In the demanding world of mining, equipment downtime and maintenance costs are the primary enemies of productivity and profitability. Chutes, which guide the flow of abrasive and impact heavy materials like ore, coal, and slag, are particularly vulnerable. While traditional materials like AR steel (Abrasion Resistant Steel) have been the standard, tungsten carbide chute liners have emerged as the superior solution, delivering unparalleled performance and a significant return on investment.

Here are the key benefits that make tungsten carbide the material of choice for protecting heavy-duty mining equipment.

1. Exceptional Abrasion Resistance

This is the most significant advantage. Tungsten carbide is one of the hardest materials available for industrial use, second only to diamond.

- How it Works: The liner is typically composed of tungsten carbide particles embedded in a tough, wear resistant steel matrix. As abrasive material slides across the surface, it encounters these incredibly hard particles, which resist wear far more effectively than a homogeneous steel surface.

- Result: Tungsten carbide liners can last 10 to 20 times longer than standard AR400 or AR500 steel liners. This dramatically reduces the frequency of liner replacement in high wear areas like transfer points, feed chutes, and slurry lines.

2. Superior Impact Resistance

Mining operations involve large, heavy rocks and materials falling from significant heights. Tungsten carbide liners are engineered to absorb this punishing impact.

- How it Works: The combination of the hard carbide particles and the ductile steel binder creates a composite that dissipates impact energy effectively. Unlike brittle ceramics, which can shatter, tungsten carbide liners are designed to withstand heavy, direct blows without catastrophic failure.

- Result: Reduced risk of liner breakage and damage from falling rocks, ensuring continuous operation and protecting the underlying structural steel of the chute itself.

3. Massive Reduction in Downtime and Maintenance

Every hour a mining operation is stopped for maintenance is an hour of lost revenue.

- Benefit: With a lifespan measured in years instead of months, tungsten carbide liners drastically reduce the number of planned and unplanned maintenance shutdowns required for liner replacement.

- Result: Increased equipment availability and operational uptime, leading directly to higher production output and profitability. Maintenance crews can be allocated to other critical tasks.

4. Enhanced Material Flow and Reduced Blockages

The ultra-smooth, hard surface of tungsten carbide liners creates a low friction environment for material to slide across.

- Benefit: This prevents the build-up of sticky or moist materials that can adhere to rougher steel surfaces. It also minimizes the “scouring” effect where material gets trapped in grooves and accelerates wear.

- Result: A more consistent and efficient material flow, reduced plugging and rat-holing in chutes, and less need for manual intervention to clear blockages.

5. Significant Lifecycle Cost Savings (Lower Total Cost of Ownership)

While the initial purchase price of tungsten carbide liners is higher than traditional steel, their long-term economic benefits are undeniable.

- Cost Analysis:

- Initial Cost: Higher for tungsten carbide.

- Replacement Cost: Drastically lower for tungsten carbide (fewer replacements needed).

- Labor Cost: Drastically lower for tungsten carbide (fewer man-hours for installation).

- Downtime Cost: Drastically lower for tungsten carbide (more production hours).

- Result: When calculating the Total Cost of Ownership (TCO), tungsten carbide liners almost always prove to be the more economical choice over the life of the equipment.

6. Protection of Primary Equipment

A worn-out chute liner doesn’t just fail on its own; it exposes the underlying structural steel of the chute to rapid wear.

- Benefit: By providing a long lasting protective barrier, tungsten carbide liners prevent damage to the much more expensive and difficult-to-replace chute structure.

- Result: Avoids catastrophic structural failures and the exorbitant costs associated with repairing or replacing entire sections of plant infrastructure.

7. Versatility and Customization

Tungsten carbide liners are not a one-size-fits-all product. They are available in various forms to suit specific applications:

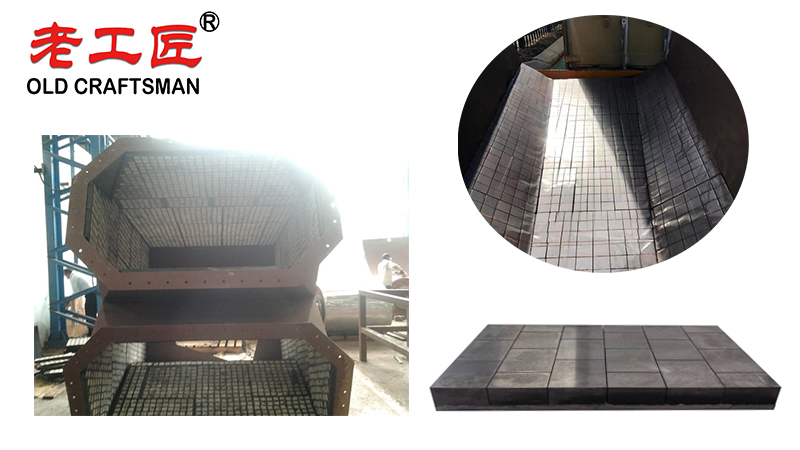

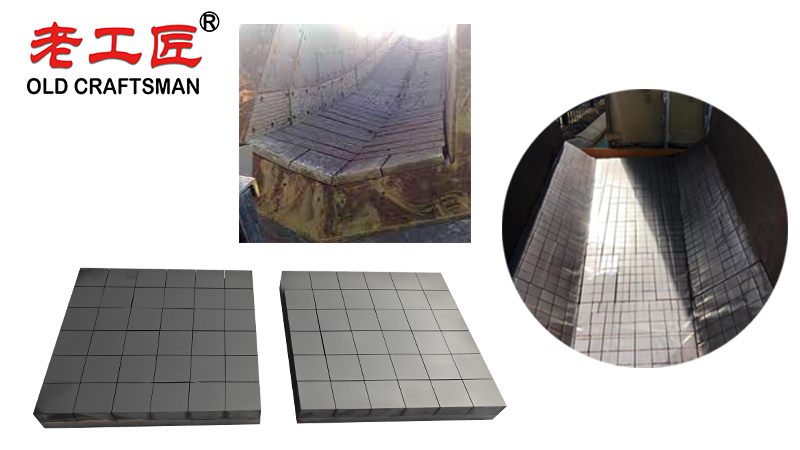

- Tungsten Carbide Tiles/Plates: Bolted or welded onto flat or slightly curved surfaces.

- Tungsten Carbide Overlay (Wear Plate): A steel plate with a layer of tungsten carbide welded onto its surface, offering a good balance of impact resistance and wear protection.

- Custom Shapes: Can be manufactured to fit complex geometries like cyclones, pipe elbows, and radiused chutes.

Ideal Applications in Mining

Tungsten carbide liners are particularly beneficial in areas of extreme wear, such as:

- Primary Crusher Discharge Chutes

- Mill Feed Chutes

- Screening Plant Transfer Points

- Slurry Pipelines and Cyclones

- Hopper Impact Zones

- Skip Loading Chutes

- Cheek Plates

- Wear Resistant Material

- High Pressure Grinding

- Tungsten Carbide Wear

- High Wearing

- Material Flow

- Wear Parts

- Energy Consumption

- Wear Protection

- Iron Ore

- High Temprature

Conclusion

In the relentless environment of heavy duty mining, the choice of wear liners is a critical strategic decision. While traditional materials represent a lower initial investment, they incur high hidden costs through frequent downtime, labor intensive maintenance, and lost production.

Tungsten carbide chute liners represent a shift from a reactive maintenance mindset to a proactive, productivity focused strategy. By investing in their superior abrasion and impact resistance, mining operations can achieve unprecedented levels of uptime, efficiency, and cost-effectiveness, securing a powerful competitive advantage in a tough industry.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding