Here’s an analysis of the application and advantages of cemented carbide (hard alloy) in refractory brick molds:

Application of Cemented Carbide in Refractory Brick Molds

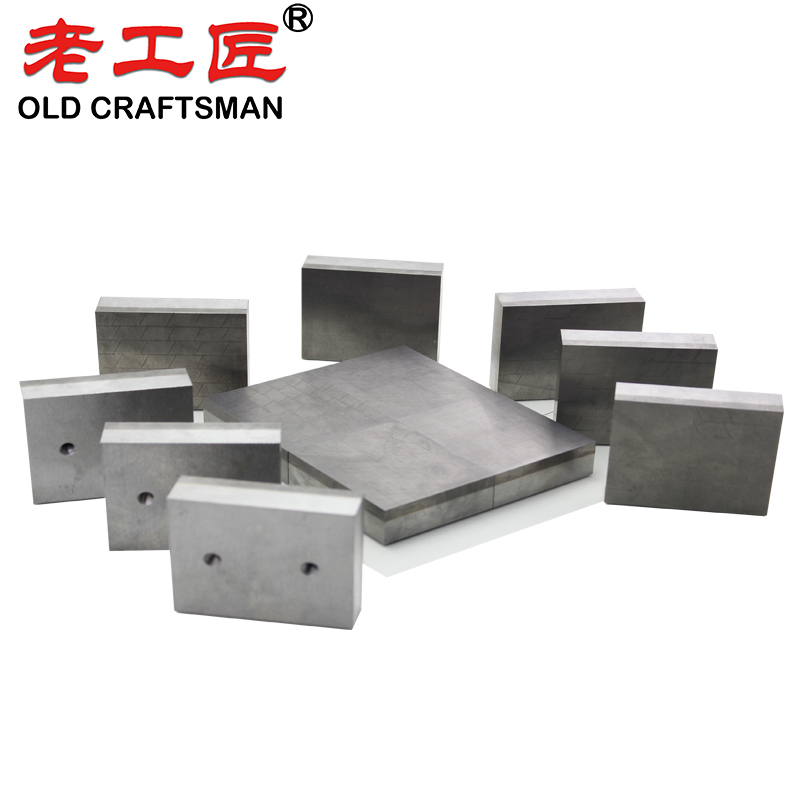

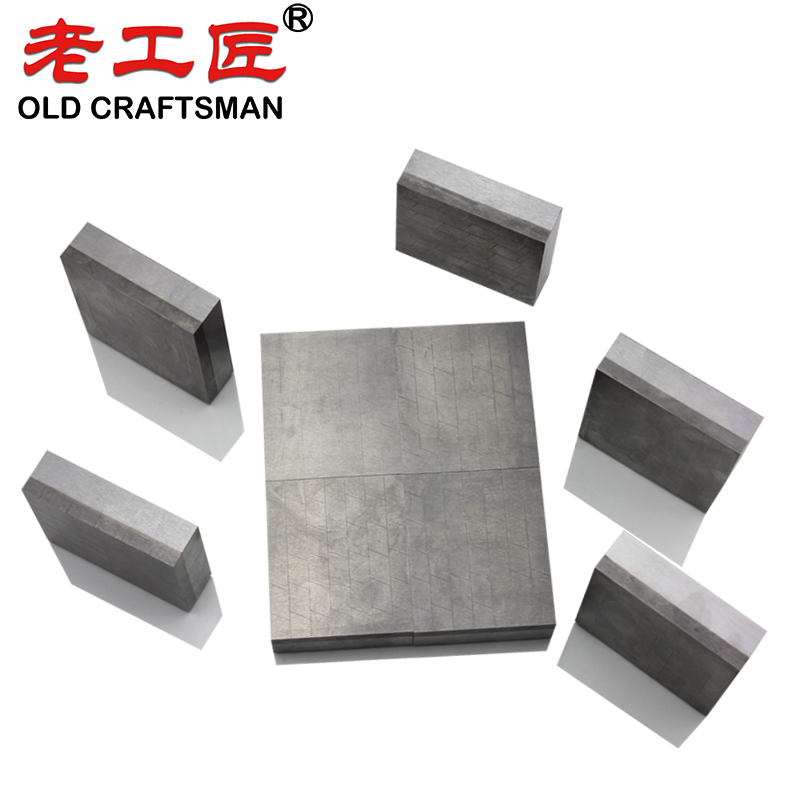

Cemented carbide, a composite material typically made of tungsten carbide (WC) particles bonded with a metallic binder like cobalt (Co), is widely used in the manufacturing of molds for refractory bricks. Refractory bricks are essential in high temperature environments, such as furnaces and kilns, and their molds must endure extreme conditions during production. Cemented carbide is applied in these molds, particularly in critical areas like the mold cavity, pressing surfaces, and wear prone components. Its use is prominent in processes involving pressing, shaping, and forming refractory materials, which often include abrasive compounds like silica, alumina, or magnesia.

Advantages of Cemented Carbide in Refractory Brick Molds

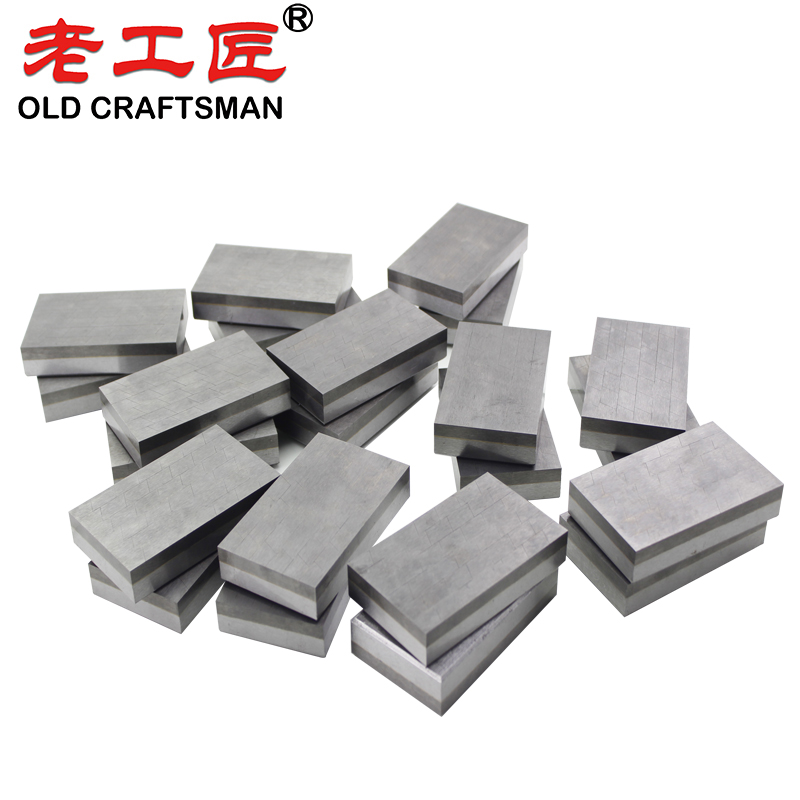

1.Exceptional Hardness and Wear Resistance: Cemented carbide exhibits superior hardness (often exceeding 90 HRA) and resistance to abrasive wear. In refractory brick production, molds are subjected to constant friction and pressure from coarse, abrasive raw materials. Cemented carbide’s durability ensures a longer service life compared to traditional steel or other materials, reducing the frequency of mold replacement.

2.High Strength Under Pressure: The material maintains its structural integrity under the high compressive forces required to compact refractory powders into dense brick shapes. This strength prevents deformation or cracking of the mold during repeated pressing cycles.

3.Thermal Stability: Refractory brick molds often encounter elevated temperatures, either from the process itself or the materials being shaped. Cemented carbide has excellent thermal stability and resistance to thermal fatigue, allowing it to perform reliably without softening or losing its properties in such conditions.

4.Corrosion Resistance: Many refractory materials contain oxides or other chemically aggressive compounds. Cemented carbide’s resistance to corrosion and oxidation ensures that the mold remains intact and functional even when exposed to these harsh substances over time.

5.Precision and Surface Finish: The fine grain structure of cemented carbide allows for precise machining of mold components, resulting in smoother surfaces and tighter tolerances. This precision improves the quality and consistency of the refractory bricks, reducing defects and enhancing their performance in end-use applications.

6.Cost Efficiency Over Time: While cemented carbide molds have a higher initial cost than those made from conventional materials, their extended lifespan and reduced maintenance needs lead to lower overall production costs. Fewer downtimes for mold replacement or repair translate into higher productivity.

Conclusion

The use of cemented carbide in refractory brick molds is a game changer for industries requiring durable, high performance tooling. Its combination of hardness, wear resistance, thermal stability, and precision makes it an ideal choice for producing high quality refractory bricks efficiently and reliably. These advantages position cemented carbide as a preferred material in modern refractory manufacturing, particularly for applications demanding longevity and consistency under extreme conditions.

High-performing mining crusher wear parts are essential for the demanding environment of impact crushers, where high speed feed material enters the crushing chamber and is shattered through intense centrifugal force and severe impact. To achieve optimal size reduction and consistent particle size, these heavy duty components must combine exceptional abrasion resistance, impact resistance, and high strength with proven corrosion resistance, ensuring extended service life even under extreme high temperatures. By choosing strong, wear resistant materials made for tough jobs, operators can lower costs. They can also reduce downtime and keep high quality. This helps maintain maximum productivity in difficult mining conditions.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding