Tungsten carbide wear resistant liners are vital in loading chutes, primarily due to their outstanding wear resistance and extended service life. Composed of robust materials like tungsten carbide or chromium carbide, these liners are engineered to endure the intense abrasion and impact caused by handling materials such as ore, gravel, or coal. Their exceptional hardness ensures they resist wear far better than conventional materials, making them an ideal protective barrier for chutes exposed to harsh operational conditions.

The importance of their wear resistance cannot be overstated it directly translates to a significantly longer lifespan, reducing the frequency of replacements and maintenance. This durability leads to lower operational costs and less downtime, enhancing overall efficiency in material handling systems. By maintaining the chute’s integrity over time, hard alloy liners ensure consistent performance, prevent premature structural damage, and support uninterrupted material flow, all of which are crucial for maximizing productivity and reliability in demanding industrial environments.

Tungsten carbide wearesistant liners offer several key advantages in mining applications, making them a preferred choice for enhancing the performance and longevity of equipment like transfer chutes. These advantages include:

※ Superior Wear Resistance: Made from materials such as tungsten carbide or chromium carbide, hard alloy liners excel at resisting abrasion and erosion caused by the constant movement of abrasive materials like ore, rock, and coal. This ensures they maintain their integrity even under harsh mining conditions.

※ Extended Service Life: Their exceptional durability significantly prolongs the lifespan of components they protect, such as chutes and hoppers. This reduces the frequency of replacements and repairs, leading to cost savings and less operational downtime.

※ Reduced Maintenance Costs: By minimizing wear and damage to the underlying structure, these liners lower the need for frequent maintenance interventions. This is particularly valuable in mining, where equipment downtime can disrupt production schedules and incur substantial expenses.

※ Improved Operational Efficiency: The robust protection provided by hard alloy liners ensures consistent material flow by preventing chute degradation, blockages, or leaks. This enhances the overall efficiency of material handling processes in mining operations.

※ High Impact Resistance: In addition to abrasion resistance, these liners can withstand the heavy impacts often encountered in mining, such as those from large rocks or high velocity material drops, preserving the structural integrity of the equipment.

※ Cost-Effectiveness Over Time: While the initial investment in hard alloy liners may be higher than standard materials, their long-term performance and reduced replacement needs make them a cost effective solution for mining environments.

These advantages collectively contribute to safer, more reliable, and more economical mining operations, making hard alloy wear-resistant liners an essential component in the industry.

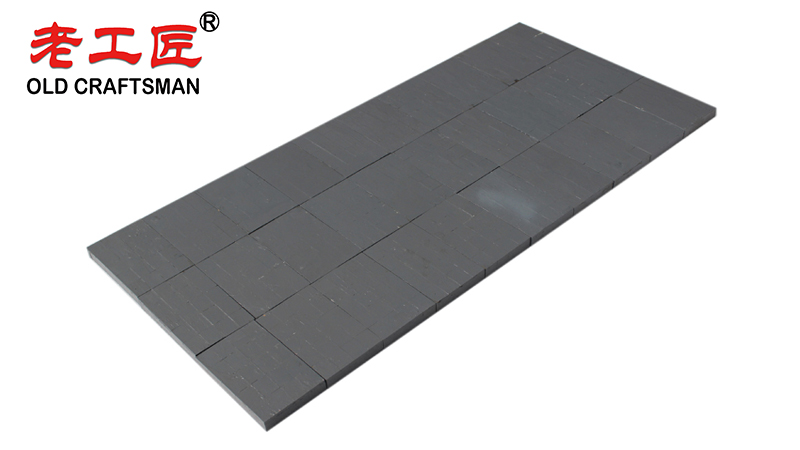

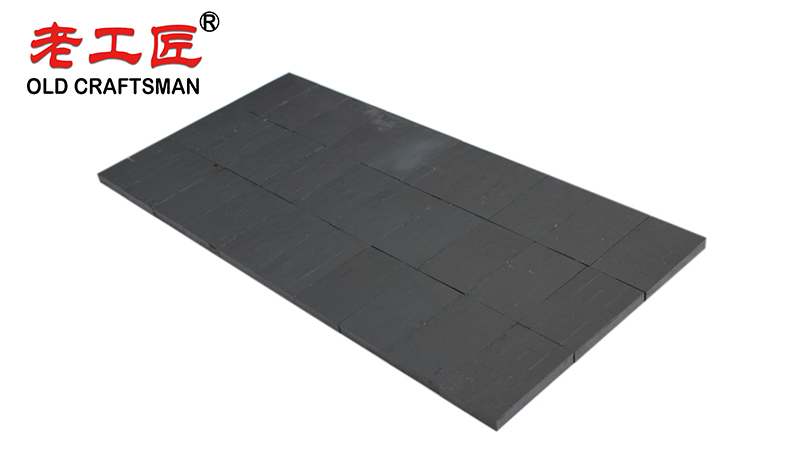

Mining carbide chute liners are high performance wear resistant materials specifically designed for the harshest industrial applications where a wide range of high temperatures, high impact, abrasive wear, and corrosion resistance are simultaneously required. In mining and bulk material handling, these tungsten carbide based liners are widely used as wear plates in chute systems to dramatically extend service life under extreme sliding and impact abrasion conditions. The manufacturing process typically involves powder metallurgy or brazing carbide tiles onto steel substrates, resulting in exceptional hardness, tensile strength, and a remarkably low coefficient of friction against ore, coal, or aggregates.

To evaluate material performance for a specific application, standardized testing methods such as ASTM G65 dry sand/rubber wheel abrasion test, high temperature pin-on-disk tests, and impact abrasion trials are employed to quantify wear rate and overall durability. Compared to conventional hardened steels or ceramic alternatives, mining carbide chute liners consistently deliver superior resistance to abrasive wear and gouging, making them the preferred choice for cutting tools, transfer chutes, and other high wear components in the mining, cement, and power generation sectors.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding