down quickly, losing their critical geometry and requiring frequent replacement or re-sharpening.

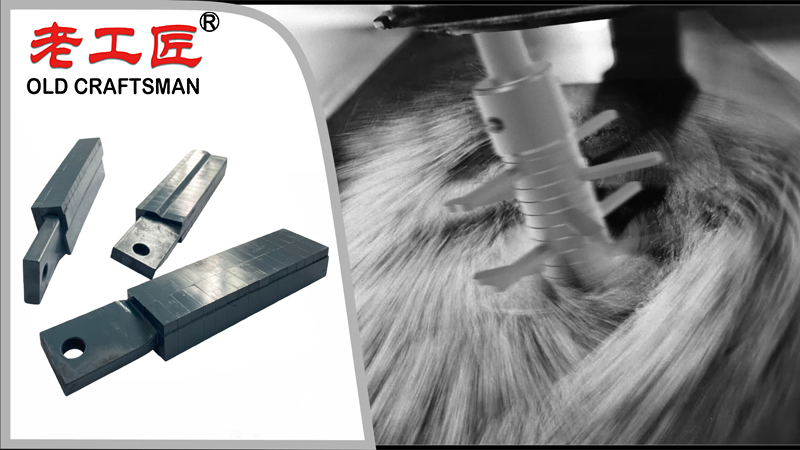

- The Solution: Tungsten carbide is one of the hardest materials available for industrial applications, second only to diamond. Its hardness (typically 85-92 HRA) is multiple times that of hardened tool steel. This means it can withstand abrasive forces for vastly longer periods.

- The Benefit: Blade life can be extended by a factor of 10 to 50 times or more compared to steel blades. This drastically reduces the frequency of blade changes, minimizing production downtime and maintenance labor.

2. Minimized Product Contamination

This is critical for industries with high purity standards.

- The Problem: As steel blades wear, microscopic metal particles are shed into the batch, contaminating the product. This is unacceptable in industries like pharmaceuticals, food, lithium-ion battery production, and advanced ceramics, where even trace metals can ruin a product’s properties or make it unsafe.

- The Solution: Tungsten carbide’s extreme wear resistance means it sheds a negligible amount of material. The blades maintain their surface integrity, ensuring the mixture remains pure.

- The Benefit: Higher product quality, consistency, and yield. It eliminates the risk of batch rejection due to metallic contamination from the blades themselves.

3. Consistent Mixing Performance and Quality

A direct result of maintaining blade geometry.

- The Problem: Worn steel blades change shape over time. This alters the shear forces, mixing action, and energy input into the batch. As a result, the mixing efficiency and final product properties (like viscosity, density, and dispersion quality) can drift from one batch to the next.

- The Solution: Tungsten carbide blades retain their sharp, precise edge and profile for thousands of mixing cycles. This ensures that every batch is subjected to the identical mechanical action.

- The Benefit: Unprecedented batch-to-batch consistency and repeatability. This is essential for maintaining strict quality control standards and producing reliable, high-performance materials.

4. High Corrosion and Chemical Resistance

- The Problem: Many mixed compounds (e.g., certain resins, pharmaceuticals, or chemicals) are corrosive and can attack steel blades, leading to pitting, rust, and accelerated wear.

- The Solution: Tungsten carbide has excellent resistance to a wide range of chemicals, acids, and alkalis. While not universally inert, it is far more chemically stable than steel.

- The Benefit: Enhanced durability in corrosive environments and, again, reduced risk of product contamination from corroded blade material.

5. High Strength and Resistance to Deformation

- The Problem: Intensive mixers operate under high torque and load. Steel blades can bend, deform, or chip under extreme stress or from accidental impact with foreign objects.

- The Solution: Tungsten carbide has a very high compressive strength and modulus of elasticity, meaning it resists bending and permanent deformation under load.

- The Benefit: Greater operational reliability and reduced risk of catastrophic blade failure, which could cause severe damage to the mixer bowl and other components.

6. Lower Total Cost of Ownership (TCO)

While the initial purchase price of tungsten carbide blades is significantly higher than steel blades, this is more than offset by long-term savings.

- Reduced Replacement Costs: Fewer blades need to be purchased over the life of the mixer.

- Reduced Downtime: Less frequent blade changes mean more uptime for production.

- Reduced Maintenance Labor: Less time spent on replacing, re-sharpening, and re-calibrating blades.

- Reduced Scrap/Waste: Consistent quality means fewer rejected batches.

Comparison Table: Tungsten Carbide vs. Traditional Steel Blades

| Feature | Tungsten Carbide Blades | Traditional Steel Blades |

|---|---|---|

| Hardness & Wear Resistance | Extremely High | Moderate |

| Service Life | Very Long (10-50x longer) | Short |

| Product Contamination | Very Low | High (metallic wear debris) |

| Batch Consistency | Excellent | Degrades over time |

| Corrosion Resistance | Good to Excellent | Poor to Fair |

| Impact Resistance | Brittle (can chip) | Tough (can bend) |

| Initial Cost | High | Low |

| Long-Term Cost (TCO) | Low | High |

Key Applications Where Tungsten Carbide Blades Excel

Tungsten carbide blades are not always necessary, but they are invaluable in these demanding scenarios:

- Battery Electrode Production: Mixing abrasive anode/cathode slurries (graphite, lithium cobalt oxide, etc.) where metallic contamination is catastrophic.

- Advanced Ceramics: Processing alumina, zirconia, silicon carbide, and other hard powders.

- Pharmaceuticals: Ensuring purity in high shear granulation and mixing of active pharmaceutical ingredients (APIs).

- Metal Injection Molding (MIM): Mixing metal powders with binders.

- High-Performance Composites: Dispersing carbon fibers, glass fibers, or mineral fillers into resins.

- Paints & Pigments: Dispersing highly abrasive inorganic pigments like titanium dioxide.

Important Consideration: The “Brittleness” Trade-off

The one relative disadvantage of tungsten carbide is its brittleness compared to steel. While it is very strong in compression, it can be susceptible to chipping or cracking from sharp, high impact forces (e.g., hitting a stray metal tool left in the mixer). Proper handling during installation and operation is crucial. Modern engineering, such as using a tough steel substrate with a tungsten carbide coating or tip, often mitigates this issue by combining the hardness of carbide with the toughness of steel.

Conclusion

For any intensive mixing application where abrasion, contamination, and consistency are critical concerns, tungsten carbide blades are a superior investment. Their exceptional durability and performance not only protect product quality but also provide a compelling economic advantage through reduced downtime and maintenance, making them the ultimate choice for modern, high value manufacturing processes.

Our company specializes in the design and manufacturing process of high performance carbide intensive mixers equipped with abrasion resistant blades that withstand extremely high temperatures during operation. These cutting tools, including drill bits with precisely controlled grain size and cut edges, deliver exceptional mechanical properties such as high strength, superior impact resistance, and outstanding abrasive wear resistance even in the most demanding applications requiring continuous heavy duty performance. By using premium cemented carbide instead of traditional stainless steel, our products offer significantly improved corrosion resistance and dramatically extended service life, resulting in substantial cost savings for customers. Every stage of the production process is governed by a rigorous quality management and quality control system to ensure consistent wide range high performance and reliability across all tools and components.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding