Installation Position

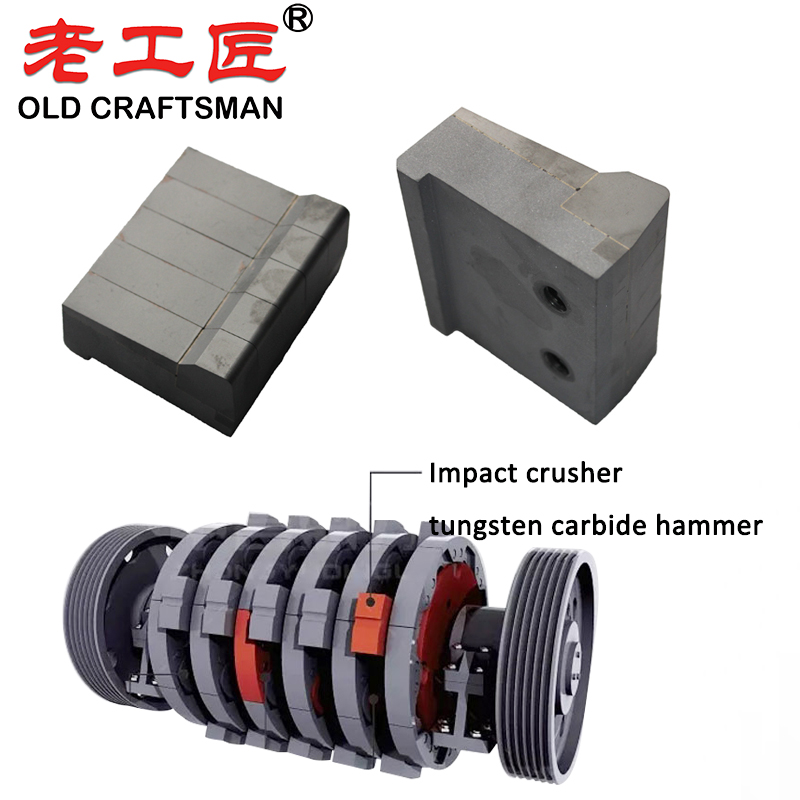

The tungsten carbide crusher hammer is a critical component of a hammer crusher and is typically installed on the rotor of the crusher. It is mounted on the hammer shaft or hammer frame, which is fixed to the rotor assembly. The exact position depends on the crusher’s design, but generally, the hammerheads are evenly spaced around the rotor to ensure balanced operation and effective crushing of materials

Installation Method

- Preparation: Before installation, ensure the rotor and hammer shaft are clean and free of debris or damage. Check that the hammerhead and its mounting components (such as pins, bolts, or locking mechanisms) are in good condition.

- Alignment: Position the hammerhead onto the hammer shaft or frame, aligning the mounting holes (if applicable) with the corresponding slots or fixtures on the rotor.

- Securing: Depending on the crusher model, secure the hammerhead using bolts, pins, or a locking mechanism. Tighten the fasteners to the manufacturer’s specified torque to ensure stability during operation.

- Balance Check: After installing all hammerheads, rotate the rotor manually to check for balance. Uneven weight distribution can cause vibrations or damage, so adjust as needed.

- Final Inspection: Ensure all hammerheads are firmly attached and there is no excessive play. Verify clearance between the hammerheads and the crusher’s inner walls or screens to avoid contact during operation.

For specific crushers, always refer to the manufacturer’s manual, as the exact method may vary based on the equipment design. Proper installation is key to ensuring efficiency and longevity of the crusher.

With decades of years of experience in manufacturing premium wear parts, our mining carbide crusher hammers and tungsten carbide rings are specifically designed for high-speed vertical shaft impact (VSI) crushers and vertical shaft impactors. These high-quality components deliver exceptional durability inside the crushing chamber, ensuring a wide range of application across various feed materials while achieving superior size reduction and consistent finished product size.

Thanks to outstanding high reduction ratios and advanced tungsten carbide technology, our VSI wear parts significantly lower operational costs and maintenance costs, offering unmatched cost-effectiveness for aggregate, mining, and recycling operations. Backed by professional customer service and reliable global supply, we help you maximize crusher performance and minimize downtime – delivering the perfect combination of long service life, high productivity, and reduced total ownership costs.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide crusher hammer and make your crusher hammer use life is tens of times longer than before! We specialize in providing customized carbide solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding